Background

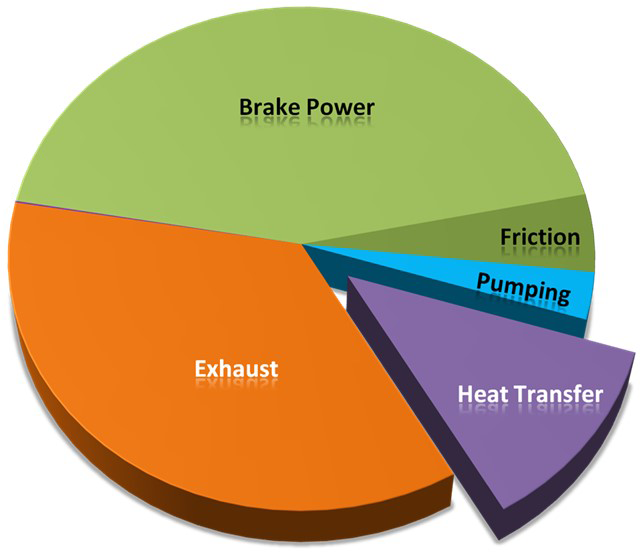

Thermal insulative coatings are an area of high interest in the diesel engine community; these coatings offer the potential to reduce heat losses through the piston to the engine oil and coolant. The energy can then serve to increase the engine power output and to increase exhaust temperatures, which is useful for aftertreatment thermal management and waste heat recovery. However, the design and development of these coatings is experimentally challenging as it is impossible to directly measure temperatures of the piston surface with these coatings.

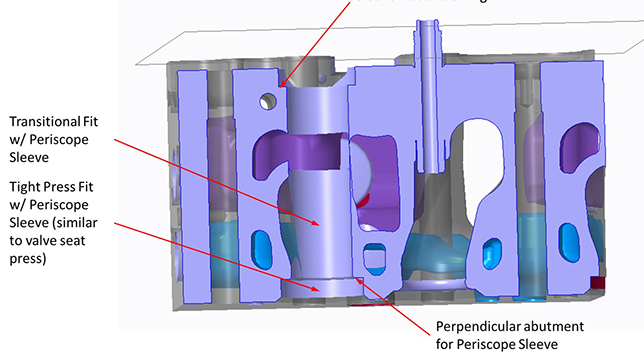

To address this gap, the present project is designing and installing an optical periscope into the cylinder head of a single-cylinder diesel engine and applying a non-contact phosphor thermometry method to directly measure the surface temperature of the piston both with and without the insulative coating. These measurements will serve to validate CFD and FEA models of the coating, and to quantify the performance of the coatings in situ.

Figure 1: Energy Flow Distribution in a diesel engine.

Approach

An optical periscope was built to replace one of the exhaust valves on the engine. A yttrium aluminum garnet phosphor applied to the surface of the piston emits a temperature-dependent spectrum between 450-500 nm when illuminated with a 355 nm laser. Measurement of the spectral features from this phosphorescence allows for a direct measurement of the temperature of the piston surface.

Figure 2: Optical periscope arrangement

Accomplishments

Spectral data have been acquired for a phosphor-coated steel piston. Correlation data to convert the spectral lines into a temperature measurement will be collected to complete the work and validate the experimental method and thermal models of the combustion-piston system.