Electric power generates the second largest share of greenhouse gas emissions and includes emissions from electricity production used by end use sectors, such as industry. Nearly 80% of electricity in the U.S. comes from burning fossil fuels, mostly coal and natural gas.

Geothermal energy as a zero-carbon, sustainable and renewable energy source remains largely untapped. This environmentally friendly resource has the potential to meet heating, cooling and electricity demands for the future, but there are challenges to overcome to fully exploit this natural resource. Geothermal energy taps existing heat beneath the Earth’s surface to produce energy.

DETAIL

A lifecycle perspective accounts for all greenhouse gas emissions connected to a good or service, from production through service life and disposal.

Underground reservoirs of hot water or air are accessed by wells, ranging from a few feet to several miles deep, bringing steam and very hot water to the surface to generate energy or for direct use in heating and cooling systems. Geothermal energy is renewable, produced as naturally occurring radioactive elements decay, heating the Earth’s interior. Geothermal power plants produce electricity, running 24 hours per day, seven days per week, regardless of weather conditions, and they consume less water than conventional electric power plants. Harnessing geothermal power from domestic resources requires only a compact powerplant, which typically emits no greenhouse gases and generates a fraction of the lifecycle emissions associated with solar panels and natural gas.

Geothermal energy is a viable zerocarbon power source that could provide highly reliable baseload electricity on the path toward a decarbonized energy economy. A recent collaborative study analyzed the geothermal potential in Texas, concluding total geothermal resources are roughly a million times the state’s annual electricity generation. If the state drilled geothermal wells at its existing pace for oil and gas production wells, geothermal energy production could match the state’s total use of fossil fuel energy in just four years.1 Geothermal power shows promise for many locations beyond Texas as well. Recent advances in engineered, deep and closed-loop geothermal technologies have created opportunities for surface power generation to operate at higher temperatures with higher efficiencies. Southwest Research Institute is conducting research to develop and validate technologies for commercial deployment, including recent and ongoing efforts to develop supercritical carbon dioxide (sCO2) technology for geothermal energy.

ABOUT THE AUTHORS

The late Dr. Jordan Nielson was a group leader in the SwRI’s Rotating Machinery Section, providing design expertise, engineering support and project management oversight for sCO2 power generation systems, particularly in geothermal applications. Kelsi Katcher is a senior research engineer specializing in machinery and component design and testing activities, including high-pressure, high-temperature sCO2 power cycle applications. Research Engineer Dr. Owen Pryor designs and analyzes machinery and power cycles, developing energy storage, turbomachinery, combustion dynamics, alternative fuels and supercritical carbon dioxide technology. Dr. Tim Allision leads SwRI’s Machinery Department, designing, analyzing and troubleshooting advanced turbomachinery in a range of energy production applications.

Supercritical Carbon Dioxide

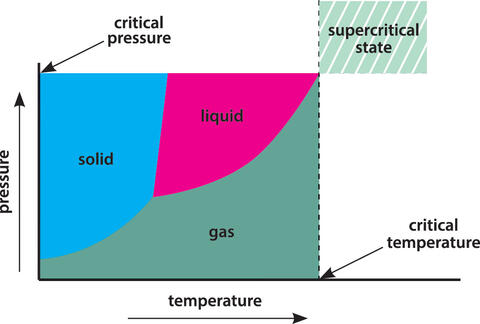

The supercritical temperature of a substance is the temperature where gases cannot become liquid, regardless of the applied pressure. (See related story.)

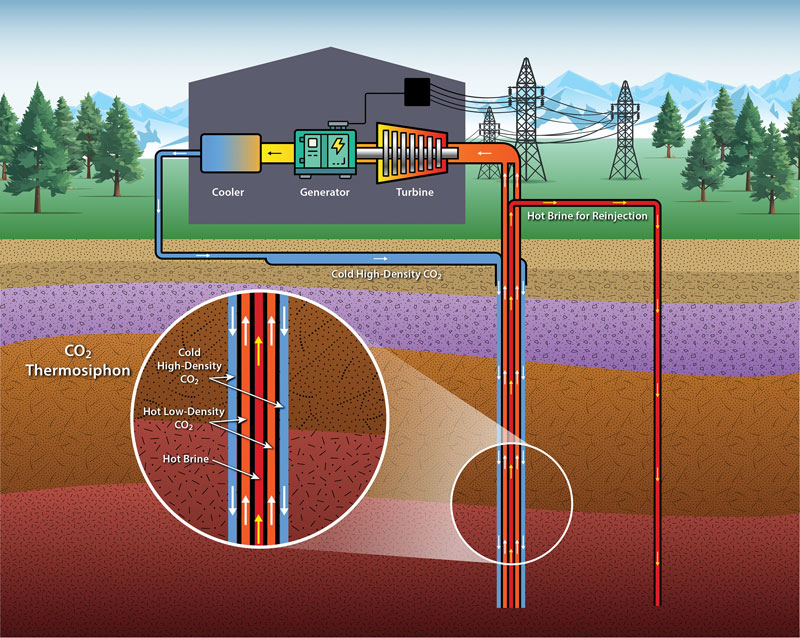

Supercritical CO2 is a fluid state of carbon dioxide, held at or above its critical temperature and critical pressure. Carbon dioxide has a critical temperature of 88 F (31.1 C), which is a relatively moderate temperature. At conditions near its critical pressure of 7.39 Megapascals (1,072 psi), CO2 experiences strong density changes with only a few degrees of temperature change. These fluid properties can be exploited to create a closed-loop thermosiphon, circulating sCO2 through a turbine generator with only thermal inputs. This passive heat-exchange-driven process does not require a pump or compressor, minimizing parasitic loads and increasing power cycle efficiency.

