Failure Modes

To evaluate the life of components, it is essential to identify the probable failure modes for a given component. The possible failure modes for hot section components include thermal mechanical fatigue (TMF), hot corrosion, creep, and coating oxidation and degradation.

Engineers at Southwest Research Institute (SwRI) examine the parts using state-of-the-art laboratory facilities. They examine hot section parts failed in service and identify the most probable cause of failure.

Life Evaluation Methodology

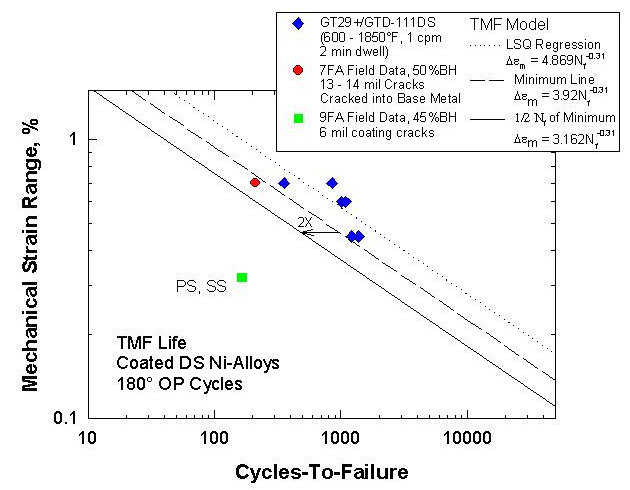

In gas turbines, the life and integrity of the coatings, applied to protect the components from environmental attack and degradation, govern the life and maintenance intervals of hot section components. SwRI has developed state-of-the-art coating and TMF life prediction methods for several substrate/coating systems. The TMF model has been calibrated with service experience and can be used to predict the life of a specific coating on turbine blades in service.

Through an industry consortium program, GTD LIFE software was developed to calculate the remaining life of GE MS5002 engine first-stage buckets. This software is available to turbine users.

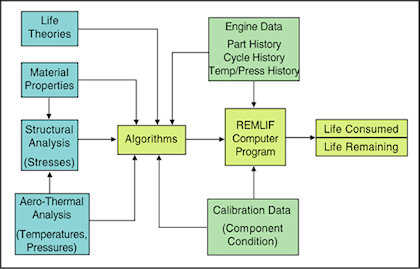

Life Management System Flow Diagram

Flow diagram shows the tasks required to develop a life management system for determining the life of gas turbine components. SwRI is one of the few organizations capable of performing each step in the development of these systems.

Flow diagram shows the tasks required to develop a life management system for determining the life of gas turbine components. SwRI is one of the few organizations capable of performing each step in the development of these systems. Metallography Results

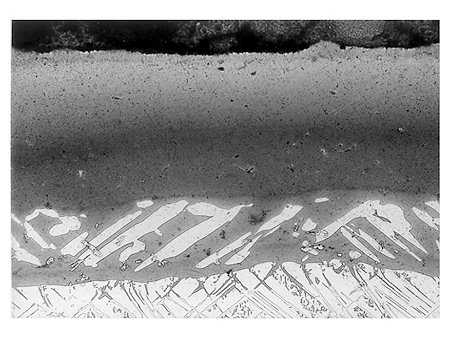

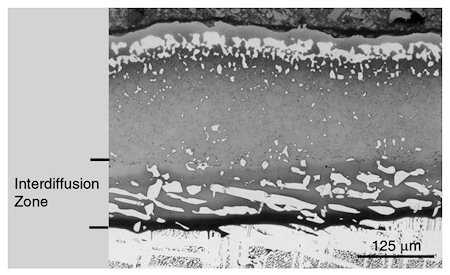

The images above show in-service degraded coating of a 7FA blade (first image) and a 9FA blade (second image) after 21,000 hours of service.

The images above show in-service degraded coating of a 7FA blade (first image) and a 9FA blade (second image) after 21,000 hours of service. COATLIFE Calculation

TMF model validation for Frame 7FA and 9FA blades. Model prediction is in good agreement with metallographic results.

TMF model validation for Frame 7FA and 9FA blades. Model prediction is in good agreement with metallographic results. SwRI can offer you a full range of capabilities and experience in gas turbine technology including becoming an extension of your engineering department.

Contact us for more information about our gas turbine life evaluation capabilities. To contract with SwRI, please contact the Machinery Services Hotline at +1 210 522 3000.

For more information, contact Grant O. Musgrove or call +1 210 522 6517.