DETAIL

The Department of Energy modeled the Advanced Research Projects Agency–Energy (ARPA–E) after the Department of Defense’s Defense Advanced Research Projects Agency (DARPA). ARPA–E’s NEXTCAR Program is short for “NEXT-Generation Energy Technologies for Connected and Automated On-Road Vehicles.” ARPA–E funds emerging high-potential, high-impact energy technology projects to prepare for commercial investment.

While the transportation sector is the single largest source of greenhouse gases in the U.S., the fundamental efficiency of today’s vehicles is quite high, offering significantly reduced emissions. Since model year 2004, CO2 emissions have decreased by 25% and fuel economy has increased by 32%. These advances make it incredibly difficult to achieve significant progress using conventional vehicle efficiency improvements. Incrementally modifying components and control systems typically ekes out 1–2% improvements at costs often in the millions of dollars.

However, recent rapid advances in driver assistance technologies and vehicles with increased levels of connectivity and automation have created opportunities to improve the efficiency of future vehicle fleets in radically new ways. The initial ARPA–E’s NEXTCAR Program had an ambitious target: To create enabling technology to reduce the energy consumption of a plug-in hybrid electric vehicle (PHEV) by an astounding 20% without changing the powertrain or compromising emissions, safety or drivability.

In 2017, a Southwest Research Institute-led team received a three-year contract from the Department of Energy to develop model-predictive control for energy-efficient maneuvering of connected and automated vehicles. The project’s goal was to provide control algorithms leveraging vehicle-to-vehicle (V2V), vehicle-to-infrastructure (V2I) and vehicle-to-everything (V2X) technologies to simultaneously optimize the route, speed profile and power flows of a hybrid vehicle. The project sought to define future powertrain performance requirements and enable more efficient control of the powertrain and vehicle dynamics.

ABOUT THE AUTHORS

From left, Sankar Rengarajan, manager of the Powertrain Engineering Division’s Model-Based Control Section, specializes in dynamic systems and controls, particularly in energy efficiency and emission control applications. Michael Brown, an Institute engineer in SwRI’s Intelligent Systems Division, has served various federal, state and commercial clients in projects ranging from advanced traffic management and traveler information systems to connected and automated vehicles and smart cities. Scott Hotz, director of the Powertrain Engineering Division’s Control Systems Department, specializes in custom solutions through model-based control algorithms, embedded systems and electronics.

Phase II of SwRI’s ARPA–E NEXTCAR project seeks to increase energy savings to greater than 30% using Level 4 automation technologies, such as lidar and SwRI’s patented Ranger localization technology.

Eco-Driving

SwRI was particularly well positioned to conduct the program, with multidisciplinary expertise in vehicle powertrain development and connected and automated vehicle technologies. For most of SwRI’s 75 years, automotive engineers have designed, developed and analyzed components, transmissions, engines and vehicles for efficiency and performance. Specialists also support research and modeling for fuel mixing, combustion, filtration and fluid flow analysis. As a pioneer in measuring vehicle exhaust emissions, the Institute continues to raise the bar with new methodologies of characterizing engine exhaust constituents.

SwRI also has over 25 years of experience developing and deploying advanced intelligent transportation and traffic management technologies to create safer, more coordinated and more efficient transportation networks. These smart technologies include a range of connected and automated vehicle applications that are now being applied to efficiency efforts.

SwRI’s NEXTCAR team developed and integrated components to assist in eco-driving — avoiding unnecessary stopping and minimizing acceleration that wastes energy — as well as instituting preferred routes and optimal vehicle speed profiles. Given this connected “look-ahead” preview of conditions, engineers also optimized powertrain operation in pursuit of a 20% improvement in energy economy.

Onboard sensing combined with data from V2V, V2I and V2X technologies provided the information needed to predict driving environments and develop new technologies and algorithms. Vehicle connectivity and automation were already improving vehicle safety and driver convenience. For this program, the team tapped into those existing data streams and put the information to use to improve vehicle efficiency. The team integrated these tools to develop next-generation vehicle dynamics and powertrain control software, designed to proactively use “look-ahead” information to anticipate vehicle power demand.

