Rheology is in action all around us, from asphalt that doesn’t melt on a hot day to perfectly melting chocolate. Foods, motor oils, cosmetics and pharmaceuticals depend on rheological data to perform as expected. This field of science examines the behavior of fluids and materials at different pressures and temperatures, specifically measuring how they flow. Rheology makes products we use every day better, easier to use and safer. You can thank rheology for ketchup that’s not runny and lotion that spreads smoothly on your skin.

Listen now as SwRI Sr. Research Engineer Dr. Carlos Sanchez discusses rheology, the “go with the flow” science that’s everywhere.

Transcript

Below is a transcript of the episode, modified for clarity.

Lisa Peña (LP): From motor oil to glue, products we use daily are better because of rheology. Rheology keeps asphalt from melting on a hot day and peanut butter from getting stuck in factory pipes. We're learning about this go-with-the-flow field of science next on this episode of Technology Today.

[MUSIC PLAYING]

We live with technology, science, engineering, and the results of innovative research every day. Now let's understand it better. You're listening to the Technology Today podcast presented by Southwest Research Institute.

Hello, and welcome to Technology Today. I'm Lisa Peña. I recently heard a presentation about rheology by SwRI senior research engineer, Dr. Carlos Sanchez. What struck me is how important rheology testing is to so many industries, yet many of us are not familiar with this field. Simply put, rheology examines the behavior of fluids and materials at different pressures and temperatures. And the findings make products we use every day better, easier to use, and safer. Dr. Sanchez is here to help us understand the role of rheology in our daily lives. Thank you for joining us, Carlos.

Image

Dr. Carlos Sanchez oversees testing in SwRI’s rheology lab. Various industries benefit from obtaining rheological data, including the oil and gas, automotive, food and beverage, cosmetics and pharmaceutical industries.

Carlos Sanchez (CS): Thank you for having me.

LP: So to start, how do you explain rheology? We gave a brief definition there, but what is it?

CS: The definition you gave was great. So, rheology is the study of the flow of matter. So the flow behavior of materials. Everything from water flowing out of a bottle to even plastics that melt and need to flow to form the shapes that they take in the final product. We use it every day where they realize it or not. When we're pouring our coffee in the morning to when we're squeezing a tube of toothpaste to brush our teeth. And it relates to how products look, how they behave. And we're able to analyze and better understand them through rheology testing.

LP: So why do we need rheology? Why is it important to have this type of data available when you're putting out products we use every day?

CS: Rheology basically gives a number or a value that can be used to describe certain phenomena for a particular product. Think of how honey is able to be poured out of a jar or a container, or how something being able to squeeze out of a container, or how motor oil is able to flow through your engine. All those behaviors relate to how it's going to perform in that system or how it's going to look in appearance on a shelf, or on your food, on your plates. Being able to characterize that is very important so that these products behave the way they need to, and they remain consistent from batch to batch, process to process. The appearance and stability of a product that, if it sits on a store shelf, it needs to go from the store to your house and have the same type of consistency. It needs to have a certain shelf life. It needs to last months on end. It's not going to collapse on itself.

Likewise, it needs to perform well in a real system. Say an engine oil running through your engine, it's able to lubricate the parts and flow properly, and likewise, lasts a very long time. You don't want have to change your engine oil every week or so. It needs to last over several thousands of miles. And rheology helps us to better understand those materials, to make sure that they're going to behave that the way they need to at certain temperatures, certain pressures, and certain shear rates, or forces, being acted upon them.

LP: It ensures our condiments aren't clumpy and our motor oil flows smoothly. What other roles does this field play in our day to day lives?

CS: Rheology is used in a lot of industries. It's a very universal science, but it's not very well known. You can see it action through things like confectioneries, like candy. Understanding the flow ability of beverages, like sodas or even just water. The cosmetics industry uses it quite frequently to measure the consistency of makeup, lotions and that sort of thing. But beyond that, being able to understand how fluid is able to be pumped through a factory or how it's applied when you actually get it to your house, whether it's squeezed properly through a bottle or a tube, or even like at the factory, through a nozzle. Those fluids need to maintain a certain appearance, have a certain texture to them for them to actually be used properly. Whether it's a lotion you're rubbing on your skin or if it's peanut butter you're spreading on your toast. All those factors can be better understood through rheology.

LP: So people who rely on rheology testing know all about this field. However, do you find that people in general don't know much about rheology? How do you educate people about this area of science?

