Click below to jump to an article of interest.

Improving Military Fuel Tests

Engineers in SwRI’s Fuels and Lubricants Division are working to improve fuel lubricity laboratory bench tests to accelerate fuel qualification and lower costs. Standard ASTM lubricity tests for diesel and aviation fuels had numerous issues and often gave vague, inconclusive results. The SwRI team is developing new laboratory bench methods that could save the industry significant time and money qualifying lubricating fuels.

“Both ASTM D6079 and D5001 were developed to address advances in fuel system hardware,” said Lead Engineer Gregory Hansen. “The increased capability and complexity of the systems required fuels with increased lubricating characteristics. Some of these lubricity requirements are satisfied with additives while others required more robust hardware.”

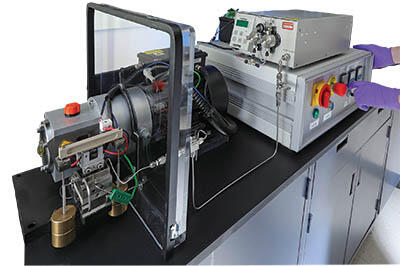

A new bench test uses small test specimens to characterize the lubricating properties of diesel fuels used in military vehicles.

SwRI has developed a new laboratory instrument that more accurately assesses the lubricity of diesel fuels, contributing to a more timely, cost-effective qualification process.

The tests are commonly required for fuels used by military vehicles and aircraft. Both tests use small specimens to test the fuels on a laboratory bench rig. These screening tests are quite good at detecting large changes in fuel composition, however, D6079 is particularly insensitive to small amounts of additive.

“At times, we could run one of these tests and the results would show no difference between a fuel with no additives and fuels with the maximum amount of additives,” Hansen said. “But there was no bench-scale alternative. Until now.”

Laboratory tests require a fuel sample of about 50 mL and last one to two hours. In contrast, more accurate full-scale fuel pump tests involve running fuel through an engine rig for thousands of hours, usually at least 40 continuous days. This requires roughly 1,000 gallons of fuel and staff supervision around the clock.

“A full-scale pump test is by nature more expensive and time-consuming,” Hansen said. “They replicate the actual engine operation with complete fuel system hardware and can take months to complete a single test.”

Beginning in 2016, Hansen began tweaking the standard laboratory tests, altering the conditions and the specimen geometries to see if he could improve correlations with the full-scale pump tests and improve confidence in laboratory efforts.

“We had some pretty encouraging results almost right away,” he said. “Full-scale pump testing will not disappear as hardware, fuels and additives continue to evolve. But lowering the amount of pump testing required can accelerate project timelines and save money.”

In 2018, Hansen began collaborating with the military on a custom bench instrument for the new, modified fuel tests. That device is now completed, and Hansen and his team are gathering data and preparing for the long process of introducing these new tests to the industry.

“These tests are very much new and improved,” he said. “Because the tests are initially focused on diesel-powered ground vehicles for the military, the process would be to write an official military standard that would be adopted into a performance specification for certain types of fuel purchases. Once the industry has experience supporting the new testing methods, the standard would be introduced as a new ASTM method for the commercial market.”

Small Satellite Missions Move Forward

PUNCH Mission Achieves Milestone

The Polarimeter to UNify the Corona and Heliosphere (PUNCH) mission achieved an important milestone, passing NASA’s critical System Requirements Review/Mission Definition Review (SRR/MDR). SwRI is leading PUNCH, a NASA Small Explorer (SMEX) mission that will integrate understanding of the Sun’s corona, the outer atmosphere visible during eclipses, with the tenuous “solar wind” filling the solar system.

“For over 50 years, we’ve studied the solar corona by remote imaging and the solar wind by direct sampling,” said PUNCH Principal Investigator Dr. Craig DeForest of SwRI’s Space Science and Engineering Division. “PUNCH will bridge that gap by imaging the solar wind itself as it leaves the outermost reaches of the Sun’s corona.”

