Earth Day is April 22. This month, we’re learning about an Earth-friendly recycling technique turning piles of plastic into useful chemicals and fuels. Billions of tons of plastic are discarded in landfills. Much of it ends up in oceans in places like the Great Pacific Garbage Patch. Irresponsibly dumped plastics disrupt the environment and harm wildlife. A team at SwRI has a solution. They are fine tuning a process to turn mountains of plastics into an oil, which can then be turned back into plastic, other chemicals or fuels. They are also helping big companies enter a new era in plastics recycling.

Listen now as SwRI Chemical Engineer Eloy Flores discusses pyrolysis for plastics, a new way to recycle and clean up the planet.

Transcript

Below is a transcript of the episode, modified for clarity.

Lisa Peña (LP): Piles of plastic waste often end up buried underground or dumped in oceans, harming wildlife and the environment. With Earth Day approaching, we're discussing a new way to recycle, turning loads of plastics into useful chemicals and fuels. That's next on this episode of Technology Today.

[MUSIC PLAYING]

We live with technology, science, engineering, and the results of innovative research every day. Now let's understand it better. You're listening to the Technology Today podcast presented by Southwest Research Institute.

Hello, and welcome to Technology Today. I'm Lisa Peña. Earth Day is April 22. And this month, we're learning about an SwRI program, aimed at protecting the planet from loads of plastic waste. Some estimates suggest billions of tons of plastic waste are piled up in landfills and oceans.

Our guest today is SwRI chemical engineer Eloy Flores. His team is using a process known as pyrolysis to break down plastic waste and turn it into an oil, recycling it for fuels and other useful chemicals. They're also helping big companies enter a new era in plastics recycling. Thank you for joining us, Eloy.

Image Eloy Flores, director in SwRI’s Chemistry and Chemical Engineering Division, says pyrolysis is a game-changer for plastics recycling because the process can recycle mixed plastics, be quickly commercialized and creates a circular economy, efficiently turning low-value waste plastics into valuable products.

Eloy Flores, director in SwRI’s Chemistry and Chemical Engineering Division, says pyrolysis is a game-changer for plastics recycling because the process can recycle mixed plastics, be quickly commercialized and creates a circular economy, efficiently turning low-value waste plastics into valuable products.

Eloy Flores, director in SwRI’s Chemistry and Chemical Engineering Division, says pyrolysis is a game-changer for plastics recycling because the process can recycle mixed plastics, be quickly commercialized and creates a circular economy, efficiently turning low-value waste plastics into valuable products.

Eloy Flores (EF): Well, thank you, Lisa.

LP: So let's start at the beginning. For years, much of the United States' plastic waste that wasn't sent to a landfill or recycled was actually shipped out of the country. Where did it go? And how was it disposed of?

EF: Well like you said, Lisa, most of the recycled plastics are actually sent overseas and not handled within the United States. And where they're ending up, unfortunately, is in the oceans, due to mismanagement on the end receivers of our recycled plastics. But I guess more importantly, 75% of the US plastics that we put in our recycle bins ends up in landfills. So even if you have a recycle bin at home and you put that on the curb, you can expect most of it will end up in a landfill.

LP: That's disappointing, because we put things out on the curb thinking they're going to be recycled, in the hopes that we're doing something good. But how do they determine which items go into recycling and which end up in the landfill? Or why do some of our recyclables end up in a landfill?

EF: Well, mostly it comes down to economics and the ability to sort the materials to make the recycling process efficient. And because that technology is not really - well, the process of sorting hasn't really gotten to the point where it's very efficient or economical to sort the plastics and recycle them. Most of them do just end up in the landfill.

So until there's more advances in that or technologies that can take mixed plastics, or mixed waste plastics - so you avoid the sorting altogether. You take those mixed plastics and then recycle them. Those type of technologies are what is needed to help us avoid either landfilling or shipping our recycled plastics overseas.

LP: What is a mixed plastic?

EF: So a mixed plastic is just everything you throw into your recycle bin, all of that material. There's different types of plastics. And each type of plastic, like a bottle or a film that's maybe part of a package you use that you heat up in your microwave, all of those things are different types of plastics.

And recycling is very difficult when you have these mixed plastics, because they all have different types of properties. And trying to take those different properties and combine them into something that can be recycled is very difficult. So this is where, again, a technology that can take mixed plastics, this stuff almost straight out of your recycle bin, and converting that back into plastics or chemicals or fuels is what is needed.

