Diesel engine designs continue to evolve to meet ever-changing emissions and fuel economy requirements. The technologies in newer engines, such as high exhaust gas recirculation (EGR), complex exhaust aftertreatment systems, improved combustion systems and higher peak cylinder pressures, place increased demands on crankcase lubricants. Lubricants and lubricant test procedures also continue to evolve to meet these demands.

We are one of the oldest and largest service providers for the evaluation of engine lubricants used in diesel engines for factory fill and service fill requirements. Facilities and staff are available to evaluate lubricants against the American Petroleum Institute (API) CH-4, CI-4, CI-4 PLUS, CJ-4, CK-4 and FA-4 as well as Cummins, Mack, and John Deere requirements. Evaluations are performed with respect to engine oil soot handling, oil oxidation, wear (camshaft lobes, camshaft followers, piston rings, piston liners, and connecting rod bearings), oil consumption, piston deposits, and fuel economy. New design engine components are also evaluated to determine acceptability with current day lubricants. In addition to engine based testing, we perform all related analytical bench tests required to qualify lubricants.

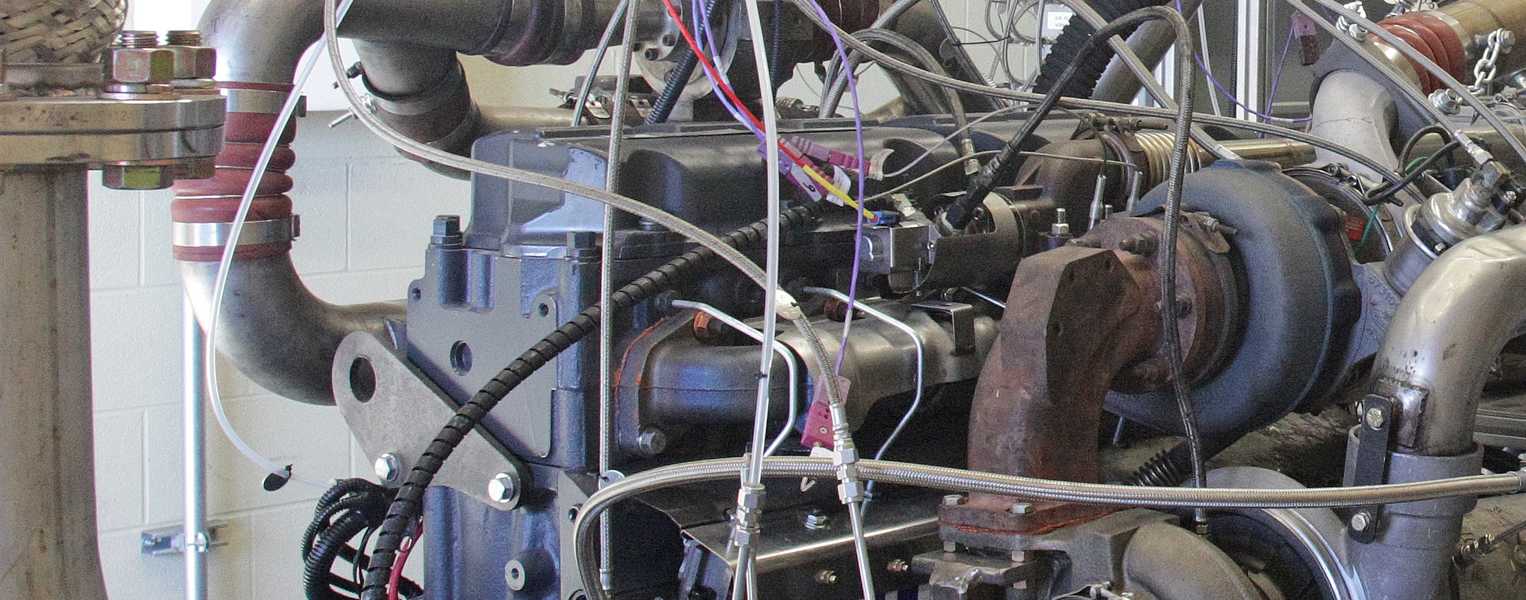

SwRI has over 43 test stands available for diesel lubricant test procedures, which utilize engines representative of heavy-duty diesel engines operating in modern commercial fleets and off-highway applications, including:

Caterpillar 1R Lubricant Test

The purpose of the Caterpillar 1-R 504-hour test is to evaluate the performance of crankcase lubricants with respect to piston deposits, ring sticking, ring and cylinder wear, piston, ring and liner scuffing, as well as lubricant consumption. This test is required for the CI-4 category and uses a calibrated 1Y3700 engine with 0.05 percent sulfur fuel.

Caterpillar 1K Lubricant Test

The Caterpillar 1K test evaluates the piston deposits, liner wear, and oil consumption associated with test lubricants using 0.4 percent sulfur fuel. Run on a Caterpillar 1Y540 single-cylinder direct injection engine, the procedure is steady state at 2,100 rpm and 8,000 BTU per minute fuel rate for 252 hours. This test is required by CI-4, CH-4 and MIL-L-2104F.

Caterpillar 1M-PC Lubricant Test

The Caterpillar 1M-PC 120-hour lubricant test is conducted on a 1Y73 indirect injection single-cylinder engine at 1,800 rpm and 42 hp. The test evaluates piston deposits, ring sticking, ring and cylinder liner wear, and piston, ring, and liner scuffing.

Caterpillar 1N Lubricant Test

The Caterpillar 1N 252-hour lubricant test is conducted on a calibrated 1Y540 engine, exactly like the 1K test except 0.05 percent sulfur fuel is used. This test is required for the CJ-4 category.