The solar wind, a supersonic stream of charged particles emitted by the Sun, fills the heliosphere, the bubble-like region of space encompassing our solar system. Its boundary, where the interstellar medium and solar wind pressures balance, ends the sphere of the Sun’s influence.

Courtesy of NASA/JPLW

PUNCH is a constellation of four separate suitcase-sized satellites scheduled to launch in 2023 into a polar orbit formation. One satellite carries a coronagraph, the Narrow Field Imager, that images the Sun’s corona continuously. The other three each carry SwRI-developed wide-angle cameras, Wide Field Imagers (WFI), optimized to image the solar wind. These four instruments work together to form a single field of view spanning 90 degrees of the sky, centered on the Sun.

“Preparing for the SRR/MDR review was an unexpected challenge,” DeForest said. “Team members had been working at home, yet they met the challenge and presented their design in written and oral presentations culminating in the positive decision from our review board.”

SRR/MDR is a major milestone of mission development. It checks the flow of engineering and mission definition as activities segue into the design phase.

“I’m very proud of this team for what they’ve accomplished during less than ideal collaboration conditions,” said DeForest. “While spacecraft are constructed out of aluminum and exotic metals, they are initially made of requirements documents.”

TRACERS Heliophysics Mission Enters Phase B

NASA has approved the Tandem Reconnection and Cusp Electrodynamics Reconnaissance Satellites (TRACERS) mission to proceed to Phase B, which marks the transition from concept study to preliminary flight design. The satellites, led by the University of Iowa (UI) and managed by SwRI, are set to launch in late 2023.

In addition to providing mission management and science services to UI, SwRI is developing the Analyzer for Cusp Ions (ACI) instrument, which will study how the magnetic fields of the Sun and the Earth interact through novel measurements in the polar cusps. Under a subcontract to Millennium Space Systems, SwRI is also managing the development of its two satellite bus platforms, supporting instrument integration and testing, and conducting mission operations.

TRACERS will use two satellites to observe particles and fields at the Earth’s northern magnetic cusp region — the region encircling the Earth’s poles where our planet’s magnetic field lines curve down toward Earth. Here, the magnetic field allows particles from the boundary between Earth’s magnetic field and interplanetary space to access the atmosphere.

“TRACERS is an exciting mission,” said SwRI’s Dr. Stephen Fuselier, the mission deputy principal investigator and leader of the development of the ACI instrument. “We had the opportunity to do a test run of the mission and ACI when we flew NASA’s TRICE-2 rockets in the cusp in 2018. The data returned from that single pass through the cusp were amazing. We can’t wait to get the data from thousands of cusp passes.”

The cusp provides easy access to the Earth’s boundary with interplanetary space, allowing a unique perspective on how magnetic fields all around Earth interact with those from the Sun. In a process known as magnetic reconnection, the field lines explosively reconfigure, accelerating particles to velocities reaching a significant fraction of the speed of light.

“Over the planned one-year mission, the identical satellites will be outfitted with a combined total of 10 instruments to measure the plasma and fields in over 3,000 cusp crossings,” said SwRI’s Ron Black, the TRACERS mission manager. “This will allow us to determine reconnection variability over a wide range of solar wind conditions.”

TRACERS’ principal investigator is Dr. Craig Kletzing from the University of Iowa in Iowa City.

Defending Against an Electromagnetic Pulse

While the COVID-19 pandemic is disrupting life around the world, for the San Antonio Electromagnetic Defense Initiative Task Force, the pandemic is highlighting vulnerabilities that could be amplified by a different type of disaster. The task force is preparing for the emerging threat of an electromagnetic pulse (EMP), a manmade or natural burst of powerful electromagnetic energy that could cause long-term, widespread power outages. An EMP, in the form of a nuclear blast or solar event, could prove deadly by dismantling critical national infrastructure, including transportation, health care and food and water supplies for weeks or months.

“Take the current COVID-19 crisis as an example. The inconvenience of social distancing and stay-at-home orders have had a devastating impact on the economy and our way of life,” said Jody Little, a manager in SwRI’s Defense and Intelligence Solutions Division, who is providing leadership on two task force steering committees. “Now, take away all power, water, gas, communications and other conveniences. This disastrous scenario could play out during an electromagnetic event if we are not prepared.”

