Background

Composite materials have become a critical component to enable current high-performance aerospace systems. However, fabrication of the composite-based parts in these systems is still a time-consuming and expensive process, with significant manual labor required to lay up sheets. This project involved further development of technologies to autonomously layup composite material plies. The goal of the overall project was to design and construct a robotic workcell with the capabilities needed to perform automated composite layup on a mold. The work was overall in collaboration with Advanced Robotics for Manufacturing Institute (ARM), the University of Southern California (USC), and Lockheed Martin. USC recently led a project, funded by ARM, which demonstrated a complete workcell for autonomously laying up a part with support from SwRI on the system architecture and the operator interaction system. In parallel, SwRI internally developed complementary technology for additional parts and layup methods.

Approach

The approach for this project involved determining algorithms to autonomously define and plan robot motions to handle sheets of woven composite fibers with two robots. One robot was tasked to hold a sheet above the mold and let it hang loosely while the other robot used a tool to press the sheet onto the mold, conforming it to the mold geometry, which is known as draping. Given the mold geometry was known ahead of time, the challenge was to generate a sequence the individual robot motions to achieve a consistent drape over the full surface of the mold. At this stage in the solution development, the approach assumes an expert operator who can input information about which high-level regions of the mold should be draped and in what order. The software can then take over and determine a set of paths for the draping tool to follow over the surface of the mold, using some high-levels parameters controlling the draping behavior. Motion planning software is then used to find robot trajectories that follow the desired paths. In the end, the framework enables the full layup of mold with multiple plies with a consistency comparable to a human operator.

Accomplishments

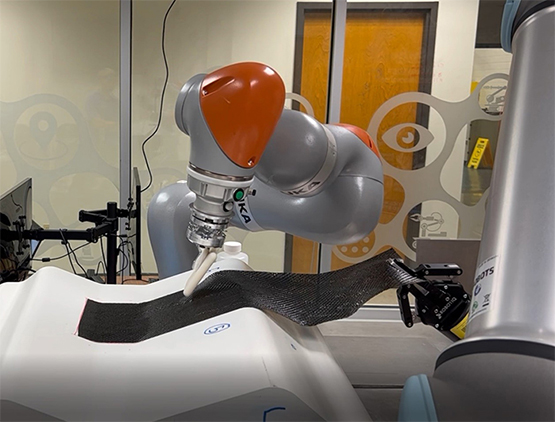

The project successfully demonstrated a functional robot workcell with the capability to layup full parts. The related ARM-funded project concluded successfully, with the robotic system at USC performing a complete layup of a large aerospace part mounted on a rotating mold. This system made use of SwRI's operator interface software for monitoring the layup progress. And at SwRI, a workcell with two collaborative robots is operational and capable of performing layup of two different mold geometries.

Figure 1: Two collaborative robots work to autonomously layup a ply of composite material on a complex mold.