LP: OK, so I want to go back to talking about some of our plastics, some of the U.S.'s plastic, being shipped out of the country. In 2018, that changed. So what happened?

Image An SwRI engineer sets up equipment for fluidized bed pyrolysis, a process that heats up and breaks down plastic waste for recycling. The process produces an oil, which can be turned back into plastic, useful chemicals or fuels.

An SwRI engineer sets up equipment for fluidized bed pyrolysis, a process that heats up and breaks down plastic waste for recycling. The process produces an oil, which can be turned back into plastic, useful chemicals or fuels.

An SwRI engineer sets up equipment for fluidized bed pyrolysis, a process that heats up and breaks down plastic waste for recycling. The process produces an oil, which can be turned back into plastic, useful chemicals or fuels.

EF: So in 2018, China passed a new policy known as "National Sword." And this policy imported - banned the imports of most plastics and other recyclable materials. So, now, the US had an abundance of waste plastics that they needed to get rid of. And China was no longer accepting them. So then they started sending them to other countries that could handle it. But then those countries quickly became saturated. And mismanagement of those plastic waste made the plastics end up in the oceans. And to just get an idea or to help you visualize how much of these plastics are in the oceans, there's a area of the ocean, which is called the Great Pacific Garbage Patch. So this is off the coast of California. And this garbage patch is actually the size or twice the size of Texas. So if you can imagine two Texases floating out in the middle of the Pacific Ocean as waste plastics, that's a pretty significant amount.

LP: That's a depressing image. How did the waste end up in the garbage patch?

EF: So, again, it comes down to mismanagement by some of the countries, where we've been shipping these mixed, these waste plastics. They're able to purchase these plastics from the United States at a low cost. And then if they can recycle them, they stand to have to make profit. However, most of these places end up - they're actually third world countries. They have a difficult time even receiving the material, much less sorting it. And so as a result, they have piles and piles of waste plastics that ultimately just end up either being washed in the ocean. Or sometimes, even worse, they'll burn them as a heat source, which actually causes other environmental issues with air pollution.

LP: So they were buying our waste plastic in bulk, hoping to make a profit. And that doesn't always work out. So then they have to they get rid of the plastic piles, any way they can. And a lot of that ends up in our oceans.

So this system obviously is broken. It's not working. In 2018, there was a big change, as you mentioned. These countries were no longer accepting our waste plastic. So at that time, your team had a great solution to handle the overflow of plastic waste. Tell us about what you guys did.

EF: Yeah, so, I mean, we've had a long history of working with our clients, doing pilot plant and process development work and with technologies that are in different areas of pyrolysis. So we've done a lot of pyrolysis on things like heavy oil, coal, all type of biomass. And that - so it was a natural transition for industry and for us to look at what opportunities this pyrolysis process had to convert waste plastics into pyrolysis oils. And these pyrolysis oils-- they can then be used as a feedstock for all kinds of different things to produce chemicals or make fuels directly.

LP: So let's talk about pyrolysis. What is it? How do you describe that process?

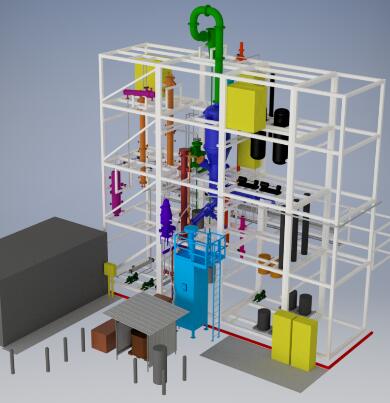

Image SwRI engineers designed this computer model of a plastics recycling pyrolysis unit and then built it for a client. SwRI works with some of the world’s largest chemical companies to help them implement plastics pyrolysis processes.

SwRI engineers designed this computer model of a plastics recycling pyrolysis unit and then built it for a client. SwRI works with some of the world’s largest chemical companies to help them implement plastics pyrolysis processes.

SwRI engineers designed this computer model of a plastics recycling pyrolysis unit and then built it for a client. SwRI works with some of the world’s largest chemical companies to help them implement plastics pyrolysis processes.

EF: So pyrolysis is - it's a very old technology. In fact, some of the ancient Egyptians used to use it to extract methanol from wood for embalming. So it's been around for a very long time. And, basically, it uses high temperature and inert atmospheres. So you don't have air or oxygen around. And when you apply high heat in an inert environment, it allows you to break down the organic material into the more basic molecules. So, more recently, something known as fast pyrolysis has been kind of the go to technology for converting biomass into bio-oils.