SwRI is a founding member of the San Antonio Electromagnetic Defense Initiative, established by the U.S. Air Force and Joint Base San Antonio (JBSA) in March 2019 in response to federal requirements to coordinate a national resilience against an EMP. The local initiative supports collaboration among the city’s government, military, research, academic, business and utility partners to prepare San Antonio for an electromagnetic event, with a key focus on domestic electromagnetic spectrum operations (DEMSO). DEMSO will establish policies and doctrine to ensure continued commerce, comfort, sustained military operations and a swift recovery after an EMP event. Little is chair of the DEMSO steering committee.

“The purpose of DEMSO is to create electromagnetic defense policies and ensure a well-defined doctrine is inserted into emergency plans,” Little said. “We are also looking beyond our local community and envision being the blueprint for national policy by providing direction, examples and lessons learned.”

In May, the Department of Defense (DOD) designated JBSA and San Antonio as a national pilot program for grid resilience and long-term power outages, the first national test site for electromagnetic defense. In June, the Office of the Undersecretary for Defense for Research and Engineering designated Joint Base San Antonio an official 5G experimentation site for two major DOD program trusts, 5G Core and Security and 5G in Telemedicine. The combination of these two major program thrusts will make JBSA the largest DOD 5G experimentation site in the DOD portfolio.

Supporting Satellite Servicing

Using critical docking avionics provided by SwRI, the first Mission Extension Vehicle (MEV-1) successfully docked with a client satellite on February 25, 2020. SpaceLogistics, a wholly owned subsidiary of Northrop Grumman, selected SwRI’s Rendezvous and Docking Avionics Unit (RDAU) for its MEV-1 docking system.

MEV-1 is the industry’s first satellite life-extension vehicle, designed to dock to geostationary Earth-orbiting satellites nearly depleted of fuel. Once connected to its client satellite, MEV-1 uses its own thrusters and fuel supply to extend the satellite’s lifetime. When a satellite no longer needs service, MEV-1 will undock and move on to the next client satellite needing support.

“Keeping satellites running beyond their typical 15-year design life is an efficiency measure,” said Larry McDaniel, who led the program in SwRI’s Space Science and Engineering Division. “There’s value in keeping satellites running beyond their design life when they are continuing to function well overall but are unable to maintain orbit unassisted.”

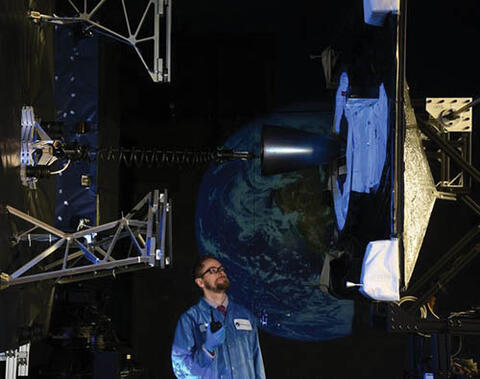

Courtesy of Space Logistics/Northrop Grumman

SwRI developed critical docking system avionics for a satellite life-extension service vehicle, shown here in a laboratory demonstration.

The SwRI-developed RDAU manages critical, real-time information to facilitate MEV-1 satellite docking. The highly configurable, programmable data processing platform provides advanced on-orbit capabilities, including high-speed signal processing. The SwRI RDAU includes vision processing capabilities, supporting multiple camera interfaces. This provides high-performance processing and field-programmable gate array (FPGA) platforms for camera-data routing and image processing.

“We designed the RDAU with an image-processing FPGA that can be programmed in space,” McDaniel said. “Usually you can only program these on the ground, prior to launch. With our system, MEV-1 operators will be able to add new system capabilities by reconfiguring the FPGA on orbit, a first for this particular device.”