Caterpillar 1P Lubricant Test

The Caterpillar 1P test evaluates piston deposits, ring sticking, ring and cylinder liner wear, and piston, ring and liner scuffing, as well as lubricant consumption. The test is required for the CH-4 API category. This 360-hour lubricant test is conducted on a calibrated 1Y3700 single-cylinder overhead cam, electronically-controlled, direct injection engine using 0.05 percent sulfur fuel and a two-piece piston with a steel crown and aluminum skirt.

Caterpillar C13 Lubricant Test

The Caterpillar C13 is a 500-hour test uses a Caterpillar C13 engine with all steel pistons operated at 1,800 rpm and 1,200 grams per minute fuel rate to evaluate the performance of crankcase lubricants with regard to piston deposits and lubricant consumption. The test is required for the CJ-4 category.

Cummins ISB Lubricant Test

The Cummins ISB 350-hour test uses a Cummins ISB engine and is used to evaluate a crankcase lubricant’s ability to reduce camshaft lobe and sliding cam follower wear. After an initial 100 hours of steady state operation at 1,600 rpm to accumulate 3.25 percent soot in the oil, the engine is operated for 250 hours on a 28-second cycle simulating front-end loader operation. This test is required for CJ-4 qualifications.

Cummins ISM Lubricant Test

The Cummins ISM 200-hour test uses a Cummins ISM engine and is intended as a replacement test for the M11 EGR, using newer hardware. The engine has variable geometry turbo-charging, production EGR coolers and EGR valve. It evaluates a lubricant’s effectiveness at reducing soot related overhead wear, sludge and filter plugging. This test is required for CJ-4, as well as being an alternative to the M-11 EGR for the CI-4 category.

Engine Oil Aeration Test (EOAT)

The EOAT (Engine Oil Aeration Test) 20-hour test, using an International truck, 7.3-liter engine running at 3,000 rpm and wide-open throttle, evaluates an engine lubricant’s resistance to aeration. This test is required for CH-4, CI-4, and CJ-4 qualifications.

Caterpillar Oil Aeration Test (COAT)

The COAT (Caterpillar Oil Aeration Test) 50-hour engine test evaluates aeration performance of a lubricant when run on a Caterpillar C13 engine at high idle conditions. The aeration is calculated throughout the test by using continuously measured lubricant density. This test is intended to replace the EOAT and to be required for PC-11 qualifications.

DD13 Scuffing Test

The Detroit Diesel DD13 Engine Scuffing Test or the Daimler OM471LA engine test is a 200 hour evaluation of the lubricants ability to resist or protect against adhesive wear between an uncoated piston ring and cylinder liner. Testing is performed on a DD13 engine at 1800 RPM and torque of ~800 and ~1800 Nm respectively for stage one and stage two conditions until scuffing occurs or 200 hours is reached, whichever occurs first.

DD13 Fuel Economy Test

SwRI developed a Detroit Diesel DD13 Fuel Economy Test using the DD13 engine platform for the specific purpose of evaluating benefits derived from lubricants. The EPA Supplemental Emissions Test method was used as a basis for this testing with a number of lubricant test best practices applied.

Roller Follower Wear Test (RFWT)

The GM RFWT high-soot engine test is used to evaluate how well test lubricants limit axle wear in the roller cam lifter. For the test, a 6.5-liter, eight-cylinder, naturally aspirated, indirect-injection diesel engine is operated at 1,000 rpm with a high load for 50 hours. The test is required for CH-4, CI-4, and CJ-4 qualifications.

Detergency Test Procedure JASO M336

The JASO M336 Standard specifies the test method for evaluating the detergency of automotive diesel engine oils under high temperature and high load.

Valvetrain Wear Test Procedure JASO M354:2015

The JASO M354 Standard specifies the test method for evaluating wear of a cam and bucket lifter under high temperatures and load in a HINO N04C engine.

Fuel Economy Test JASO M362

The JASO M362 Standard evaluates the net change in fuel economy between a standard test oil and a fully formulated heavy-duty diesel oil to meet the new JASO DH-2F fuel economy oil category

Mack T8/T8A/T8E Lubricant Test

Test lubricants are evaluated for their ability to minimize viscosity increase and oil filter plugging associated with soot loading. The Mack T-8 test, required for API classifications CH-4, CI-4, and Mack EOL/M specifications, uses a 1991 in-line, six-cylinder, Mack E7-350, turbocharged, charge air-cooled, direct-injection diesel engine at 1,800 rpm. The engine is operated at rated load for 250 hours for the T8, 150 hours for the T8A, and 300 hours for the T8E.

Mack T11 Lubricant Test

The Mack T-11 252-hour test uses a Mack prototype E-Tech engine operating at 1,800 rpm with non-condensing cooled EGR and production 2002 heads, injectors and pistons, to evaluate a lubricant’s ability to limit viscosity increase with high soot loading. This test is part of Mack engine lubricant specifications EON+ 03, CI-4+ and CJ-4.

Mack T12 Lubricant Test

The Mack T-12 300-hour test uses much the same hardware as the T10 test, but now has a variable geometry turbocharger and production EGR cooling heat exchangers. To simulate 2007 engine operation, EGR rates are increased significantly from the T10 levels. Test objectives are the same; to minimize cylinder liner, ring and bearing wear. This test is required for the CJ-4 category.

Mack T13 Lubricant Test

The Mack T-13 is a 360-hour evaluation of the lubricants ability to resist oxidation and viscosity increases not due to soot loading. The goal is to provide extended drain intervals in modern engine technology. Testing is performed in a Mack MP8 engine at 1500 RPM and 2200 Nm of torque. Elevated lubricant, coolant, and EGR temperatures drive the severity of the test. It is a new test for PC-11.