DETAIL

Technoeconomic modeling analyzes the economic performance of an industrial process, product or service, estimating capital and operating costs as well as potential revenue.

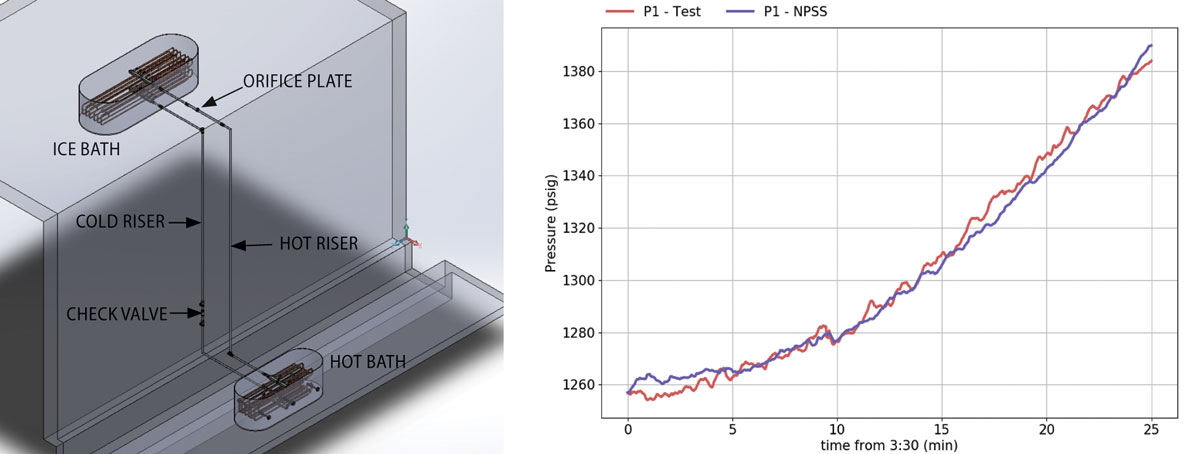

With internal research funding, SwRI validated transient and steady-state models for an sCO2 thermosiphon through a laboratory setup. The project applied these validated models to develop turbine designs, system sizing and technoeconomic models for various power generation applications, including data center and geothermal applications. The analysis found geothermal installations with large elevation changes (at least 2,300 meters) to be the most promising application of an sCO2 thermosiphon for power generation with a potential thermal conversion efficiency over 17%.

SwRI developed a lab-scale sCO2 natural convection test loop (left) to validate simulated pressure transients (right).

Optimization

A follow-on project used the model and datasets to analyze a commercial thermosiphon-based geothermal system developed by a commercial client. The model provided expected pressures, temperatures and flow rates for a 12 MWe sCO2 turbine at the surface. SwRI then used the data to investigate the powerplant capital costs for a geothermal system, including the turbine and required cooling equipment. The analysis showed that a radial turbine is well suited for sCO2 inlet conditions from 80-150 C. The analysis also showed that cooling the process fluid before reinjection in the geothermal well is the largest challenge for the techno economics of the power cycle, representing much larger costs than the sCO2 turbine. However, the cost of cooling is comparable to present-day geothermal power cycles while greatly reducing the cost of the power generation equipment.

This schematic of a geothermal thermosiphon illustrates its CO2 injection leg, CO2 production leg, surface equipment and brine reinjection leg configuration.