The 2,330-kilogram MEV-1 launched last October and has since been using its electric propulsion system to reach geostationary orbit. Now connected to the client satellite in a stacked configuration, the spacecraft will undergo a series of tests and checkouts.

SwRI Supports Medical Manufacturing

SwRI has helped forge the Medical Manufacturing Alliance of South Central Texas. Made up of economic development, manufacturing and research organizations, MMASCT was initially launched to help meet needs for locally manufactured medical supplies in response to the COVID-19 pandemic.

The alliance is an active collaboration between the San Antonio Manufacturers Association (SAMA), Texas Manufacturing Assistance Center (TMAC) South Central Region, SwRI, Fusion Success Group and Bexar County’s Economic and Community Development Department.

Alliance members began sharing resources with local manufacturers in response to social distancing orders and a spike in demand for personal protective equipment (PPE) and essential medical supplies.

“The immediate focus is to help the regional manufacturing sector to identify products and source materials so they can retool plants to meet these needs,” said Bill Rafferty, who leads the TMAC South Central Region office based at SwRI.

The alliance is also helping local manufacturers identify the health and safety standards for face masks and other medical equipment. In cases where items are still useful but not yet approved with official agencies, the alliance is recommending labeling to alert health care professionals and end users.

SwRI supports the alliance by testing equipment, evaluating materials and conducting collaborative research with several local and national universities and research institutions.

“We have already seen a number of innovations through our collaborative research efforts,” said Executive Vice President and COO Walt Downing, P.E. “There is a great deal of ingenuity and capability to meet demand for medical equipment and build in some support for a local supply chain across several manufacturing sectors.”

SAMA is providing a series of webinars and panel discussions to help manufacturers navigate this pandemic.

Accelerating COVID-19 Drug Development

SwRI scientists are using Department of Defense supercomputers to virtually screen millions of drug compounds in pursuit of possible treatment options for the novel coronavirus. The Henry M. Jackson Foundation for the Advancement of Military Medicine awarded SwRI a \$1.9 million, one-year contract to support efforts to develop a COVID-19 therapy.

Working with the DOD High Performance Computing Modernization Program, SwRI is using its Rhodium™ 3D drug development software to screen millions of potential drug compounds. Supercomputers speed up the process, increasing screening capacity from 250,000 compounds a day to more than 40 million compounds in a week.

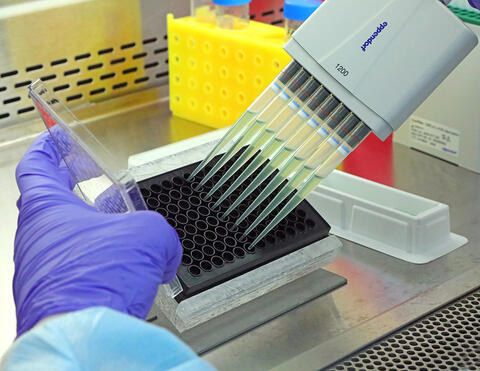

After screening millions of compounds as potential treatments for COVID-19, SwRI conducts cytotoxicity testing on the most promising candidates.

"This grant will enable SwRI to collaborate to develop safe antiviral drug therapy treatment options for COVID in record time,” said Dr. Joe McDonough, director of SwRI’s Pharmaceutical and Bioengineering Department.

As a drug development tool, Rhodium helps scientists predict how protein structures in infectious diseases will bind with drug compounds to find viable candidates to develop into therapies.

“Rhodium is helping us quickly identify highly probable compounds from databases with existing drug candidates to narrow down our focus,” said Dr. Jonathan Bohmann, who is leading the COVID-19 drug screening work. “As we identify potential candidates, we have moved them on to testing.”

SwRI uses laboratory tests to assess the toxicity of compounds to help narrow down potential treatment options. Once compounds are tested and meet the criteria set for safety and efficacy, SwRI will be involved in formulation development and production scale-up for the compounds. The Institute has previously used this process to develop drug treatment therapies for Ebola virus, malaria and other infectious diseases.

