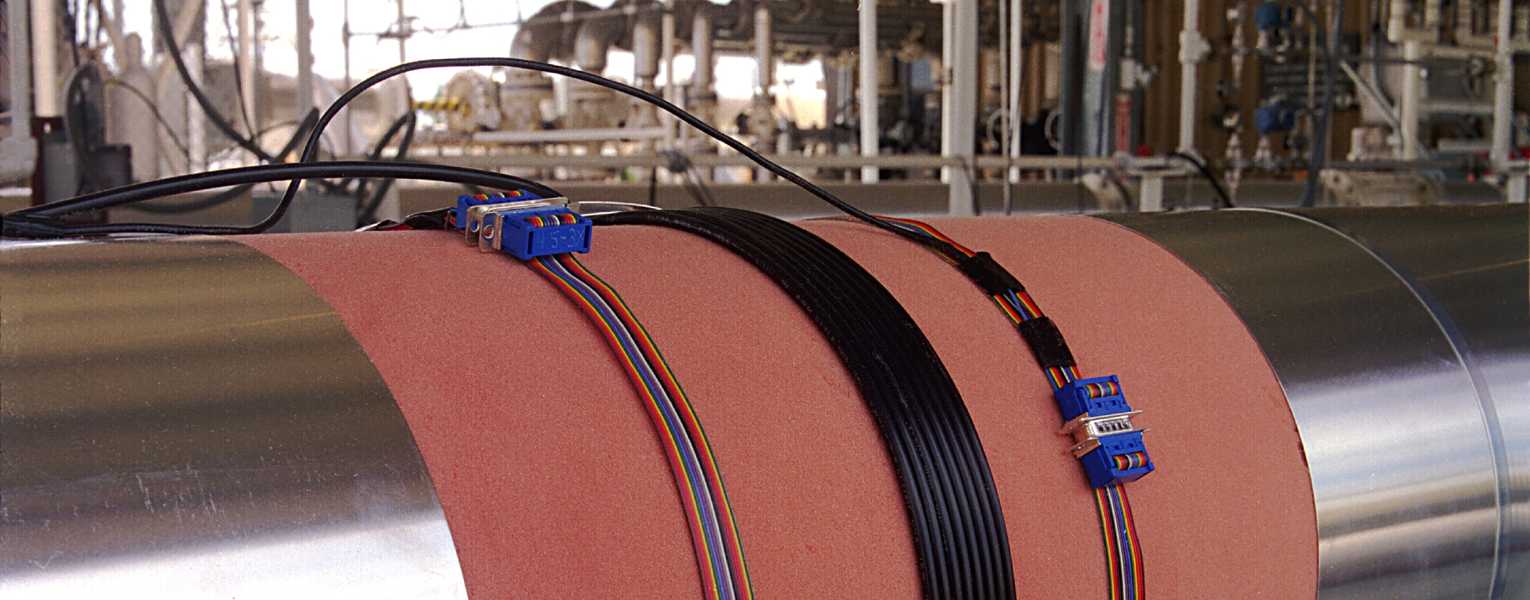

Using eddy currents and other electromagnetic methods, our engineers develop nondestructive solutions for inspecting aircraft structures, pipelines and coating thickness. We apply computer modeling, reliability studies, position sensing, and stress measurement. Our eddy current probe arrays inspect performance, speed, and coverage.

NDE with Electromagnetics

- Conventional eddy current

- Remote field eddy current

- Pulsed eddy current

- Electric current perturbation

- Computer modeling

- Inspection reliability characterization

- Quantitative characterization of NDE system performance

- Probability of detection

- Specialized procedure development

- Barkhausen noise techniques

- Nonlinear harmonics

- Permeability measurements

Electromagnetic Applications

- Computer modeling

- Reliability studies

- Specialized procedure development

- Specialized nondestructive evaluation (NDE) system development

- Position and orientation sensing

- Stress measurement

- Barkhausen noise techniques

- Magnetically induced velocity-change (MIVC) techniques

- Nonlinear harmonics

- Reversible permeability

- Strain gauge measurement

Electromagnetics Capabilities and Past Projects

Selected electromagnetics capabilities and projects include:

- Using ECP for second-layer inspection of fastener holes on aircraft structure

- Magnetic property measurement of selected pipeline steel specimens

- Cladding thickness sensor

- Three-dimensional eddy current signal visualization

- Coating thickness measurement

- Remote-field eddy current

- Cast iron graphitization measurement device