sCO2 Geothermal Applications

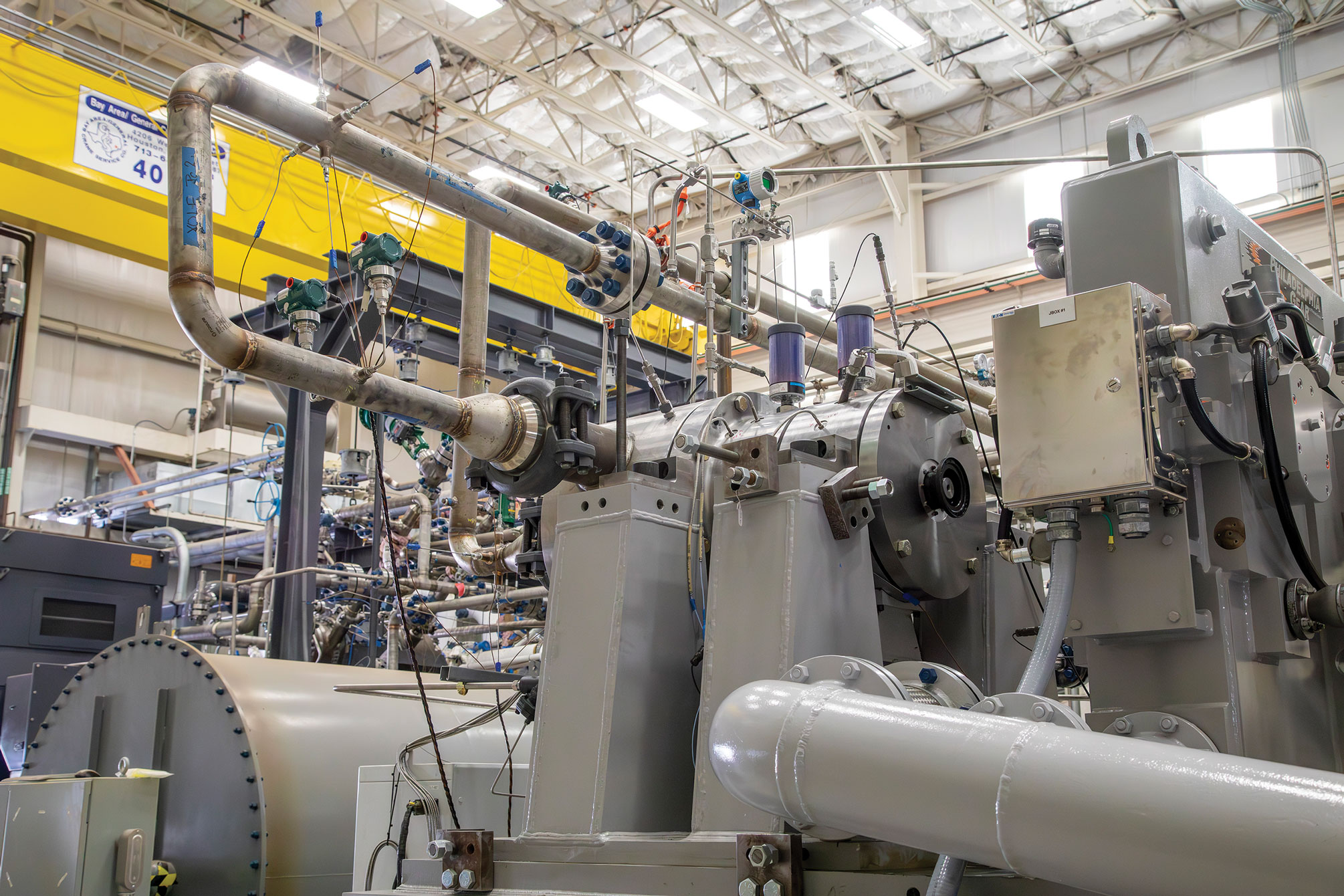

SwRI has developed a 3 MWe sCO2 turbine design for a commercial client to evaluate its geothermal system. The high-speed radial turbine is designed for a 347 F (175 C) inlet temperature and drives a generator through an approximately 10:1 speed-reducing gearbox. After the full-scale laboratory test, the turbine will be delivered to a field site for full system testing.

SwRI engineers developed a 3 MWe sCO2 turbine for geothermal applications and integrated the machinery into a production rig.

This article is dedicated to Dr. Jordan Nielson, who passed away unexpectedly in April 2023. Nielson led many of SwRI’s efforts developing geothermal power system technologies and was known for his strong work ethic and team leadership.

Decarbonizing Texas Oilfields

With internal funding, SwRI is collaborating with The University of Texas at Austin to identify favorable conditions for harnessing geothermal power in the Wilcox-Eagle Ford-Austin Chalk petroleum production region. The team will quantify the downhole conditions available in the petroleum play, and SwRI will build models to explore different power cycle options and examine the techno economics and technical feasibility of these power cycles for the application.

GEMS Workshop

SwRI will host a new Geothermal Energy Machinery and System (GEMS) Workshop this fall to provide an opportunity for experts in industry, academia and government to meet and discuss the technology development needs for advanced geothermal surface plants. As a joint industry-government-academia workshop, the GEMS open information and networking session aims to advance geothermal power plant technology, including direct (steam) flash, indirect organic Rankine, sCO2 and other power cycle machinery and systems needed to meet demands for advanced geothermal surface power technology. The workshop will bring researchers, industry partners and end users together to discuss state-of-the-art technology and application requirements. Participants will identify technology gaps to develop guidance to identify, coordinate and direct future pre-competitive research and development activities to advance geothermal power technologies.

As extreme weather events like heat waves as well as cold weather anomalies like Winter Storm Uri increase in frequency with a changing climate, geothermal energy could improve energy reliability and resilience, providing comfort and peace of mind for consumers. SwRI is investigating a range of new technologies to make the most of this underutilized secure, clean and ubiquitous resource.

Questions about this story or Renewable Energy? Contact Tim Allison at +1 210 522 3561.

[1] Beard, J.C. and Jones, B.A., “The Future of Geothermal in Texas: Contemporary Prospects and Perspectives,” Cynthia and George Mitchell Foundation, 2023.