Progress supports high-quality, R&D-style manufacturing for products that operate in extreme environments, from deep sea to deep space.

- Manufacturing software for small and medium-sized companies

- Manage stock, travelers, documents, and calibrated equipment

- Available as a cloud application or site license

Manufacturing Software Features

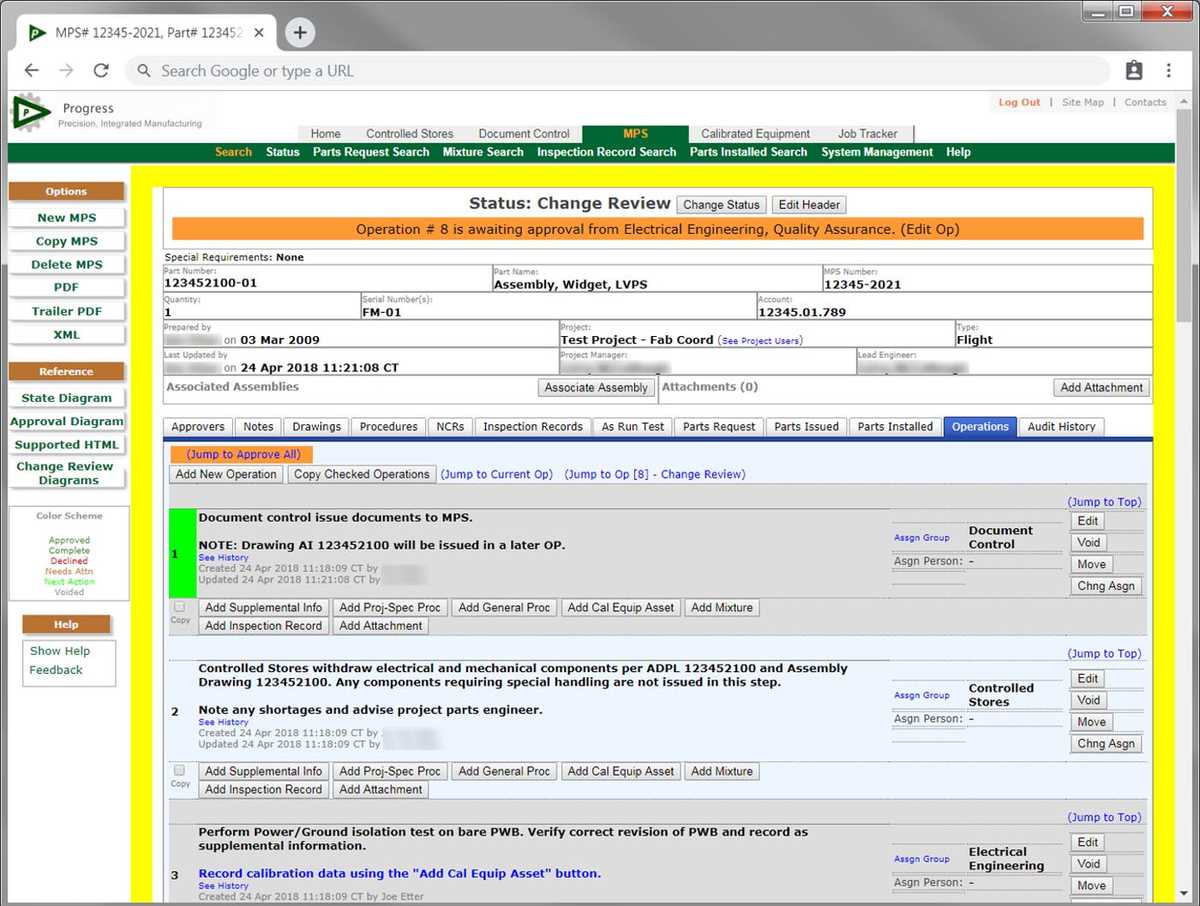

Manufacturing Planning Sheet (Traveler)

The Manufacturing Planning Sheet (MPS) provides functions to create and manage travelers (manufacturing work orders), provide real-time MPS status displays, electronic signatures, track part shortages, manage mixtures, associate calibrated equipment, and many other functions.