CS: That's a good point. Rheology is very universal. Like I said, you see it everywhere. But not many people, unless you actually have done testing before or work in the industry, know what it is. Even some of the clients we work with at SwRI will come to us with a problem that they have. Whether it's the ability of a fluid, they're usually concerned that maybe it's the viscosity. It's too low or it's too high. They're not familiar with what rheology does. With rheology, you can actually look at the internal behavior of a fluid to better understand why it's not flowing properly. Being able to educate people on that, they can better understand how their fluids are behaving. Beyond that just trying to explain with real world examples how rheology can be used in your day-to-day lives in your household, then people can pick up what rheology is.

LP: So one of your star examples of rheology is silly putty. Why is that such a great example of rheology?

CS: Whenever I introduce rheology to people, I always use silly putty because it's such a well-known toy. I'm sure you've play with it at some point or some people have it in their houses now. It has a really fun behavior to it. If you pull it really slowly, it stretches real easily, and you can get it really nice and stringy. If you pull it too quickly, it breaks or it snaps apart. Or you can roll into a ball and actually bounce it around like a rubber ball. That material, or a silly putty, is known as what's called a viscoelastic material. It means that it behaves like a viscous liquid in certain situations or an elastic solid in other situations. But there's a transition point, and that relates to how quickly you're actually deforming the material. If you deform it too quickly, it acts like a rubber, like a solid. If you deform it very slowly, it flows like a liquid. There are a lot of materials that behave like this, just to different degrees not as severe as the silly putty. It really illustrates well how by better understanding rheological behavior, you can see that across many other materials from your day-to-day experiences.

LP: So you mentioned a few of the industries that rely on rheology to make products look good and perform well. Can you just give us a good thorough list of a few of the industries where rheology is front and center?

CS: Sure. Here at SwRI, I'm in the tribology research and evaluation section, and we do a lot of testing in the automotive industry for fuels and lubricants. Being able to understand the rheology of engine oil is very important and also feels like gasoline and diesel fuels. When you're filling up your car with an engine oil, usually it's a certain viscosity grade. It's either a 5W-30, a 5W-20, or so forth. Being able to understand that viscosity and that behavior of that fluid as it's running through your engine is very important in rheology.

Like I mentioned before, you can test fluids at different temperatures. Your engine runs either cold or hot depending on the weather. And also different shear rates if you're running at different speeds in your engine. The fluid need to be able to flow properly, to lubricate all your components, and flush out any debris that's in there. And at the same time, it also needs to have a high lifespan. So you don't want to change your engine oil after a certain number of miles. You want to last a pretty long time. So, automotive uses it pretty heavily.

Another fun one is the confectioneries industry. Candy makers. There's actually some international standards for measuring the rheological behavior of chocolates. You think chocolate, it's a solid at room temperature, but often you have to melt it to get it to flow into different molds to make whatever candy bars that you're making or if you want to drizzle it on some cupcakes or cakes and so forth. That flow behavior needs to be consistent when they're making the chocolate at the factory and also consistent when you take it home and melt it in your kitchen. So having those behaviors consistent throughout is very important.

Another interesting thing about rheology, it also relates to how things taste. There's a relationship you can get based on it's deformation behavior. When you're doing a rheology test, it's going to have what's called a mouthfeel when you're actually eating it. Chocolate is another perfect example of that. It has to have a certain slickness, or certain viscosity, and that relates how well it's going to melt in your mouth and how it's going to distribute along across your tongue and how it's actually going to taste. There's relationships you can establish through that. Same thing with beverages, the way soda's going to taste or the way coffee tastes. There's a whole industry dedicated to coffee rheology and how you can brew coffee at certain concentrations and how it's going to taste, how it's going to feel.

The cosmetics industry is another prime example. So the way lotions or makeup go and spread across your face. Obviously, a makeup needs to maintain its consistency in its container because you don't want to throw it into your bag and have it spill all over the place. It needs to maintain its shape. But at the same time, when you scoop it out with a brush or with your fingers, it needs to shear readily and be able to spread easily on your skin. So all those are rheological behaviors that can be better understood through certain types of tests that we can perform.

