Background

As the automotive industry moves towards electrification, certain areas of the industry will turn to fuel cell technology. Since fuel cells are much more energy dense than current battery technology, they will be the ideal zero-emissions choice for HD/MD applications. The 2021 Toyota Mirai is a state-of-the-art fuel cell powered vehicle on the market. Benchmarking the 2021 Mirai will provide SwRI with valuable data and experience that will propel SwRI into a player in fuel cell research and development and help pave the path for SwRI to become a supplier of fuel cell testing services. The target of this program is to determine and develop best practices for (a) benchmarking fuel cell vehicles with on-road and chassis dynamometer testing, (b) evaluate the thermal management and fuel balance of plant. This project will help pave the path for SwRI to become a supplier of fuel cell testing services.

Approach

A 2021 Toyota Mirai will be instrumented to measure the power flow of the individual components and systems in the powertrain. On-road tests will be conducted at the SwRI test track to evaluate the fuel cell control strategies at different acceleration rates, cruise speeds and lithium-ion battery SOC levels. Dyno-tests will be conducted in compliance of SAE J2572 to evaluate the fuel economy of the vehicle. Thermal testing will be performed by soaking the vehicle in cold and hot environments. Cold starts and the impact of temperature on the fuel cell’s health will be evaluated.

Accomplishments

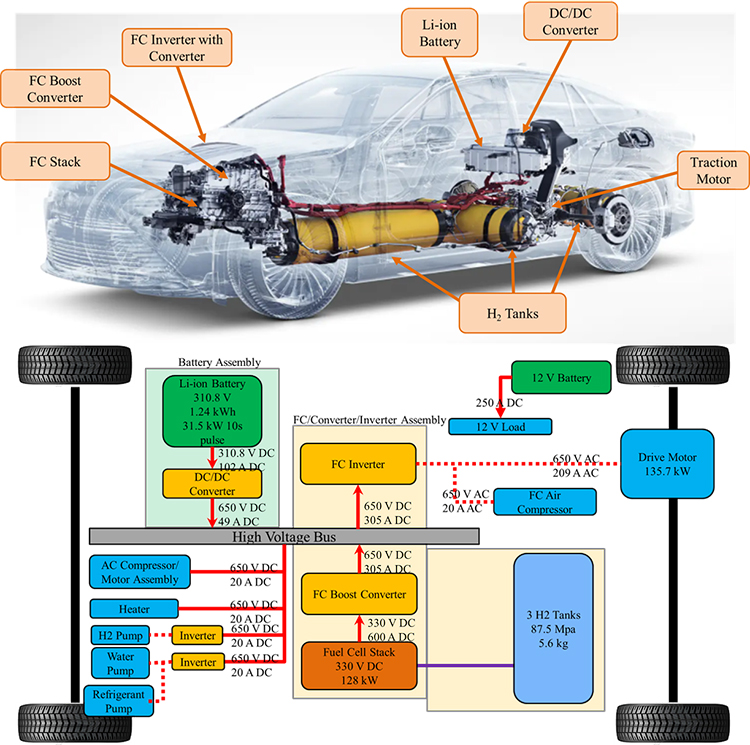

A 2021 Toyota Mirai has been purchased and instrumented. The vehicle is powered by Toyota’s state-of-the-art 128-kW humidifier-less fuel cell system and has three hydrogen tanks (Figure 1 top). The key powertrain components were identified, and the structure of the powertrain is shown in Figure 1 bottom.

Figure 1: (top) 2021 Toyota Mirai key components. (bottom) Power structure.

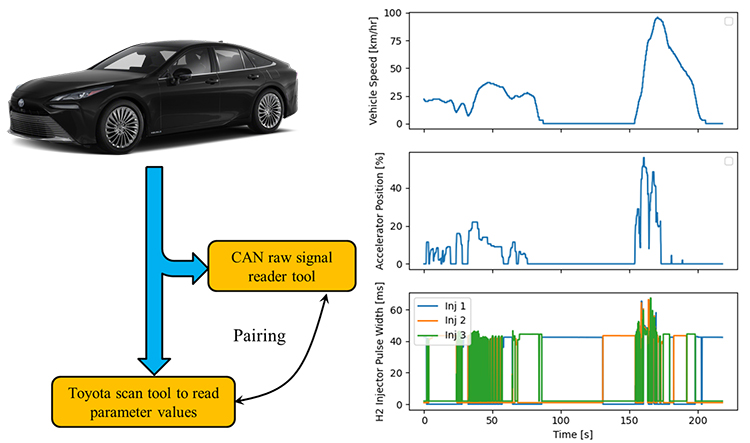

Selected CAN signals were reverse engineered by pairing the CAN parameters from the Toyota scan tool and the CAN raw message reader tool (Figure 2). Having access to CAN signals will significantly alleviate the instrumentation requirements by providing information that is not readily accessible by deploying sensors.

The test program has started.

Figure 2: CAN signal reverse engineering (left), example CAN signals (right).