The powertrain design, analysis and simulation team at Southwest Research Institute helps clients develop solutions for engines, powertrains and components. Our experience includes mechanical design, mechanical analysis, and thermodynamic analyses of engine performance using computer aided engineering (CAE) tools such as computational fluid dynamics (CFD) and finite element analysis (FEA).

Powertrain Simulation & CAE Design Solutions

SwRI’s experience ranges from design and development of component and system upgrades to “clean sheet” full-engine designs to meet new product requirements, improve exhaust emissions, increase fuel economy and gain higher power output. Our powertrain simulation services cover internal combustion engines, electric powertrains, hybrid vehicles, and EV batteries, cells and packs.

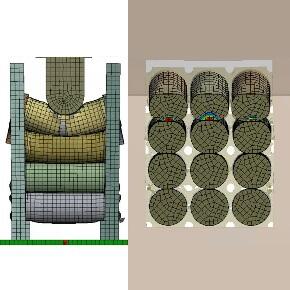

SwRI performs CFD automotive analysis on IC engines, electric powertrains and EV batteries.

Internal Combustion Engine Design & Analysis

- Single Cylinder Engines

- Clean Sheet Engine Design

- Alternative Fuel Conversions

- Performance and Mechanical Development

- ICE and Drivetrain Design Vehicle Integration

- Component and System Design

- Vehicle Failure Modes and Effects Analysis (FMEA)

- Other: specific analysis standards, methodologies

ICE Combustion System Simulation

- Thermal FEA & Cooling System CFD

- Combustion CFD, Knock Prediction and Ignition Modeling

- Structural Dynamics

- Vibration and Modal Analysis

- Fatigue and Durability

- Related Webinar - CHT Analysis for Diesel and Gasoline Engines

Electric Vehicle Design & Engineering

- E-Motor Cooling Simulation

- Analysis for E-Motor Fluids Performance

- Electric and Hybrid Vehicle Design Integration

- Electric Powertrain Packaging and Integration

- Electric Powertrain specific test/analysis standards, methodologies

- Related Webinar - Comprehensive Electric Motor Cooling Modeling

Battery Analysis for Mechanical Abuse

Learn how CAE models are helping analyze lithium-ion batteries, predicting internal short circuit, thermal runaway and fire propagation at cell, module and pack level.

Battery Design Engineering & Analysis

- Battery Thermal Management

- Battery Thermal and Mechanical Abuse Simulation

- Battery Safety Systems Design and Evaluation

- Thermal Runaway Prevention

- Battery Cell Failure Isolation

- Vent Gas Removal

- Related Webinars