The vast variety of testing performed at the Flow Component Testing Facilities (FCTF) over the past 30 years gives SwRI experience designing and building setups that are customized for a specific product or purpose. A range of services can be offered to support custom testing:

- Flow loop design (liquid or gas)

- Equipment, piping, and instrumentation selection

- Controls, automation, and data acquisition

- Mechanical design and fabrication

- Test setup construction and commissioning

Design & Installation

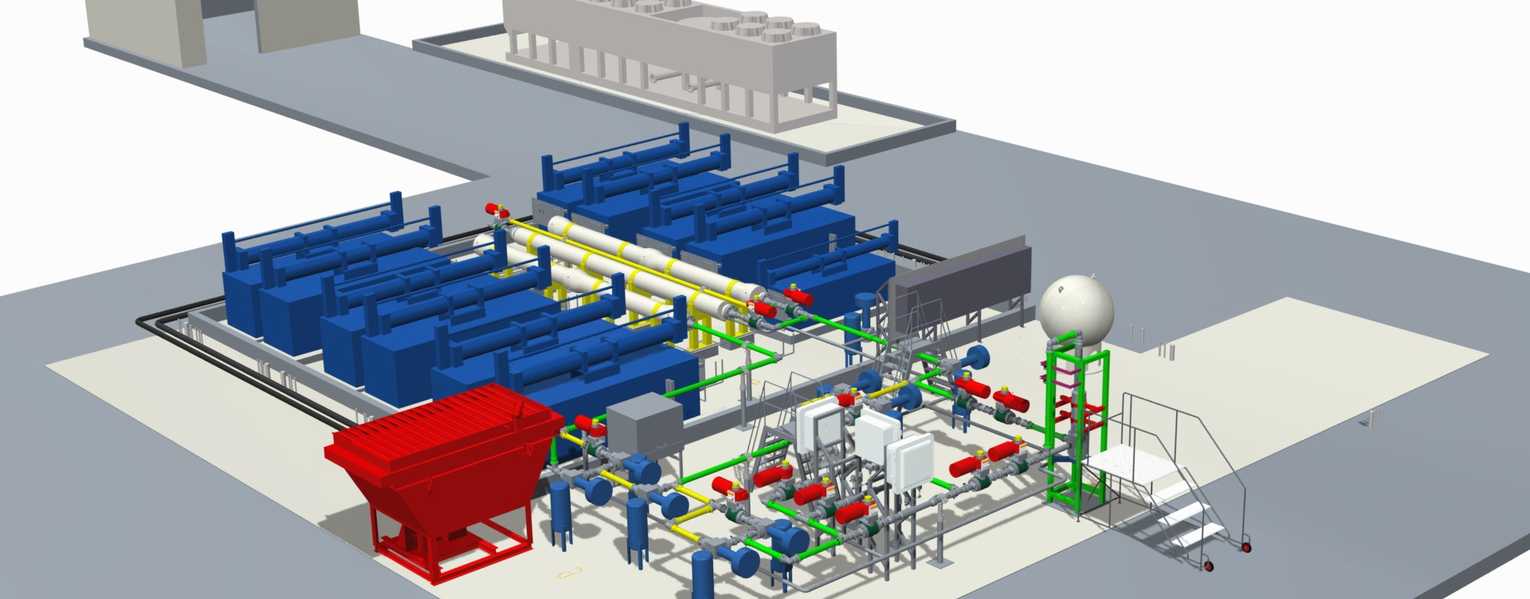

To complement our design capabilities, SwRI offers a custom flow loop design and installation service. For clients looking to operate their own test facility, SwRI can design and commission a test setup intended for installation at a client facility.

Custom Flow Loop Design & Specification

A test rig can be designed to perform testing to an industry standard, or to standards that are unique to a specific company, or product. SwRI specializes in designing custom data acquisition and controls systems, focused on safety, for automation of the completed flow loop.

Flow loop design can include (but is not limited to) considerations such as:

- Addition or removal of heat

- Mechanical design of test fixtures to simulate real-world conditions

- Different flow mediums (inert gases, hydrocarbon gases, oils, water, non-Newtonian fluids, particulate slurries, etc.)

- Requirements for fluid mixing

- Automation

- Safety

Construction & Commissioning

SwRI has the necessary expertise to build and commission a test rig at the FCTF. Test rigs can be built in modules for ease of assembly, disassembly, and shipping. SwRI can build the test rig, commission it, and test for functionality in our laboratory. Turnover to the client can include:

- Installation of test rig at client facility by SwRI personnel

- Operating and procedure manuals

For more information about custom flow loop design, please contact Angel Wileman at +1 210 522 2657.