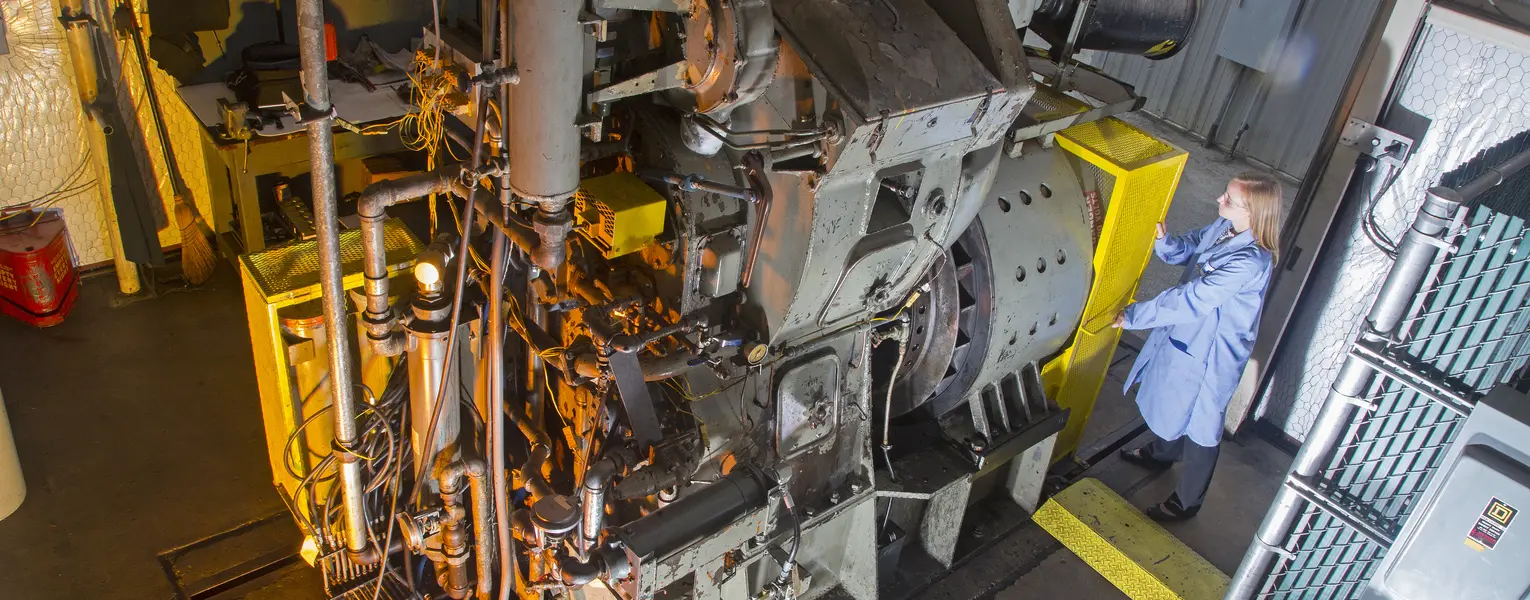

To help clients determine whether their lubricating oil qualifies for use in locomotive engines, Southwest Research Institute (SwRI) uses a General Motors Corporation Electro-Motive Division (EMD) 2-567C two-cylinder research engine to conduct a 25-hour Silver Lubricity Test.

With a type D-1 assembly, the test stand is built up using new piston pins and special pin bearings, which are measured and weighed before and after the test. The engine lubrication system is flushed with test oil and the crankcase is charged with new oil prior to running a 9-hour, 20-minute, EMD-type break-in.

Bearing conditions are intentionally sensitized by using special non-production wrist pin bearings. No lead overlay is used on the pin bearings to protect the silver surface, and no center oiling hole or oil slot is utilized by the test bearings. As a result, the as-manufactured surface of the hardened steel wrist pin is presented directly to the clean, finished silver surface of the bearing without the seating benefits afforded by the lead overlay.

Test oil is applied to pins and bearings before assembly and the engine is pre-lubed with test oil before starting. The engine sump holds 45 gallons, with 85 gallons of test oil required for each test. One-quart samples are taken of new test oil after break-in and at end of test. These three samples are kept for six months and are available to the client. After running the 25-hour Silver Lubricity Test, the special pin bearings are rated using the EMD distress demerit procedure to determine whether the oil meets the criteria set by EMD to qualify for locomotive use.

EMD Silver Lubricity Test

Primary Test Operating Conditions

| Engine Speed Fuel Flow Airbox Pressure Oil Inlet Temp Coolant Inlet Temp |

835 ± 2 rpm 91.0 ± 1.0 lb/hr 6.8 ± 0.1 inch Hg 210°F ± 2°F 180°F ± 2°F |

| Fuel Type | 0.1% nominal sulfur, 47 to 50 cetane, #2 diesel |

| Piston Pin Bearing Distress Limit |

40 demerits, max |