“This is definitely a priority project, and we understand the urgency,” said Nadean Gutierrez, who is managing the project. “Once compounds have been identified by Rhodium and then passed toxicity testing, they move to the Texas Biomedical Research Institute for the next steps in testing.”

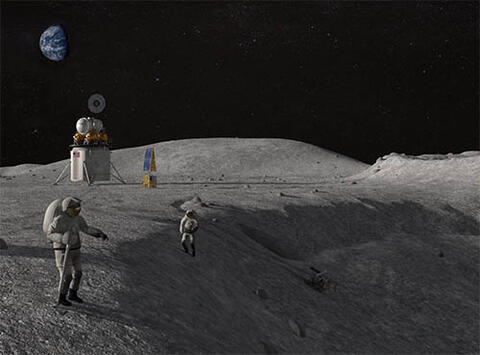

NASA Bets on Lunar LASVEGAS

NASA has awarded SwRI \$3 million to develop a lunar version of its Laser Absorption Spectrometer for Volatiles and Evolved Gas (LASVEGAS) instrument. This spectrometer can precisely measure the volatile compounds present in planetary atmospheres and surfaces — critical information for space science and exploration.

“LASVEGAS is about half the size of a paper towel roll. It’s extremely compact, low mass, low volume and low power — all important characteristics for spaceflight,” said SwRI’s Dr. Scot Rafkin, principal investigator of the instrument. “It can be deployed on the smallest of rovers or landers as well as carried in a single hand by an astronaut sauntering across the lunar surface in search of water ice, methane and other useful resources.”

Courtesy of NASA

The instrument measures gases from planetary atmospheres such as Mars to understand their composition. It can also heat a thimble-sized sample of a planetary surface such as the icy surface of Jupiter’s moon Europa or from lunar soil to determine the composition of released gases.

NASA’s Maturation of Instruments for Solar System Exploration (MatISSE) program provided \$3 million in 2019 to develop the LASVEGAS instrument for application to Europa and similar icy worlds. In 2020, SwRI received an additional \$3 million from the agency’s Development and Advancement of Lunar Instrumentation (DALI) program to adapt the design to operate on the Moon’s surface.

The gas flows into a small, cylindrical chamber where laser light of different wavelengths is bounced back and forth between mirrors on each end. As the light passes repeatedly through the gas in the sample, the different molecular species in the gas absorb the light differently depending on the wavelength. Then the laser light is directed onto a detector that measures its intensity to determine the abundance of the volatile compounds. Each molecular species in the gas has a distinct “fingerprint” of absorption, revealing its overall abundance.

Comparing International Fire Codes

SwRI conducted room burn tests to better understand how country-specific fire codes in the U.S., France and the United Kingdom affect the fire safety of home furnishings and their contributions to flashover. Flashover occurs when temperatures at the ceiling reach 1,000° C and all the combustibles in the room ignite.

Reducing the rate for flashover can save lives, allowing significantly more time for people to escape a fire. The study found the American- and French furnished rooms reached flashover in just five to six minutes, whereas the United Kingdom-furnished room took 22 minutes to reach flashover. Upholstered furniture from the U.K. is treated with the most fire-retardant protection, which also resulted in lower smoke toxicity measurements than the U.S. and French tests.

“Most countries test upholstered furniture for fire performance, however, fire preventative measures and testing standards applied to consumer products vary greatly by country,” said Dr. Matthew Blais, director of SwRI’s Fire Technology Department and lead author of a paper outlining this research published in the journal Fire Technology.

SwRI fire engineers conducted nine room burns to better understand the variances in fire standards from different countries and to study how quickly flashover occurs in a realistic environment. Each of the three identically furnished sets of rooms contained a three-cushion couch, a chair and a flat panel television. SwRI purchased these specific items from each respective country. Each room setup also included an identical coffee table, end table, curtain, bookcase and books, all purchased in the U.S. Because these items are typically not treated with a fire retardant, the fire performance should not vary from country to country. The Institute conducted the room burn tests using the international standard for full-scale room test specifications, ISO 9705.

