Microbial influenced corrosion (MIC) is an area of great concern with respect to the longevity of structural materials, fuels, mechanical equipment and containment vessels. This form of corrosion is understood industry-wide and is a result of environmental microbes harvesting carbon sources or trace minerals/metals from sources such as hydrocarbons, steel pipes, polymers, tanks and other metal fixtures. Allowing these microorganisms to thrive leads to costly degradation and expensive reconstruction and/or abatement.

Microbial Influenced Corrosion (MIC) Applications

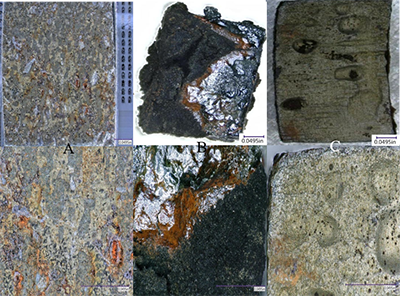

Digital microscopy of microbial influenced corrosion material testing.

Scientists at Southwest Research Institute (SwRI) go into the field to directly collect samples or train and provide equipment and materials for on-site staff to perform collections of suspect microbial or microbiologically influenced corrosion samples. We support clients in the oil and gas industry, military and other sectors, testing materials under different dynamic and stagnant conditions and evaluating additives, biocide regimes and disinfectants to mitigate and inhibit microbial growth. Additionally, other forms of sampling and analysis might include isokinetic air sampling, water sampling, biofilm sampling, or fuel/oil/water interface sampling. The materials or targets in which we primarily study MIC include:

Substrates: paints, metals, fuels, storage tanks, pipelines, and coupon tests

Analysis techniques: growth studies in unique environments (e.g., microaerophilic, sulfate-reducing bacteria, sour-gas, high-pressure), lab-scale (bench-top and environmental chamber), field studies and microbial monitoring with Adenosine Triphosphate (ATP) testing, member filtration, growth promotion studies and microsopy.

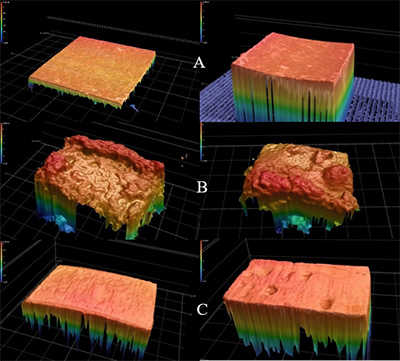

3D thickness imaging of corrosion causing biofilm.

Method Guidance

- MIL-STD-810F: Environmental Engineering Considerations and Laboratory Tests

- NACE TM0194: Field Monitoring of Bacterial Growth in Oil & Gas Systems

- ASTM E1259: Evaluation of Antimicrobials in Liquid Fuels Boiling Below 390°C

- ASTM D6974: Enumeration of Viable Bacteria and Fungi in Liquid Fuels

- ASTM D6469: Microbial Contamination in Fuels and Fuel Systems

- ASTM D7463: ATP Content of Microorganisms in Fuel, Fuel/Water Mixtures and Fuel-Associated Water

- ASTM D7687: Measurement of Cellular ATP in Fuel and Fuel-Associated Water with Sample Concentration by Filtrations

- ASTM D4412: Standard Test Methods for Sulfate Reducing Bacteria in Water and Water Formed Deposits

- Microscopy (e.g., surface attachment, pitting characteristics, biofilm development)

- Light 3D microscopy

- ESEM – Environmental Scanning Electron Microscopy

- SEM – Scanning Electron Microscopy

- Surface Profilometer

- Energy Dispersive Spectroscopy (EDS)-elemental analysis

- Raman Microscopy

- FTIR – Fourier-transform infrared spectroscopy

Anaerobic sulfate-reducing bacteria quantification as evidenced by the black precipitate of iron (II) sulfide.

Related Services

- Corrosion Science & Process Engineering

- Corrosion Detection Sensor Research

- Corrosion Testing Laboratory

- Salt Spray Test Services

- Stress Corrosion Cracking

- Sulfide Stress Cracking (SSC) Testing

Or call Spring Cabiness at +1 210 522 6229.