Oxy-fuel combustion is a fairly new approach to power generation. The process uses air that is stripped of other elements like argon and nitrogen until it’s highly concentrated oxygen. It is then combined with a fuel, usually either coal or natural gas, into a stream of carbon dioxide (CO2) inside a combustor. The fuel and O2 chemically react, and the resulting CO2 and H2O steam pushes a turbine that generates power.

A major benefit of the oxygen-rich combustion is also that it results in pure CO2 that can be captured within the power plant and reused or stored rather than released into the atmosphere as a pollutant. The captured CO2 has many possible applications in a number of areas—it could be used in refrigeration and cooling or to create carbonation in soft drinks in addition to a number of uses in the oil and gas industry.

Oxy-Fuel Combustion Carbon Capture

Southwest Research Institute (SwRI) is involved in multiple projects testing the advantages of coal and natural gas in the oxy-fuel combustion power generation process. Natural gas is a highly efficient fuel that combusts well without being especially dangerous to handle and can easily be converted into a liquid.

Coal is an abundant natural resource that can be stored and transported fairly easily. While it’s known for creating harmful greenhouse gas emissions when used for fuel, coal is a fairly clean fuel when used in oxy-fuel combustion. With support from the U.S. Department of Energy, SwRI researchers are currently designing a coal-powered oxy-fuel combustion carbon capture pilot plant.

The main results of the process with both fuels are CO2 and water, and more than 90% of the CO2 emissions are captured and stored.

Direct-Fired Oxy-Fuel Combustion

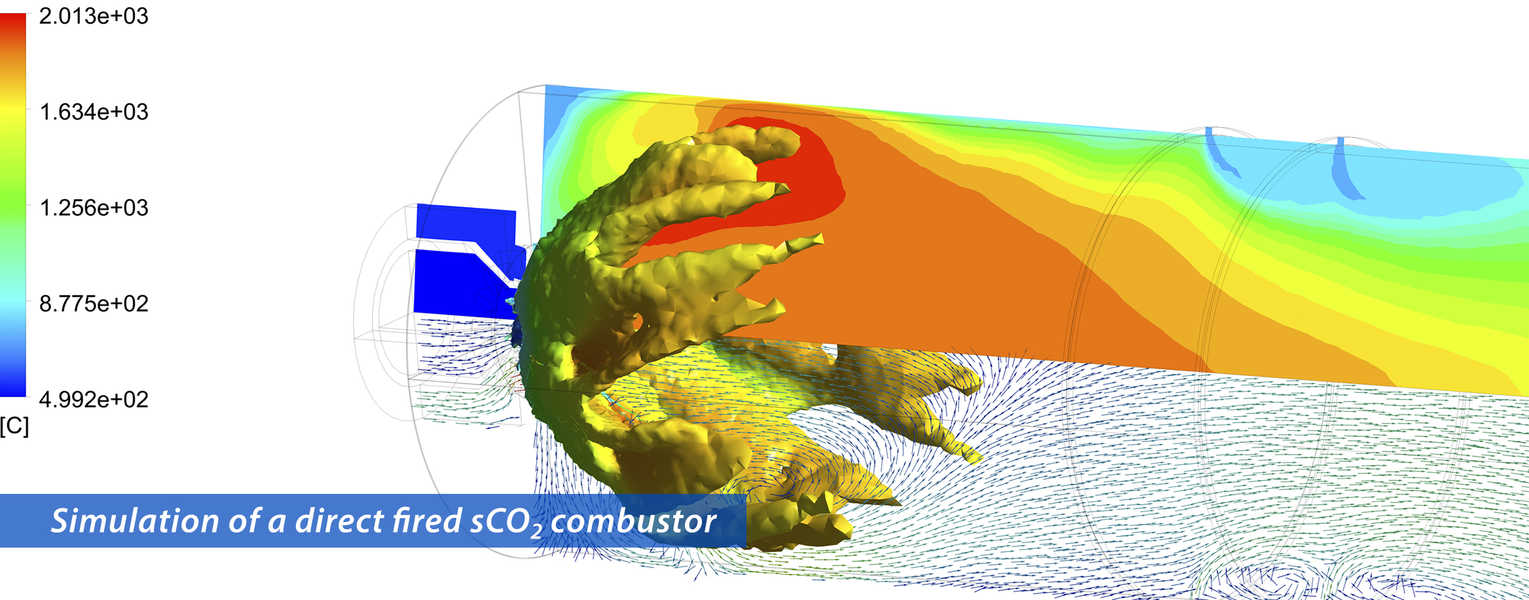

Supercritical carbon dioxide (sCO2) is carbon dioxide held above a critical temperature and pressure, which causes it to act like a gas while having the density of a liquid. It’s also nontoxic and nonflammable, and its supercritical state makes sCO2 a highly efficient fluid to generate power because small changes in temperature or pressure cause significant shifts in its density.

Direct-fired sCO2 power cycles combine sCO2 technology with oxy-combustion. This technology allows for efficient capture of nearly 100% of the CO2 emissions. SwRI is partnering with the U.S. Department of Energy, commercial clients and universities to develop various technologies that will advance direct-fired oxy-fuel combustion, including megawatt-scale and bench top-scale direct-fired combustion test equipment. Researchers will use optical lenses and laser systems to visualize the process and validate models. The end result will be data that can be used to create power generation equipment for direct-fired sCO2combustion.