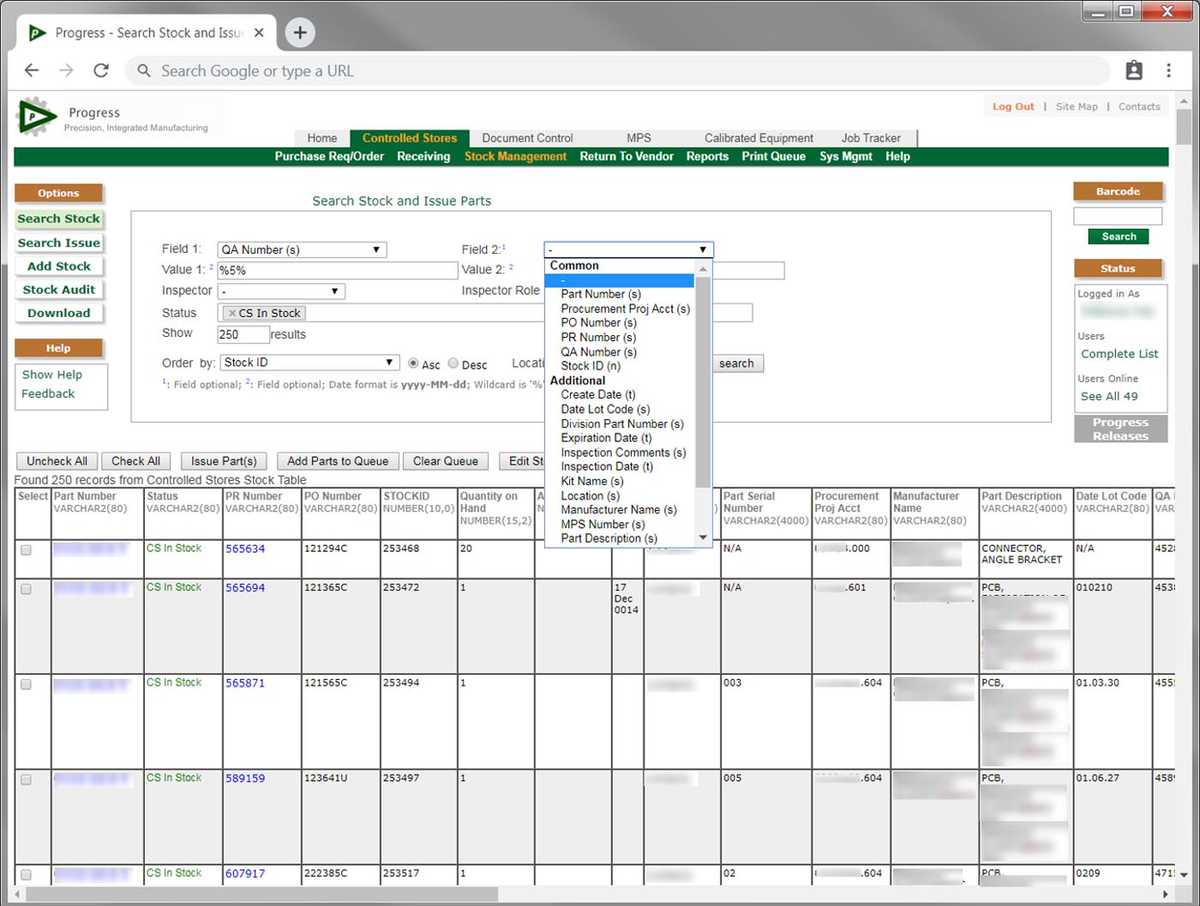

Controlled Stores (Stock Management)

Receive, track, issue and return stock. Advanced features include quality assurance receiving functions, management of end-item data packages, stock serialization, history tracking, functions to integrate stock with travelers, customized reporting, and more.