When the living room furnishings are the first item ignited in a fire, there tends to be a higher incidence of death. SwRI selected three ignition sources of increasing strength, with two representing the passing level for the U.K. standard and one exceeding that requirement to ensure the ability to measure smoke toxicity. For each room configuration, ignition started in the center couch cushion.

The U.S. and France use a smolder-only flammability test standard while the U.K. combines a smolder and open flame ignition test to evaluate the flammability. “In the U.S. and other countries, there is a push to eliminate chemical flame retardants due to an anti-chemical movement,” Blais said. “This study shows the impact of country fire codes only requiring smoldering ignition compared to a country testing with open flame ignition. When an open flame standard is applied to consumer products that have been treated with fire preventative material, the results show the room would reach flashover at a much slower rate, allowing people five to six times more time to escape from a house fire when the first item ignited is a couch.”

Karen Carpenter, assistant director of Fire Technology, and Kyle Fernandez, a fire technology engineer, also collaborated on the study and paper titled “Comparative Room Burn Study of Furnished Rooms from the United Kingdom, France and the United States” (DOI 10.1007/s10694-019-00888-8).

The North American Fire Retardant Alliance and the American Chemistry Council funded the research.

To see a video about this fire study, visit https://youtu.be/wlnAAxOKYLg.

Proposed SwRI/UNH Mission Leaps Forward

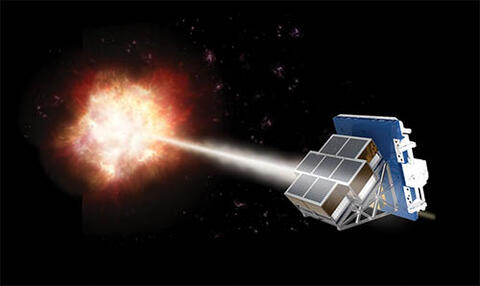

NASA has selected SwRI and the University of New Hampshire to continue developing a mission to look for evidence of distant energetic events, such as the birth of black holes. NASA’s Astrophysics Missions of Opportunity program selected the “LargE Area burst Polarimeter” (LEAP) program for a mission concept study.

Mounted on the outside of the International Space Station, LEAP would study energetic jets such as those erupting from the explosive death of a massive star or the merger of compact objects such as neutron stars. LEAP’s ability to measure the polarization of gamma-ray bursts (GRB) could resolve competing theories about the nature of the jets. LEAP would complement NASA’s Imaging X-ray Polarimetry Explorer (IXPE), scheduled to launch in 2021, which will study lower-energy X-ray phenomena.

Courtesy of SwRI/UNH

“Gamma rays are the smoking gun for some of the most energetic events in the universe,” said Dr. Mark McConnell, director of SwRI’s Earth, Oceans and Space (SwRI-EOS) Department at UNH’s Durham, New Hampshire, campus. “When a very massive star explodes in a supernova and then collapses into a black hole, it ejects jets with energies that can exceed anything observed in the universe since the Big Bang. LEAP will measure the resulting GRB with previously unachievable precision.”

LEAP will improve our understanding of the role that magnetic fields play in these systems, especially with regard to the formation and sustainment of the high-speed jets that are responsible for what we see. It should also reveal how the observed gamma radiation is produced within the jet.

LEAP is a single instrument with nine polarimeter modules based on well-established, flight-proven technologies. It will measure gamma-ray burst polarization while self-sufficiently providing the source localization required to analyze polarization data. These data will allow LEAP to differentiate between classes of GRB models. Detailed time-resolved and/or energy resolved studies will be conducted for the brightest GRBs.

New Emissions Research Facility

SwRI has launched a new automotive emissions aftertreatment catalyst testing facility, expanding the capacity and capabilities of its state-of-the-art Universal Synthetic Gas Reactor (USGR®) technology. These systems simulate real-world exhaust gas conditions to quickly and accurately characterize catalyst performance.

