The need for carbon dioxide pipelines and their associated compression equipment continues to grow as they are a critical component of carbon capture and storage (CCS) systems and enhanced oil recovery operations. Developing or converting pipelines for efficient transportation of CO2 poses unique challenges that Southwest Research Institute is well equipped to help solve.

CO2 Pipeline Analysis & Testing Services

SwRI’s Machinery Department, internationally known for its expertise in machinery and associated piping systems, is developing a variety of decarbonization solutions for industry and government. Our expertise includes carbon capture, carbon dioxide pipeline technologies, supercritical CO2 (sCO2) power systems, hydrogen energy research and more.

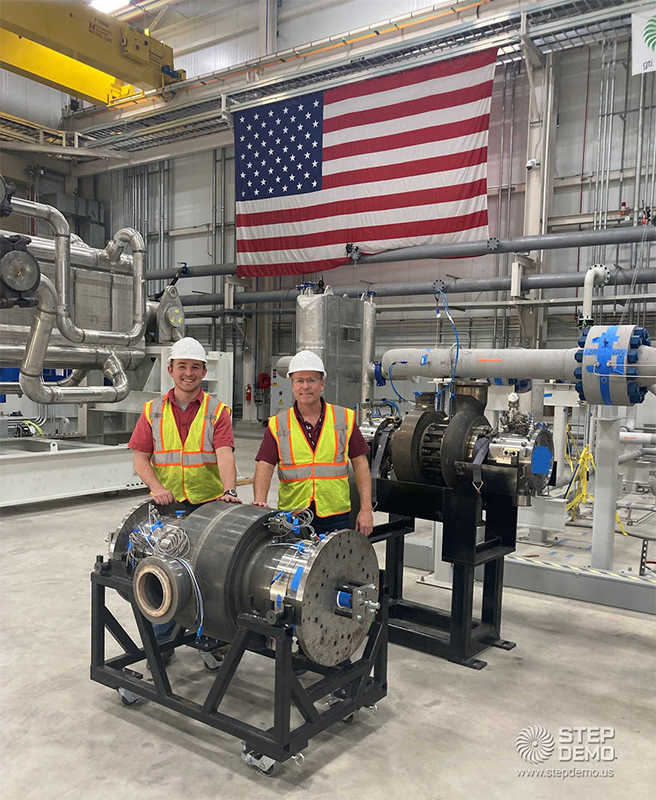

The Supercritical Transformational Electric Power (STEP) Demo pilot plant, 10-megawatt supercritical carbon dioxide (sCO2) test facility at SwRI, began operating with CO2 at supercritical fluid conditions.

Pulsation Analysis

- Centrifugal Compressors: Testing validated vortex-shedding (Strouhal/FIP)

- Reciprocating Compressors: API 618 analysis, Pulsation Bottle Design

Thermal Stress Analysis

- Evaluation of pipe stress due to large temperature gradients from mixing or phase changes

- Experience with multi-stage piping with unique components

System Dynamic (transient hydraulic/surge) Analysis

- SwRI has experience modeling CO2 systems

- Experience with unique properties of CO2

Conversion of Natural Gas Pipelines to CO2 Transport

- Define operating conditions for CO2 conversion to avoid phase change issues

- Control of thermal effects and manage liquid dropout or separation from pressure drops, blowdown, pipeline fill, transients

- Evaluate equipment and piping components for compatibility

Supercritical CO2 Tech wins R&D 100 Award

Compander advances non-hydrocarbon power with 10 MW concentrated solar power (CSP) supercritical carbon dioxide (sCO2) plant.

Press ReleaseOther CO2 Testing Services

SwRI currently operates both a CO2 compressor and CO2 pump loop over a wide range of conditions with CO2 in all phases (gas, dense, liquid) as well as a supercritical CO2 power cycle test facility. These test facilities can test the performance and operation of various piping and instrumentation components. We also perform thermophysical property testing of pure CO2 and CO2 mixtures (flue gas, impurities, etc.)