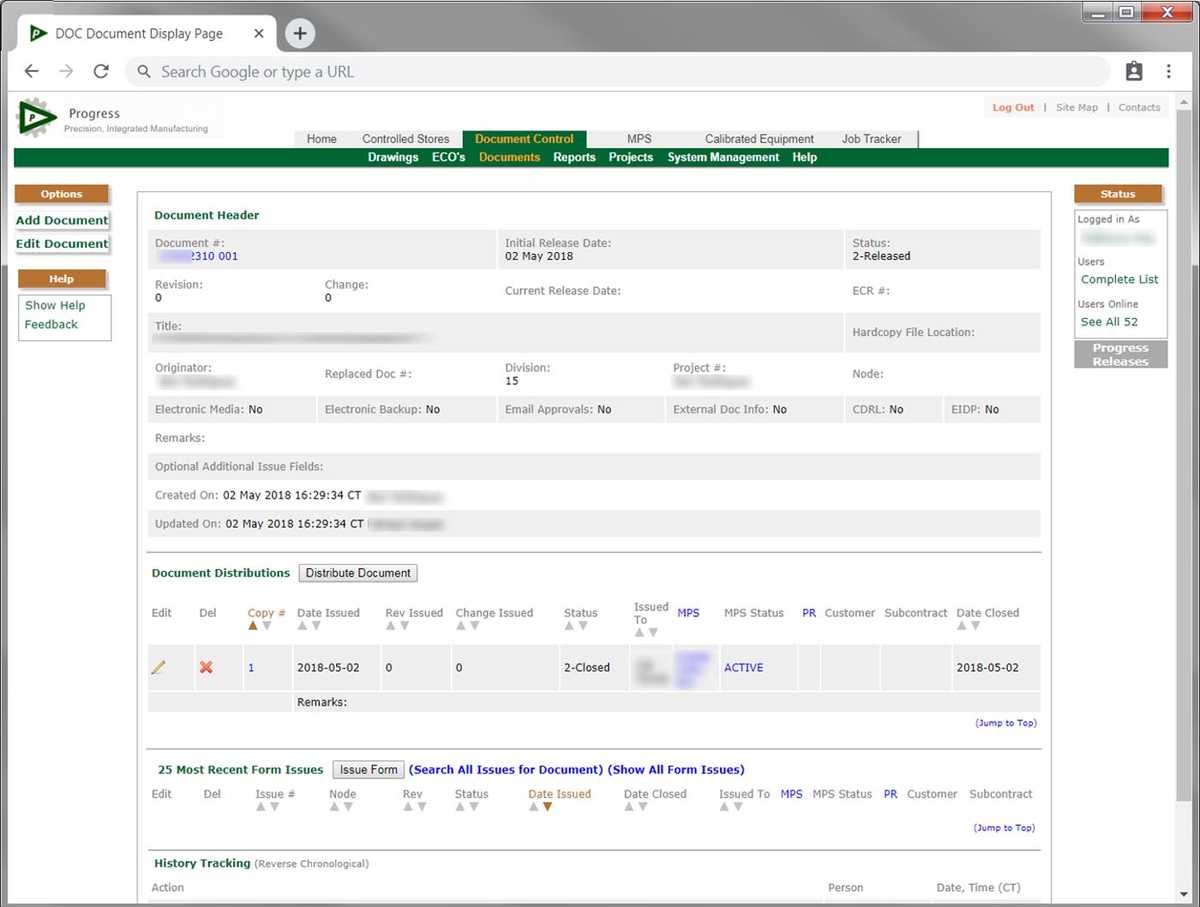

Document Control

The Document Control module provides functions to manage Drawings, Engineering Change Orders (ECOs), Documents, and associated forms. Additional functions include drawing tree management, tracking document distributions and issuing forms, electronic signatures, customer reports, and more.