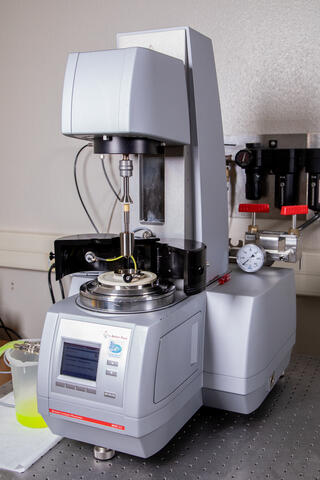

Image

SwRI’s Anton Paar MCR 502 rheometer investigates the flow behavior of various materials such as lubricants, fuels, soft solids, and melts. This highly specialized instrument has a wide range of capabilities, including electrorheology, magnetorheology, pressurized rheology, and dynamic thermal analysis for lubricants.

LP: You had me at chocolate.

CS: OK.

LP: So, yeah. I mean just the wide range of uses is phenomenal. Just pretty much everything relies on rheology And I'm learning new terminology here also. The rheological behavior is a big deal for all of these products. What is rheology testing? It sounds like you're dealing with a lot of different temperatures. And I know we discussed different pressures. Can you break down the testing process for us?

CS: Sure. Rheology, like I said, it's understanding the flow behavior of materials. So you can have different types of systems that can do that. Everything from just simply pouring a material across a slope and just seeing how long it takes to go down that slope. It's a very qualitative way of doing something, but you can use that as sort of a general way of measuring the viscosity of a fluid.

The instrument we use is what's called a rheometer. So rheology and rheometer. That system consists of different tests geometries. So you can, depending on the shape of your material or how thin or thick that material is, you would need to change the container that you use to test it in. If you have like a really flowy type material, like a water, like a really thin material, you would use - you basically place it inside of a cup. And you would have a spindle that drops inside the cup. That spindle will spin at a certain rate, under a certain temperature and pressure, and you can measure its flow behavior that way. If you have something really thick, then you need to basically put it in between two plates, where the bottom plate a stationary and the top plate oscillates, or rotates, with the material in between it. And you can control the manner in which it's deformed.

And we have all kinds of attachments for the rheometer. We can pressurize materials up to 6,000 PSI. We can heat them up to 450 degrees Celsius. We can even cool them down to -40 degrees C using liquid nitrogen. It all depends on what the material requires and it's everyday use. We try to best replicate what it's actually going to be used for. Whether it's in a factory or it's for home use or it's an engine. Whatever that happens to be. The instruments we use are highly adaptable and they just need to know how to implement them to get the numbers that you're looking for.

LP: So ultimately, when you're dealing with a product, let's say peanut butter, and the issue is it's getting stuck in the pipes or something similar to that. So are you trying to decide in this part of the process, it should be at this temperature. But if you move down the chain, this temperature is more ideal. Or as it turns and as you add this ingredient, this temperature works better. Is that sort of like when it comes to production and manufacturing, are you trying to help them solve those kinds of issues?

CS: Yeah. I'm working on a couple of those right now. So the peanut butter one, they're having issues with it pumping through their factory. So imagine it's a pump and it's going through tubes and it's going from one side of the factory to the other. Well the pump needs to go at a certain speed or a certain rate. That rate that it's pumping at, you can relate it to how it's shearing or how it's deforming the fluid, the peanut butter. The other thing too, in most cases, fluids when they're heated to a certain temperature, they get thinner. Their viscosity gets decreased. If it's something that's a lower viscosity, generally you can pump it easier through a tube versus if it's at a colder temperature, it's going to be thicker. It'll tend to solidify a little bit more.

It all depends on what they're able to change at their factory. If you have a large factory with a certain pump that you can't really change the rate of, you don't want to change your pump. But, if you can add a heater on one end of the factory to reduce its viscosity, you can actually pump it easier through that one section without having to change much in your total process. Another thing is the nozzle that it goes through. If you increase or decrease the diameter of the nozzle, it can actually allow it to pump easier at the endpoint when it gets to its final destination, which for peanut butter, it pumps through the jar real easily.

LP: OK. So you're helping them pinpoint these issues along the production route and thinking of ways to make it better.

CS: Correct. So getting back to the actual testing, what I would do in my - on the rheometer would be putting the peanut butter into it and rotating it at a rate that's similar to what the pump would be doing. And then just ramping up the temperature to see what the optimal flow behavior would be achieved at a certain temperature. So they can fine tune their settings at the factory.

LP: So we offer a range of rheological services at SwRI. Can you walk us through those?

CS: Yes. We're the only rheology lab at SwRI and as such, we service a lot of industries. Rheology has applications in many industries like I've mentioned before. We do testing across oil and gas, automotive, we do greases, we do food and beverage, cosmetics, pharmaceuticals. We study paints, adhesives, peanut butter, confections, like I mentioned before.

