Since the turn of the last century, steam turbine generators have earned an enviable reputation for economy and reliability in converting heat energy to electrical energy under the most exacting service conditions. Southwest Research Institute (SwRI) provides expertise and extensive laboratory facilities to meet the challenges imposed in the design, assembly, and reliable operation of turbines of all sizes.

Capabilities

Remaining Life Assessment

Critical turbine components must be evaluated to assure safe operation during their lifetime. Accurate life assessment procedures, coupled with a knowledge of specific rotor material properties, prevent costly premature retirement of rotors.

A wide range of finite element programs is used at SwRI to perform structural evaluations and remaining life assessment, including:

- ANSYS®: Structural analysis

- NASTRAN®: Structural analysis

- STRAP/SAFER: EPRI rotor integrity and life analysis

- BIGIF: EPRI fracture mechanics

- ADINA/ADINA-T: Structural/thermal analysis

- ABAQUS: Nonlinear structural analysis

- NESSUS®: Probabilistic structural analysis

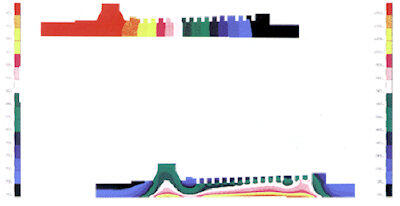

The SAFER code calculates steady state temperature (oF) contours for a high pressure (HP) rotor (top). Steady state stress contours (psi) for an HP rotor are determined using the SAFER finite element code (bottom).

Low pressure (LP) steam turbine disc cracking caused by stress corrosion is experienced worldwide in rotors used in both nuclear and fossil fuel power plants. Cracking occurs in LP rotor discs in keyways, in the blade attachment areas of the rims, on bore surfaces, and on web surfaces. Under a cooperative industry research project, funded by a consortium of electric utilities, SwRI has developed the technology required to make remaining life predictions for shrunk-on low pressure turbine discs. Heat transfer analysis and stress analysis determine shrink-fit stresses, thermal stresses, and stress due to blade and disc mass. Disc integrity and remaining life assessment are conducted and recommendations are provided to help determine run, replacement, or reinspection intervals.

Superheated Steam Machinery Testing

SwRI has a Clayton E304 Steam Generator with Super Economizer, which gives it the capacity to test superheated steam machinery at a variety of pressures. Our generator has the following capabilities:

- 10,500 lbs/hr. Steam

- 10,042,500 BTU Net Heat Output

- Operating pressure from 15-350 psig

- Delivered steam temperature up to 300°C

- Efficiency > 85%

To maximize and maintain steam purity, we use reverse osmosis treated water in our steam generator.

Nondestructive Evaluation

The SwRI turbine rotor examination/evaluation system (TREES) possesses unique examination capabilities and excellent flaw resolution achieved by computer-designed focusing lenses attached to ultrasonic transducers. Six lens configurations are employed to examine zones within the rotor with beam diameter sizes from 0.031 to 0.125 inch.

SwRI offers numerous nondestructive evaluation techniques for inspection of turbine rotors, disc steeples, and keyways, including periphery ultrasonic, dye penetrant, magnetic particle, and eddy current inspection services.

SwRI developed the turbine rotor examination/evaluation system (TREES), an automated rotor bore ultrasonic examination system for steam turbines that incorporates features such as focused search units and a volumetric cell structure to produce unique examination capabilities and excellent flaw resolution. Focused beam search units provide a reliable means of detecting and sizing flaws without using conventional signal amplitude techniques. An automated data acquisition and processing computer system processes the data. SwRI can custom assemble the TREES package and provide boresonic inspection services.

SwRI has extensive laboratory and field experience in developing and implementing internationally recognized inspection and evaluation procedures. Under a utility consortium program, an ultrasonic disc rim inspection system was developed that detects and sizes cracks in blade attachment areas without blade removal.

SwRI also conducts hardness measurements, replication, and microstructural assessments in the field using portable equipment.

Failure Analysis & Prevention

SwRI uses a multidisciplinary approach to metallurgical failure analysis on a wide range of steam turbine and boiler components. Metallurgy, corrosion, stress analysis, fracture mechanics, and nondestructive evaluation are combined to identify mechanisms and root causes of failure. Such analyses help predict and monitor remaining component life.

SwRI maintains a certified hot laboratory for handling materials contaminated by radiation.

Materials Testing & Evaluation

Static strength, creep, fatigue, impact, fracture toughness, crack growth rate, macro- and micro-hardness, and other testing and evaluation techniques are available in SwRI's extensive laboratories.

Controlled test environments include temperature, humidity, vacuum, high pressure, and immersion in chemically controlled gaseous or aqueous media. Specialized test capabilities include controlled multi-axial stress conditions, strain rates continuously variable from 10-6 to 10-4 s-1, coupled thermal and mechanical testing, programmed spectrum loading, and direct uniaxial loading to 1,650°C (3,000°F).

Sophisticated computer-controlled servo-hydraulic test systems are available, and many physical and thermal-physical property measurements are made according to ASTM standards. Specialized test equipment can be designed and assembled to meet unique test requirements.

Vibration Problem Diagnosis

Using advanced techniques for field measurement, signal processing, diagnostic analysis, and other predictive tools, SwRI can identify and solve rotor, blade, and structural dynamics problems that put steam turbine generators out of commission. These techniques are used to solve field problems, while providing confidence at the design stage that turbine trains will exhibit low vibration levels.

- Laboratory analysis of vibrational problems with rotating machinery and piping

- Steam turbine-generator rotor balancing

- Custom design of instrumentation and components for special applications

- Component testing of valves, pumps, pressure vessels, and instruments

Other capabilities include:

- Materials degradation studies

- Structural integrity analysis

- Telemetry testing

- Field hardness testing and replication

To contract with SwRI, please contact the Machinery Services Hotline at +1 210 522 3000.

For more information, contact Ben White or call +1 210 522 2554.