And that's the same type of thing that can be used for plastics. And I think one of the keys for pyrolysis and the plastics in this technology, in general, is the ability to handle the mixed plastics, like we talked about, so that you don't have to have a sorting facility. Or you don't have to spend a lot of effort up front sorting the material. And the pyrolysis process is kind of like a garbage can, where it can just take all kinds of different materials and convert them into useful products, in the end.

LP: How does it convert? Because it - is it a burning process?

EF: Yeah, so, again, pyrolysis is traditionally done in an inert environment. So that means there is no air or oxygen around. So we can't - so the air or oxygen is what would cause any type of burning.

So it's a oxygen-free environment. So there's no - so you don't actually burn it. It's just you literally are just heating it to such high temperatures that the molecules are forced to break down into smaller molecules that can be used for other applications.

LP: So as you said, pyrolysis has been used - it's a very old technology. But is the practice of using it for plastics new?

EF: So, yes, I mean, that's the natural shift that we've seen. Many of our clients, who had pyrolysis processes, are now looking at how they can be adapted for plastics. And it makes a lot of sense, I think. It's one of the probably the more robust technologies. There's not a whole lot of commercialized, large-scale, industrial scale pyrolysis processes out there. But that's something, I think, that we're going to see in the near future is a lot more of these pyrolysis plants going online.

LP: OK, so you get a huge pile of plastic. It's mixed plastics. You are able to - are you putting it in a bin or a room? Or where do you put it? Can you walk us through the actual process of starting with a big pile of plastic and then what the end result is, and how you get there?

EF: Sure, so typically the pile of plastics would go through some type of pretreatment process. And in particular, here you - it would probably be shredded so that you have smaller particles of plastics. And then the smaller particles of plastics would then be fed into, what we would call, like a pyrolysis reactor. This is not a trivial thing in itself, because, again, the mixed plastics have many different types of properties, when it comes to things like viscosities and melt points and things like that.

But once you get the plastics fed - once you have the shredded plastics, you put them into some type of feeding device. And then you feed them into this pyrolysis reactor. The pyrolysis reactor is going to be high temperature, anywhere from 500, maybe 700 degrees Celsius. And these plastics will then go into this reactor with a little contact. Typically, we use some kind of heat transfer media. Sand is pretty common.

So these plastics will then contact the surfaces of these hot particles. And that's where the pyrolysis will begin to happen, where the material will initially melt. And then there's such a high heat in there that the chemical bonds will then start breaking between these molecules. And you'll start producing smaller molecules. And then as you produce those molecules, they come out over - out the top of the reactor.

And that can be - those products can be condensed and used for, like we said, fuels or chemicals. There's also another byproduct that typically forms in pyrolysis. And that is the heavier molecules will tend to polymerize or form coke particles, or carbon particles. And what's interesting about pyrolysis and, in particular using circulating fluid as beds in pyrolysis, is that those coke particles can be circulated to a regenerator. And the regenerator will have air.

So the pyrolysis is an inert environment. The regenerator's an air environment. And the air will burn the coke, which then actually adds energy to the process that can be used, again, in the pyrolysis portion. So, in essence, you know, pyrolysis typically has almost its own fuel source. It varies, depending on the type of material you're feeding. So you may have to supplement the regenerator with other fuel. But at least, one of the byproducts of the pyrolysis is something that can be used directly in the process for heat energy.

LP: So the pyrolysis process can kind of, as you said, power itself, which is neat. But the particles that are not used for that are turned into an oil, you've explained to me. Or can you tell us about what are you actually getting out of the process? Like what do you see when it's finished?

EF: Sure, so once the plastics turn into their basic components, those components can serve as a building block for many different types of products. The byproduct, I already mentioned the carbon, but some of the liquid products are what might be called Pygas, or pyrolysis gas. This is very similar to like a gasoline or naphtha type material, at least boiling point range wise. But other than that, the heavier components in these pyrolysis oils, we call pyrolysis oil.

And those can be further fractionated. So you can take pieces of them, depending on what particular components or chemicals you're interested in. In some cases, the pyrolysis oils can be used for something known as naphtha crackers. So a naphtha cracker - there's many of them online in the United States and throughout the world. And they are used to crack these lower boiling point hydrocarbons into ethylene and propylene. And then the ethylene and propylene are your basic building blocks for plastics.