“SwRI’s USGR system allows our clients to quickly determine catalyst performance under a variety of conditions and at a lower cost than with traditional engines or burner systems,” said Dr. Cary Henry, an assistant director in SwRI’s Powertrain Engineering Division. “Accurate control of gas composition and advanced measurement techniques like SPACI-IR (spatially resolved capillary inlet infrared spectroscopy) enable us to develop kinetic models for reactions and understand how aging and chemical contamination affect catalyst materials.”

SwRI uses its novel Universal Synthetic Gas Reactor (USGR®) technology to simulate real-world exhaust gas conditions to quickly and accurately characterize catalyst performance.

Catalytic aftertreatment equipment use a porous ceramic core treated with reactive chemicals that process exhaust and remove potentially harmful gases and particulates to help engines meet increasingly strict emissions regulations. Testing core samples of material used in three-way catalysts, diesel oxidation catalysts, diesel particulate filters, selective catalytic reduction (SCR) compounds and ammonia slip components shows how products perform under different operating conditions. Clients receive the technical information needed to help them develop new catalyst technology and materials.

The Catalyst Technology Center includes two new USGR systems, bringing SwRI’s testing capacity to six systems. The facility allows SwRI engineers to conduct several tests in parallel, improving turnaround time and lowering testing costs.

SwRI’s USGR systems can operate under a wide range of flowrates (7.5 to 65 L/min) and temperatures (100˚ to 1,200˚ C) and are capable of continuous automated testing for up to 60 hours. The system supports as many as 13 metered gases, which can be introduced simultaneously, as well as water or hydrocarbon injection. Testing can be tailored to clients’ needs, but standard tests include reverse and forward light-off tests, four-step protocol for SCR and V-volatility testing approved by the Environmental Protection Agency. The facility also supports thermal and chemical aging experiments.

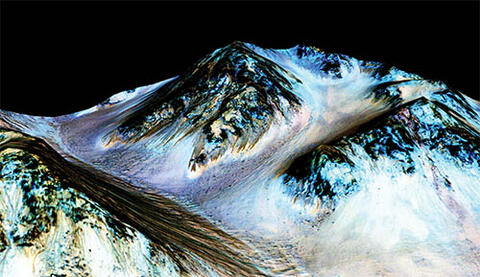

Modeling Mars' Inhospitable Climate

An SwRI scientist modeled the atmosphere of Mars to help determine that salty pockets of water present on the Red Planet are likely not habitable by life as we know it on Earth. A team that also included scientists from Universities Space Research Association (USRA) and the University of Arkansas helped allay planetary protection concerns about contaminating potential Martian ecosystems.

Due to Mars’ low temperatures and extremely dry conditions, a droplet of liquid water on its surface would instantly freeze, boil or evaporate — unless the droplet had dissolved salts in it. This brine would have a lower freezing temperature and would evaporate more slowly than pure liquid water. Salts are found across Mars, so brines could form there.

Courtesy of NASA/JPL-CALTECH/University of Arizona

“Our team looked at specific regions on Mars — areas where liquid water temperature and accessibility limits could possibly allow known terrestrial organisms to replicate — to understand if they could be habitable,” said SwRI’s Dr. Alejandro Soto, a senior research scientist and co-author of a study published in Nature Astronomy. “We used Martian climate information from both atmospheric models and spacecraft measurements. We developed a model to predict where, when and for how long brines are stable on the surface and shallow subsurface of Mars.”

Mars’ hyper-arid conditions require lower temperatures to reach high relative humidities and tolerable water activities, which are measures of how easily the water content may be utilized for hydration. The maximum brine temperature expected is -55° F — at the boundary of the theoretical low temperature limit for life.

“Even extreme life on Earth has its limits, and we found that brine formation from some salts can lead to liquid water over 40% of the Martian surface but only seasonally, during 2% of the Martian year,” Soto continued. “This would preclude life as we know it. These new results reduce some of the risk of exploring the Red Planet while also contributing to future work on the potential for habitable conditions on Mars.”

Fuel Processing Capabilities Expanded

SwRI has expanded its capacity to develop and certify fuels from alternative sources with a new, custom fixed-bed reactor. The SwRI-designed system can be used for refinery processes, such as hydrotreating and hydrocracking, to produce stable fuels ready for vehicle use.

