Background

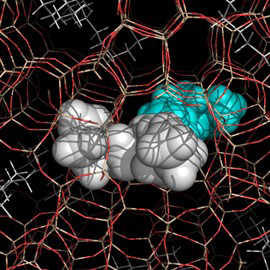

Figure 1: Decane molecule in zeolite cage.

Figure 1: Decane molecule in zeolite cage. The objective of the project was to explore the kinetic modeling capabilities of Rhodium to predict the performance of zeolite catalysts in adsorption and desorption of hydrocarbons. The second part of the project was to washcoat catalyst cores with the best zeolite candidates and conduct hydrocarbon storage testing using SwRI’s Universal Synthetic Gas Reactor (USGR®) system and compare performance results with Rhodium simulations. Zeolites are widely used in NOX-SCR catalysts and as hydrocarbon (HC) traps to meet stringent emission regulations. In diesel cars, zeolite-based HC traps can be used to assist diesel oxidation catalysts (DOCs) during the cold-start period, when the exhaust gas temperatures are below light off temperature of the DOC (200–300° C). Once light off temperature is reached, HCs desorb and are oxidized by the DOC. However, it is very challenging to meet all the requirements simultaneously, due in part to the wide variety of HC mixtures that can be present in exhaust, as well the presence of various inhibitors (such as lube-oil related poisons). These factors can cause changes in diffusive and chemical properties of the zeolite that are not yet well understood. Additionally, the HC trapping process is largely a physical process dictated by a match between the size of the HC molecule and the size of the zeolite pores. However, SwRI has the capability to find solutions to these challenges using the in-house developed simulation software called Rhodium.

Approach

We proposed using the Rhodium tool to screen various zeolites under conditions that will approximate the exhaust gas environment for this application (Figure 1). The most promising candidate zeolites were identified using the Rhodium data, and wash-coated samples of these candidates were prepared for laboratory validation tests. SwRI utilized the USGR system to conduct experiments on the zeolite candidates. Data from these tests were compared to predictions from the Rhodium model to validate accuracy.

Accomplishments

Of the four zeolites selected, ZSM-5 with high silica/alumina ratio showed superior hydrocarbon storage. Rhodium could predict the storage trend for the zeolites. However, there were several discrepancies between the simulations and the test results. The simulations did not account for strong bonds such as H-bonds and covalent bonds. There was no flow direction; therefore, simulations were unable to provide space velocity variations. The structures simulated were idealized structures with 100 percent silica to alumina ratio. Unfortunately, no production zeolites were available with an ideal structure. Therefore, some discrepancies in the results stem from the lack of data for actual zeolite crystal structures.

Rhodium has immense potential to predict hydrocarbon storage in zeolites. However, several improvements will need to be made to the software for quantitative measurements, such as bond energies to predict strong bonds between zeolite and hydrocarbons and the ability to simulate flow direction. It would also be helpful to conduct crystallography on zeolites and use that data for simulations. Overall, the project met its goal of validating the Rhodium software as a useful tool to predict hydrocarbon storage.