There is a continuously growing industry and government interest in blending hydrogen into existing natural gas pipeline systems to utilize existing infrastructure for hydrogen storage and transportation. The hydrogen, produced from rapidly expanding renewable energy sources, will help to enable decarbonization and energy storage.

However, before blending hydrogen into existing natural gas pipelines, a number of potential issues need to be considered, such as material compatibility, gas properties, compressor performance and pulsation control, sizing of auxiliary equipment, blowdown and pressure protection systems, gas metering, and safety impacts on ventilation, stratification, instrumentation and electrical systems.

Analysis & Testing Services

A reciprocating compressor flow loop tests hydrogen blending with natural gas at pipeline pressures, temperatures and horsepower levels.

Southwest Research Institute can offer the following analyses when evaluating a natural gas compressor station for hydrogen blending with natural gas:

Pulsation Analysis

- Centrifugal compressors – vortex-shedding (Strouhal) excitation.

- Reciprocating compressors – orifice plate sizing and pulsation bottle design.

System Dynamic (Surge) Analysis – Coastdown curves will change and mass flow through the surge control valve may decrease. The surge control system should be re-evaluated.

Blowdown System Capacity – Mass flow capacity through pressure regulators (valves and orifice plates) can decrease with increasing hydrogen content. The over-pressure protection system should be re-evaluated.

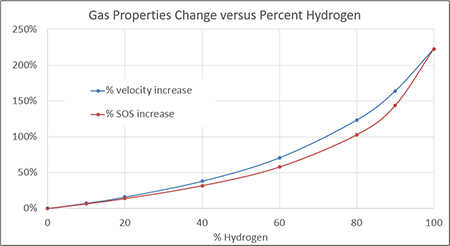

Natural gas properties (flow velocity and speed of sound) change as more hydrogen is blended into the natural gas.

Other Hydrogen Blending Tests

- Thermophysical property measurement of hydrogen blended with gas mixtures.

- SwRI is in the process of upgrading an existing 4-stage Ariel JGT/4 reciprocating compressor flow loop at our San Antonio, Texas, facility to accommodate experimental testing with hydrogen and natural gas blends to evaluate performance, pulsation and vibration, instrumentation, blending and separation technology, flow measurement and leakage. The flow loop upgrade is planned for completion in 2024.

For more information, contact Sarah Simons or call +1 210 522 2418.

Flow Component Testing

Our Flow Component Testing Facilities (FCTF) expanded safety and performance testing capabilities for hydrogen valve testing, leak detection and other H2 blended natural gas pipeline applications.