Because compressors are designed for gaseous fluids, the presence of a small amount of liquid can have significant effects on compressor performance. In the oil and gas industry, compression of natural gas containing both gaseous and liquid hydrocarbons during upstream production can require as much as twice the power as gas-only compression. In the power generation industry, wet gas compression, termed fogging overspray, routinely occurs when water is injected into the compressor to improve gas turbine output at reduced cycle efficiency.

Our Compressor and Turbine Performance Lab is leveraging expertise in the areas of fluid dynamics, thermodynamics and rotating machinery to study wet gas compression.

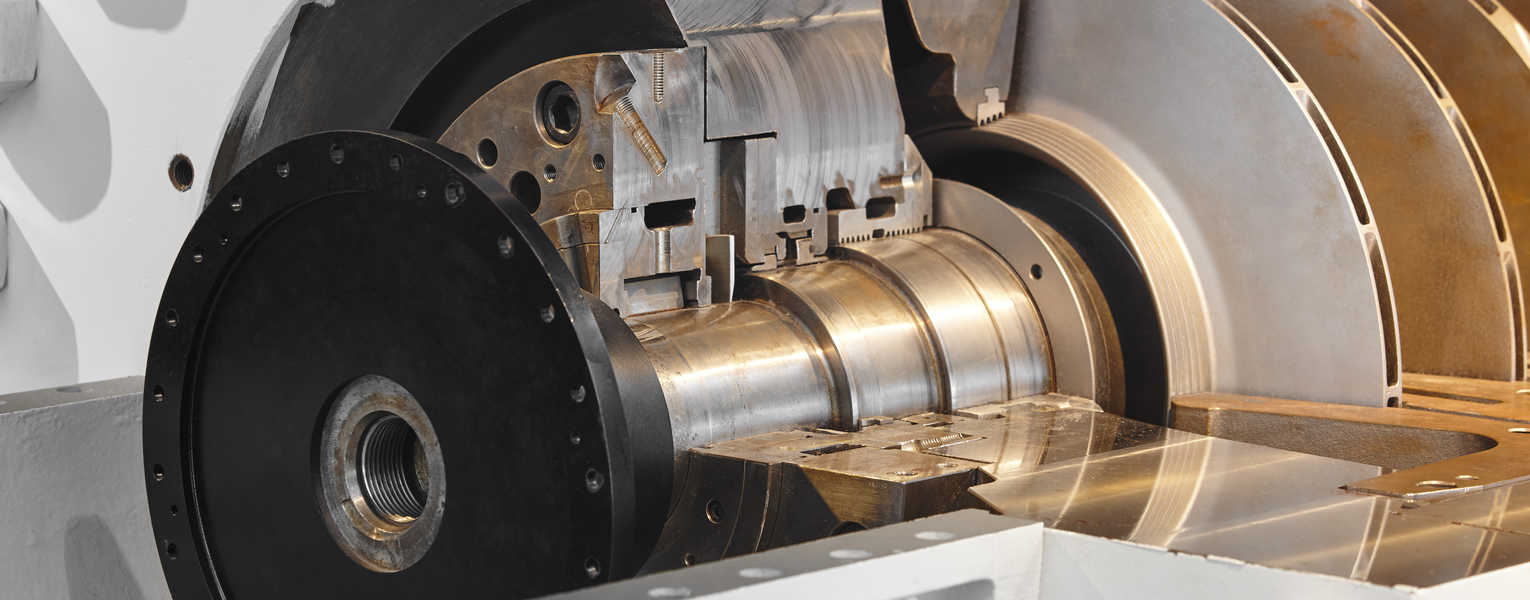

A large-scale wet gas flow loop at SwRI is used to measure compressor and loop operation for wet gas flow.

SwRI is investing in methods beyond conventional computational fluid dynamics (CFD) to improve prediction capability of wet gas compression.

Wet Gas Flow Loop

- High-pressure (300 psia suction), closed-loop test facility

- Interchangeable centrifugal compressor impeller and diaphragms (up to 4 stages)

- Independent control of gas and liquid temperatures

- Gas: air, nitrogen and CO2; Liquid: water

- Liquid injection up to 5% LVF (71% LMF)

Measurement Capabilities

- Instrumentation exceeds ASME PTC10

- Mechanical vibration

- Axial thrust

- Shaft torque

- Static and dynamic measurement systems

- High speed flow visualization

To contract with SwRI, please contact the Machinery Services Hotline at +1 210 522 3000.

For more information, contact Griffin Beck or call +1 210 522 2509.