FlawPROTM is a computer program developed and validated by Southwest Research Institute (SwRI) against full-scale pipe test data as part of a Joint Industry Program (JIP) titled Validation of a Methodology for Assessing Defect Tolerance of Welded Reeled Risers and Flowlines that involved major companies in the offshore industry, including oil companies, pipe manufacturers, and pipeline installers. Although designed to perform engineering critical assessment (ECA) for pipes subjected to high strain when installed by the reeling process, FlawPRO can also perform ECA for conventionally installed pipes.

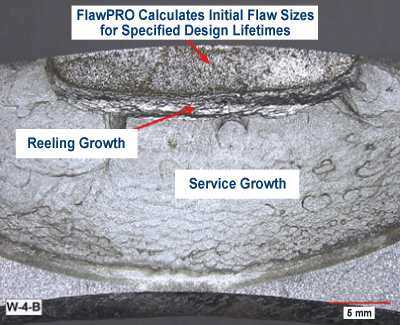

Illustration of failure from reeling and service fatigue during full-scale testing of pipes.

What Makes FlawPRO Different?

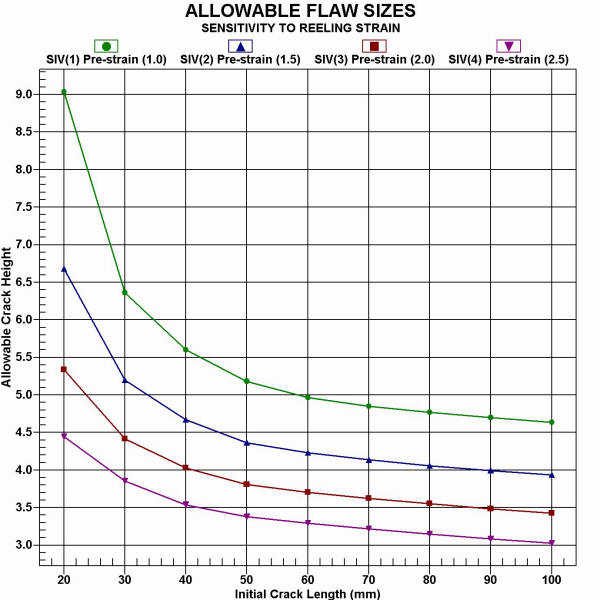

FlawPRO will automatically calculate acceptable flaw sizes that can be used to set inspection limits for welds. The methodology used to determine flaw extension during reeling is based on a validated physical (tear-fatigue) model that incorporates both ductile tearing and low cycle fatigue.

What Are the ECA Calculations Performed by FlawPRO?

- Lifetimes under service, reeling, and service, and reeling conditions

- Flaw extensions under service, reeling, and service, and reeling conditions

- Acceptable flaw sizes for inspection under service, and reeling and service conditions

- Critical flaw sizes

What Technologies Are Employed in FlawPRO?

- J estimation scheme based on finite element analysis database - equivalent to BS 7910 Level 3C (J-based) Failure Assessment Diagram (FAD) approach

- Weight function method for stress intensity factors

- Limit loads derived from finite element analyses

- Validated tearing and low-cycle fatigue flaw extension model for reeling

- BS 7910 based stress analysis for weld geometrical discontinuities and misalignment

Has FlawPRO Been Used on Projects?

Example ECA calculation of acceptable flaw sizes for inspection computed using FlawPRO.

FlawPRO has been used to perform ECA to derive acceptable flaw sizes in support of offshore projects involving pipes installed by the reeling process and using conventional installation methods.

What Validation Is Available for FlawPRO?

Full-scale tests on pipes containing weld flaws subjected to a range of reeling scenarios and simulated high cycle fatigue service loads. Some of the validation results can be seen here.