Hydrotreating is an established refinery process for reducing sulfur, nitrogen, oxygen and olefins in fuel and lubricant products. Refineries use hydrocracking to adjust the properties and boiling point ranges of crude oil fractions into products such as gasoline, kerosene, jet fuel and diesel.

“Developing reliable biofuels can help reduce the world’s reliance on fossil fuels,” said Eloy Flores III, assistant director of SwRI’s Chemical Engineering Department. “SwRI is a leader in developing fuels from unconventional sources, producing biofuels that meet Environmental Protection Agency specifications. The Institute also is home to one of the few laboratories in the United States to register alternative fuels for integration into the mainstream vehicle fuel supply.”

Alternative or biofuels are developed by converting raw materials such as corn, algae, plastics, wood or even heavy crude oil into refined fuel. SwRI’s new reactor includes a large reactor bed and two additional smaller units to develop processes to produce fuel samples. The pilot system can process and produce up to two drums of specification fuels per day, operating at up to 3,500 psig and 550° Celsius.

“Combining the large reactor bed with smaller units allows us to handle various feed materials ranging from Fischer-Tropsch waxes to naphtha,” Flores said. “We help our clients take an unconventional feedstock, such as pyrolysis oils, and produce biofuel blends that can be used in cars, buses, trucks and jets. Our goal is to provide more efficient scale-up and proof-of-concept techniques for processing fuels and other chemical products for our clients.”

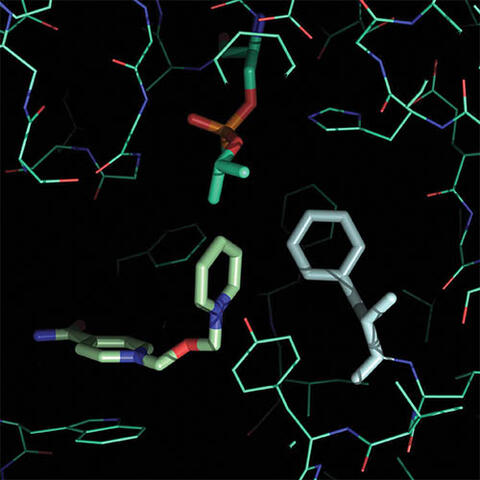

Developing Nerve Agent Antidote

SwRI has received funding from the Medical CBRN Defense Consortium (MCDC) administered by Advanced Technology International to develop a nerve agent antidote for emergency use on the battlefield or to protect public health.

SwRI-developed Rhodium™ software helps scientists discover nerve agent antidotes that penetrate the central nervous system. This 3D display illustrates how a potential antidote interacts with an agent.

The use of nerve agents continues to be a significant threat to both military and civilian populations. This prototype medication could serve as a countermeasure against a nerve agent attack. SwRI will lead the development of the antidote under the \$9.9 million, five-year program. It will collaborate with the University of Pittsburgh on the synthesis and compound design, through the support of the Defense Threat Reduction Agency (DTRA).

“This antidote improves on the current standard of care, importantly, its ability to reverse the effects of the toxin in the central nervous system,” said Dr. Jonathan Bohmann, a principal scientist in SwRI’s Pharmaceutical and Bioengineering Department. “The antidote will eventually be administered through an autoinjector, which allows for rapid and effective treatment in the field. It would work much like an epinephrine auto-injector or EpiPen® administered during a severe allergy attack. The initial goal of the project is to support our warfighters; however, this treatment could also eventually be administered for civilian use.”

SwRI will use a computer-based drug design software platform called Rhodium™ to develop the antidote. SwRI developed Rhodium, a proprietary docking simulation software tool, to enhance drug design and safety while reducing costs and speeding up development time. The Institute offers Rhodium as a service to clients. Rhodium supports drug development and screening for antibiotics as well as preventative treatments such as vaccines. The software also predicts adverse drug reactions and side effects.

See COVID-19 Drug Development for more Rhodium news.