SwRI-developed tools use roadway connectivity data to find the most eco-friendly route to a destination. While the average driver will save fuel by using these routes, heavy-duty truck fleets will realize the greatest energy savings.

SwRI developed an eco-mobility app that uses roadway connectivity data to advise drivers to speed up or slow down to avoid red lights. Significantly more energy is required to accelerate vehicles, particularly heavy-duty trucks, after making a full stop at lights.

Eco-Tools

The new tools developed to meet these efficiency goals include eco-routing, eco-driving and power-split optimization.

DETAIL

Smart traffic lights improve intersection safety and efficiency, using data from sensors, cameras, GPS, vehicles, cell phones and other devices to detect traffic patterns and volume as well as pedestrians and bicyclists approaching an intersection.

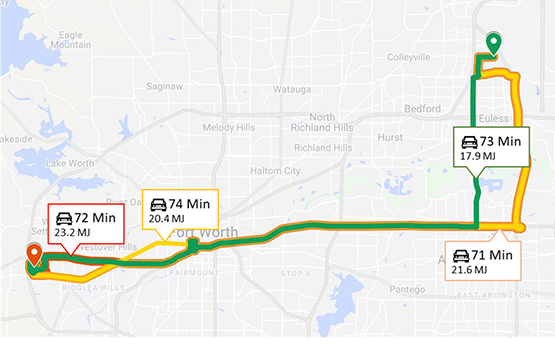

SwRI refers to its eco-routing tool in development as “Google® Maps with energy.” Using a mapping tool like Google Maps, drivers can set their destinations and see routes that may add a couple of minutes to their arrival but are more fuel-efficient. While the technology is appealing to the eco-minded consumer, for delivery and service fleets, this 5–10% savings in fuel consumption can add up to millions of dollars in savings each year while cutting carbon emissions.

Located in SwRI’s Ann Arbor, Michigan facility, SwRI’s connected and automated vehicle chassis dynamometer runs a vehicle in response to traffic data. A data acquisition system collects relevant operating data to determine the efficiency improvements.

Eco-driving uses information from neighboring vehicles to minimize braking and accelerations.

Hybrid-electric vehicles need an energy management system optimized to ensure good fuel economy while maintaining battery state-of-charge, controlling the power split between the engine and the electrical motor. Optimal power split scenarios depend on the driving cycle, initial state-of-charge and trip length. SwRI’s power-split optimization tool uses knowledge of routes and speeds to optimize battery and engine operations to efficiently meet power demands.

SwRI engineers used internal funding to deploy the eco-driving technology in a mobile driver advisory application that runs on regular smart phones or tablets. The driver advisory app connects with traffic lights and roadway infrastructure to “see” up to half a kilometer ahead and alert drivers to drive more efficiently. For example, if the app senses a traffic light ahead, it will advise the driver to speed up or slow down by a few miles per hour to avoid stopping. For heavy-duty trucks, making a full stop at a red light and re-engaging the engine when the light turns green is a significant source of fuel consumption.

DETAIL

A dynamometer or “dyno” is a laboratory test fixture that creates a load to duplicate various speed and torque requirements. The resulting data is used to calculate power.

These app-based tools can be used in any on-road vehicle. Based on their success, the SwRI team collaborated with regulatory and commercial organizations, working to commercialize the new tools.

Separately, the U.S. Department of Energy funded a project to investigate the benefits of using connected and automated vehicle (CAV) technology with different types of vehicles, as well as evaluating the impact of smart infrastructure solutions like intelligent intersections as part of the Energy Efficient Mobility Systems initiative.

SwRI’s connected and automated vehicle chassis dynamometer uses traffic simulation software to evaluate eco-mobility tools.

