Background

The focus of this disruptive internal research project is to evaluate the potential use of non-circular holes for diesel injector nozzles. The first phase of the program was focused on determining if diesel injector nozzles with an advanced design could be produced. In the second phase of the project, experiment of the fabricated nozzles was carried out with a constant-volume combustion chamber (CVCC). Spray patterns of different nozzles were obtained from several optical setups and compared to provide key performance measures, including spray penetration, cone angle, and level of mixing. The completion of the project demonstrates a functional advanced nozzle design that could be applied to a diesel engine and provide a possible strategy to utilize their design for reduction of soot.

Approach

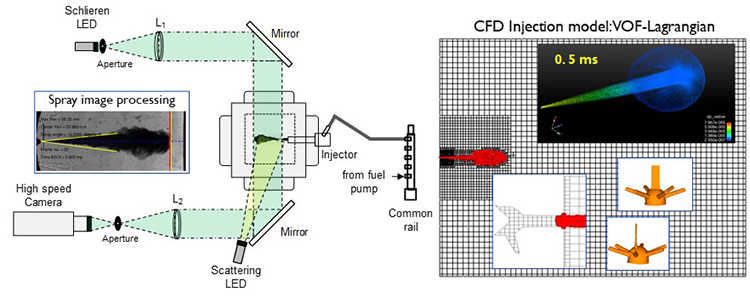

High-speed imaging was used to measure spray penetration under the controlled ambient environment of a spray chamber. Spray profiles were then used as validation for developed models including a computational fluid dynamics (CFD) simulation that used actual nozzle geometry as an input.

Figure 1: Experimental Setup (left); CFD simulation with VOF-spray one-way coupling approach (right)

Accomplishments

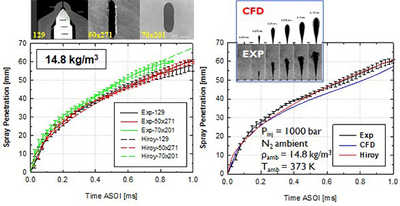

Figure 2: Spray profiles from spray experiment of different nozzle geometries (left); Comparison between experimental and numerical results (right).

Figure 2: Spray profiles from spray experiment of different nozzle geometries (left); Comparison between experimental and numerical results (right). A method to produce non-circular nozzle holes for diesel injectors was demonstrated. The spray penetration was characterized and compared with traditional nozzles with circular holes. A CFD model was developed for the non-circular nozzle and the simulation results had good agreement with experimental measurements. The longest spray penetration was observed for non-circular nozzle with an aspect ratio (minor-to-major axis) of 70:201. A simplified spray model based on Hiroyasu’s work predicted the shortest spray penetration can be achieved with an aspect ratio of 0.65. Further research is under consideration to characterize the combustion performance of the non-circular nozzles compared with traditional nozzles.