So that's traditionally how plastics are formed. So you could take the plastics and do the pyrolysis process then feed some of those pyrolysis oils into a naphtha cracker, which will then take the plastics you started with and convert them back into the basic building blocks used to make plastics, which make the plastics again. So, in essence, you're chemically recycling the plastics-- well, not in essence. You are chemically recycling the plastics.

And so that kind of makes the whole process cyclic, which is kind of what the world is after right now, or at least industry is kind of looking at - there's a lot of buzzwords around this cyclic plastic processing. And the idea there is you have plastics. You use them. Then you reuse them to make more plastics. So the net result is you don't add any new plastics to the environment.

So the oils, also - there's more you can do with some of the oils. Right now in industry, we're seeing a lot more, what we call, coprocessing, in particular, bio-oils. Some states that have carbon credits, and things like that, they'll use these pyrolysis oils from biomass. And they'll coprocess them. So they'll just mix them with conventional feedstocks to refinery unit operations, things like FCC units. And they'll produce gasoline, diesel, and stuff like that.

So these plastic pyrolysis oils could be used for that, as well. And then there are actually some products of pyrolysis that are very common, things like benzene, toluene, xylene. So some companies are looking at how they can maximize production of those chemicals, which are also used in plastic production but in other industries, as well.

So the pyrolysis oil as a whole has a very large slate of chemicals. And many of our clients are looking at ways of trying to produce specific high-value products.

LP: And you are now helping plastics companies implement this recycling process. So right now, four out of 10 of the largest plastics companies in the world are seeking your input. How are you guiding them?

EF: The goal, I think, for most of our clients is to get to a commercialized process. Most of our clients come to us with a robust, fundamental data that provides the basis for producing larger scale tests. Or they're trying to take basic processing steps that they've done independently and put them all together into a working process. And that's typically what we do. And we call that kind of the pilot scale, which is where we can produce like half a drum to several drums of a product.

So having done a lot of pyrolysis work, you know, we get to use our team's know-how and experience with things like heavy oil residuum and some polymer expertise, as well. And we combine all that to help our clients further advance their technology.

But, as a whole, SwRI has several areas of expertise, from AI and potential plastic sorting technologies to, I mentioned, our polymer chemists helping us find ways to evaluate the feedstock to a pyrolysis unit. Because, as we mentioned, the key here is that we're using mixed plastics. So we're avoiding a lot of the upfront sorting steps.

But what that means is that you also have a feedstock that is potentially changing, as the different variety of plastics are added and taken away. And that can affect your final product. So trying to understand that is another big area for plastics recycling right now.

LP: Can you define feedstock for us? What does that mean?

EF: So, I mean, feedstock for us it means anything that - it's just whatever we're putting into a reactor, I guess, for us. So feedstock could be liquid, could be solid, could be biomass, could be. So in very simple terms, it's just whatever you're feeding into your reactor.

LP: I get it, OK. The goal of this process is obviously to help the environment, to get rid of all this plastic waste, being thrown in oceans, harming wildlife. So how is this technique benefiting the environment, as a whole? What do you see as the big impact here?

EF: So the biggest impact, I think, is to try and remove a lot of these waste plastics from the process of being either landfilled or shipped to other countries. So, again, with pyrolysis being the most amenable to a varying feedstock of mixed plastics, it's probably the most…

We could take most of the surplus, the current surplus of waste plastics, that have either nowhere to go or they're going to end up in landfill and actually turn those back into more plastics or other useful chemicals or fuels. So, in the end, again, it's all about reducing the net outflow of waste plastics. So we can reduce the environmental concerns that the plastics are causing.

LP: So instead of growing landfills long term, do you see more of these plastics recycling - these pyrolysis facilities popping up around the country?

EF: Definitely. I think that we'll definitely see potentially a huge growth in these type of processes, throughout the United States but also in other countries, as well. I know we haven't touched on it, but there's some regulatory things that, in other countries, that are really causing people or industry to make changes to how they process the plastics.

LP: So these pyrolysis facilities themselves do cause some emissions. Is that concerning or harmful?

EF: Right, so the plastic pyrolysis process, it does need to be industrial scale. So that means it's going to require a lot of energy to break down these plastics into their basic chemicals. And because of that, yeah, there's going to be some environmental concerns with emissions and things like that.

But there is a recent report that came out by Good Company that did show that pyrolysis technologies for waste plastics would not produce any kind of environmental issues, with regard to the current regulated emissions, for things that are known as CAP and HAP, which is Criteria Air Pollutants or Hazardous Air Pollutants.