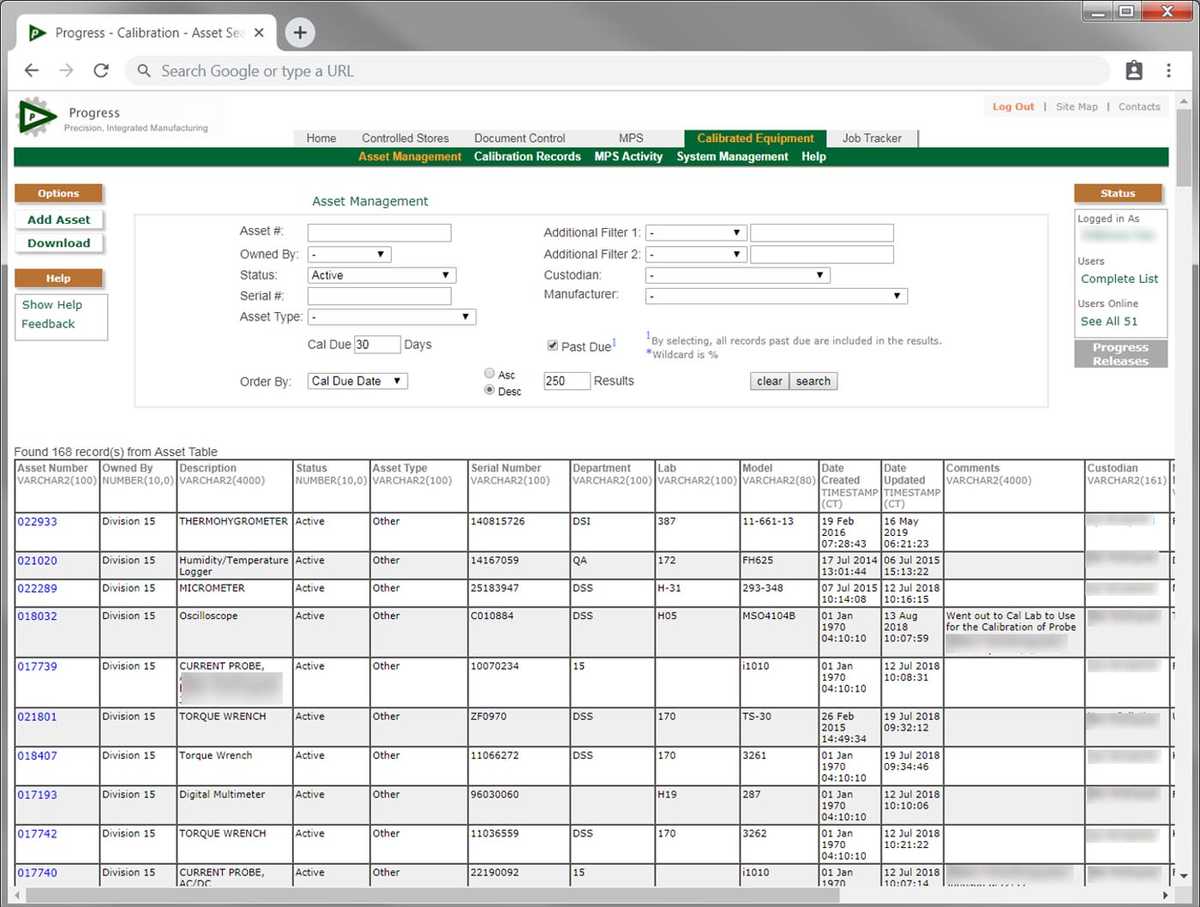

Calibrated Equipment

Create and manage calibrated equipment assets and associated calibration records. Integrates with the MPS and stock management modules so calibrated equipment is linked to manufacturing and QA receiving activities.

Job Tracker

Track and manage requests for special manufacturing related jobs, link. Additional functions include linking to the MPS module, linking resources to jobs for inventory and cost management and resource cost reports.

Or call Robert Thorpe at +1 210 522 2848.