To support these developments, the team built a connected and automated vehicle chassis dynamometer to measure speed and torque to understand power. The dyno uses traffic simulation software to provide a controllable, repeatable environment to test the new technologies. The team calibrated the software using real-world data to simulate various cities, including San Antonio, Fort Worth, and Columbus, Ohio. The simulations proved critical for evaluating control algorithms and accurately quantifying energy consumption. In 2021, SwRI received an R&D 100 award, recognizing its NEXTCAR work as one of the most significant innovations of the year by R&D Magazine.

The second phase of SwRI’s NEXTCAR project builds on the success of eco-routing, eco-driving and power-split optimization, expanding to explore cooperative control, smart lane change/ merge and dedicated connected and automated vehicle (CAV) operations.

Eco - ii

Based on the success of Phase I, achieving more than 20% efficiency improvement, SwRI was awarded a three-year follow-on contract in 2021. This phase continues development of SwRI’s cutting-edge connected and automated vehicle technologies to improve passenger vehicle efficiency and reduce carbon emissions, shooting for an increased 30% reduction in energy consumption. SwRI will integrate its technologies into a vehicle with Level 4 automation, which gives vehicles the ability to perform all driving operations on their own with optional human override.

In the second phase, SwRI is building on those technologies and expanding its predictive eco-routing, eco-driving and hybrid power control strategies. The eco-driving feature focused on longitudinal dynamics control and contributed about 10% of the energy savings. The algorithm helped the human driver make smarter decisions based on localized traffic knowledge through V2X connectivity and communication. The advanced perception and actuation precision of a Level 4 automated vehicle over a human driver allowed SwRI to expand the eco-driving framework to optimize for multilane dynamics and further reduce energy consumption.

The team discovered that the connected and advanced driving assistance systems that make cars safer and easier to drive can also make them much more efficient, using less power and saving drivers money at the pump. These technologies are a win-win for drivers and can lead to a cleaner transportation sector and rapid progress toward a carbon-free future.

Eco-Demonstration

SwRI conducted extensive testing of its NEXTCAR applications on its virtual-traffic-enabled test track, simulating real-world scenarios to evaluate technology performance.

As Phase II progressed, SwRI focused on infrastructure and simulation studies and demonstrated the technology using the CAV chassis dynamometer and specialized test tracks. SwRI’s technology suite, which is midway through its second development phase, has seen significant progress.

SwRI has made advancements in building a Level 4 autonomous vehicle, fusing widely adopted sensing technologies, such as lidar, with SwRI’s patented Ranger localization technology. This technology maintains vehicle position within 2 centimeters, in contrast to GPS measurements, which can vary by several meters. The automation stack integrates with SwRI’s drive-by-wire system, which uses electrical systems to replace mechanical braking and steering systems with minimal modifications to a vehicle.

Extensive testing on SwRI’s virtual-traffic-enabled test track simulated real-world scenarios to evaluate technology performance. Engineers also tested vehicles traveling together in a synchronized formation or “platoon,” validating computational fluid dynamics models for cooperative platoon formation. Through these tests, the team demonstrated how synchronized driving could optimize efficiency and how CAV technologies can help passenger vehicles operate more efficiently.

DETAIL

Lidar, an acronym for “laser imaging, detection and ranging,” determines distance, targeting an object or a surface with a laser and measuring the time for the reflected light to return to the receiver.

Currently, the SwRI team is seeking avenues to pilot the technology in real-world conditions and collaborating with fleet original equipment manufacturers and suppliers to help bring the technology to market. The “Eco-Mobility with Connected Powertrains” technology suite and the Phase II developments are available to license.

These technologies have the potential to revolutionize the transportation sector, reducing its carbon footprint through energy consumption and emissions reduction capabilities, while making roads safer and more efficient. By working together with industry, the SwRI team can make a significant contribution toward the development of sustainable transportation systems.

Questions about this story or Connected Powertrain? Contact Robert Coppersmith at +1 248 820 7844 or Michael Brown at +1 210 522 3104.