So that is very promising. Because, essentially, if you build more of these pyrolysis plants for plastic recycling, and you put conventional environmental controls on these things, there's really no concerns about regulated emissions.

LP: So the benefits to the environment far outweigh any harm that potential emissions could cause. At this point, the emissions are not a concern.

EF: That's right, I mean, at least based on this first report we've seen from Good Company, but yes.

LP: OK, so I want to go to a question now we did talk about a little bit at the beginning. And as I said, it is disappointing. But many of us already recycle plastics. And we collect them and put them out on the curb. How is your process different? And is it better?

EF: So I guess like we mentioned, a lot of the stuff that goes out in your recycle bin is mechanically recycled. That means, you know, it's gone to some type of sorting facility. They've put all the same types of plastics together. And then they clean them. And then they send those plastics somewhere, where they just get melted and kind of put back into the plastic products.

So this process is better in the sense that it can eliminate the sorting step. There is concern about PVC, or polyvinyl chloride. But that's kind of already sorted out, in most cases. So this process can take the mix plastics, avoid the sorting part. And then not only that, it could be used to make more plastics is one option. But then it could also be used to supplement other markets, depending on the need. So, you know, if fuel prices somehow became higher, then it could be more economical to produce fuels from waste plastics. Or certain chemical markets sometimes become in high demand. Certain chemicals become in high demand, due to production of something.

For example during COVID, we had all these new PPE materials that need to be made. So there was a high demand for certain types of plastics and plastic components or chemicals that are used in plastic components.

So, I guess, that's like we mentioned the huge product slate that's produced from this pyrolysis oils, it gives you the opportunity to apply it to all types of different markets and industries. So, in whole, I think it's a better solution to the conventional mechanical recycling, because it offers so many opportunities in different areas.

LP: Do you eventually see us putting our plastics out on the curbside in our bins on the curb and then going - and those bins going to a pyrolysis facility, at some point?

EF: For sure. I think there's already companies working on that type of thing. And I think we'll definitely see more and more growth of that, especially with the current administration and the way they're funding things for environmental issues. I think, as more and more funding becomes available, then you'll see more municipalities and states and places using pyrolysis, as a way of recycling the plastics.

LP: So you mentioned the garbage patch in the Pacific, which sounds just sad and just awful. So when you see pictures or you hear about these oceans being overrun with plastic waste and knowing you are helping to solve this problem now, how does that feel? That's got to be a good feeling.

EF: Well, I mean, I would say that we tend to focus on the science and engineering part of it all. So actually when I see the oceans with tons of trash and plastic, it kind of makes me feel like we're doing too little too late.

But that's sometimes how we learn and evolve. So I think we at SwRI or I, at least, for sure come in to work every day excited about the opportunities to work on many different things. And I think our passion for what we do here at SwRI really aligns with our clients' objectives and goals. So that really helps us to advance their technologies and not only support their mission but also SwRI's mission in benefiting humanity.

LP: And what have you enjoyed about this work and developing this technique? I imagine that there are many moments where it is fulfilling, even though you see what you're up against, all this plastic waste in the environment. I'm sure there's got to be moments where it just feels good to be helping.

EF: Sure, I mean, yes. I mean, again, we tend to kind of focus on the science and engineering part of it. But, yes, knowing that we have some impact on the environment is important.

Having done pyrolysis type work for about 15 years now, it's - really the enjoyment, I think, for us comes, or at least for me, comes from doing the work, where we're always pushing the envelope on what's already being done. So even though pyrolysis technology has been around for a long time, the work we're doing is not just conventional pyrolysis.

We're looking at better ways and better operating conditions or better techniques to improve the overall process. So we can make it more efficient or make it able to handle the varying feedstocks or produce specific chemicals. So making new discoveries and finding ways to help advance our clients' technology is at least what drives me many of the days to come to work.

LP: What do you consider the most compelling aspect of this technology?

EF: So being able to handle the mixed plastics is very important. I think the sorting step in the current recycling process is what is really slowing things down, with regard to being able to recycle more materials. But, also, and all that ties into the economics of the whole thing. But so being able to process these mixed plastics, I think, is what will be most compelling.

And we've seen examples. And biomass is another good example. Because if you have all this biomass material, then you have it coming from different parts of the country.

And it may be different materials. You may have corn stover. You may have something, switchgrass. And if you combine all these biomasses or even municipal solid waste type materials, the feedstock is so varying that it's really hard to put it into a process and expect to get the same thing out.

And I think that's kind of the challenge right now in pyrolysis is how do you tune these pyrolysis systems so you can get exactly what you want out. And that's kind of the Holy Grail of all this. And that's what we're helping our clients and working on every day so.

LP: So what do you envision for the future of this practice? We've talked about some of the things that could be. But do you see it having a major positive impact on the environment, once all the processes are in place and there are several facilities that are going and accomplishing this?

EF: Yeah, I think, for sure. I think overall the pyrolysis, like I said, will kind of be the go-to process for chemical recycling of plastics. And I think you'll see more and more commercial facilities going online in the future.

And I also mentioned, you know, how biomass and coal - there was a coal to liquids boom for a little while. And these things kind of laid the foundation for what we're doing now, with plastics and pyrolysis. So there's many different so there's lots of opportunity there.

LP: So as Earth Day approaches, many of us are thinking about ways that we can help protect the planet. You know, you don't have to be a scientist or engineer to make a difference. So what is your advice for those of us who just want to make a difference in our day-to-day lives?

EF: Yes, I think whether it's unlikely that your recycle bin that you set out every week will actually be recycled or not, I don't think that matters. I think we should just continue to keep practicing recycling - positive recycling habits. Because the future will likely hold solutions to take advantage of those materials.

I think we're seeing it also, even with the organic waste that we're using. I mean, there's a lot of companies and processes now looking at how to capitalize on those materials.

So don't take for granted, also I think sometimes people take for granted all the plastics that are around them. I think a majority of the items you come in contact with every day have plastics in them. So we're talking about something that's it's a huge part of our everyday life.

And once you understand how much plastics that we use in our everyday life, then I think you can better understand how important it is that we find a way to recycle it or better use it. And, you know, I think it's just, it's like most, this is such a huge problem. But every little bit will help.

So as a consumer, besides the recycling of making sure you do the recycling, if you can afford it, support products that are also made from recycled plastics. I think that'll help drive everything to eliminate this excess and surplus of waste plastics.

LP: For listeners who have heard your approach today and who like what they're hearing, is there a way for us to contribute to this process now? Is there a way for us to give you our plastics to do something which sounds a little bit more environmentally friendly with? Do you accept plastics right now?

EF: [LAUGHS]

LP: Will you take our plastic waste, Eloy?

EF: So we actually have some pilot plants that we've used. And believe it or not, one of our engineers actually collected a bunch of plastic bottles from people. So everyone brought in their plastic bottles. And we worked - the engineer worked to melt them and try to get them into one of these processes. So we have small-scale capabilities right now. So we could probably handle - we couldn't handle everyone's plastics.

But I think in the near future, you'll see you'll definitely see the opportunity, where you can contribute your plastics to something like these waste plastic pyrolysis processes.

LP: That would be great. I think that's something we could all feel good about, contributing to this process. And, yeah, what you guys are doing is just amazing, the eliminating, the sorting process, and really opening this gateway for all plastics to be taken through the pyrolysis process, turned into an oil, and from there becoming useful again.

So much promise there and we look forward to hearing about what comes of all this in the future and just such a great news for the environment. Thank you so much for all you're doing, Eloy, and for taking the time to tell us about it today.

EF: Thank you, Lisa. I appreciate the opportunity.

And that wraps up this episode of Technology Today. You can hear all of our episodes and see photos and complete transcripts at podcast.swri.org. Remember to share our podcast and subscribe on your favorite podcast platform.

Want to see what else we're up to? Connect with Southwest Research Institute on Facebook, Instagram, Twitter, LinkedIn, and YouTube. And now is a great time to become an SwRI problem solver. Visit our career page at swri.jobs.

Ian McKinney and Bryan Ortiz are the podcast audio engineers and editors. I am producer and host, Lisa Peña.

Thanks for listening.

[MUSIC PLAYING]

Using practical and dynamic approaches to advance fuels technology, we work with clients on every step of process development - from lab-scale to commercial design. With diverse backgrounds in biofuels, gas-to-fuels, petroleum processing, and electrochemical processes, our engineers and scientists strive to improve the use of fossil fuels through supporting petroleum and chemical process development for improving costs, efficiency, environmental impacts, and technology advancement.

How to Listen

Listen on Apple Podcasts, or via the SoundCloud media player above.