And we offer many tests for measuring just something as simple as viscosity all the way to the elastic behavior material, or its flow ability, its melting behavior. Even its surface tension or its interfacial relationships to interacting with different materials. There's a wide range of testing services that we can offer and like I said, different temperature ranges, pressure ranges. Even the electrorheology, that's a pretty fun field that we're getting in right now, or how a fluid behaves under electric or magnetic fields. That's becoming of greater interest lately. And just being able understand how fluids just behave in general.

We have clients that want to understand how sticky their material is, if it's a grease. How well it's going to stick to whatever it is they apply it. You can measure that stickiness, or the tackiness, of material. Or creep tests, how well it's going to withstand certain temperatures over a long period of time. We mentioned asphalts before, so there's a whole area related just to asphalts and how they're going to perform well in extreme temperatures. Think of really cold temperatures versus really hot summers here in Texas. Those asphalts need to maintain their shape. You don't want to have a bunch of potholes in your road, so they need to be tested in a certain way and maintain certain behaviors. And we can do that here at SwRI.

LP: What would you say is the most intriguing part of this area of study?

CS: The most intriguing parts - the ones I find to be most fun are when you're doing long time studies on materials. Like I mentioned before, the shelf life of material - it's like a jar of peanut butter at the store. It needs to maintain its consistency over a long period of time. Or an asphalt on the road, it needs to maintain that consistency over a long period of time. You don't want to have to repave your roads every couple of years.

In rheology you can - what I find is really fun is you can take advantage of materials time and temperature dependence. Instead of running a really long test, obviously, you don't want to run a test that's going to take several years testing an asphalt. That's just not feasible. But you can take advantage of its temperature relationship and see how it's going to behave under short time frames and expand on that and create what's called a master flow curve. Those are always really fun to do because you learn about a material's behavior over a wide range of temperatures and time constants, or time frames.

Think of something like a glue. If you've ever glued something before, it's like a white school glue, and you apply it to a piece of paper and you let it sit there overnight to cure, to dry. If you want to have it to dry sooner, you could heat it up. You can put under a hot lamp or you can put a fan on it and accelerate its curing behavior.

We do the same thing in rheology. We can put that material in our rheometer and instead of waiting a long time for it to cure, we can heat it up and reduce the time it takes to cure. And we do that at different temperatures and at different rates. You can basically stitch those behaviors together to understand how the material is going to actually last over a longer period of time. To me, that's always really fun to do and I've done a lot of those lately.

I had one client in particular that had an adhesive. It was a hot metal that adhesive, something like a hot glue. But, they needed to actually have it last a very long time because it's in a certain environment where it's under a lot of stress and various temperatures and so forth. Creating one of those curves really helped them to understand how it's going to behave over those certain time frames without having to test it at those time frames. I always find those to be really fun and interesting.

LP: I definitely wanted to include a discussion about tribology because rheology is under the tribology umbrella. And tribology is something we also do at SwRI. Can you explain that to us a little bit?

CS: Yes. I am in a very unique position in that both of the things I work on most people don't know what they are. Tribology. Give you a quick rundown of tribology. Tribology is the study of friction, lubrication, and wear. Basically how materials interact with each other. Any material that rubs against itself or rotates against another material that's where you can use tribology. And you use it every day from walking down the streets, the way your shoes interact with the road or the hallway, to just anything friction wise. You can use tribology to better understand it.

We do a lot of tests to understand it's friction behavior, how well a component wears, or how well it shouldn't wear with different coatings, different lubricants, and how well it lubricates a system. The way rheology comes into play with tribology is that lubrication aspect for the most part. If you're using a lubricant, like an engine oil or a grease, you can test the friction behavior and the wear behavior of it, but you also understand the flow behavior.

Greases, in particular, are pretty interesting because they have a pretty thick consistency to them. But mainly that thickness and the consistency is mainly meant to contain that oil that's inside that actually lubricates the parts. That thickness to it is just meant to keep it in its location. If you apply a grease instead of a bearing or inside of a gear set, you want that grease to stay there. You don't want it to flow out. Being able to understand its behavior through rheology is very beneficial.

That's basically how I came into studying rheology is through tribology. I got into tribology first and rheology was just supplemental to a lot of the work that I was doing before. And here in the tribology lab, we use rheology to supplement some of our tribology work, but now it's become its own thing where you can just study fluids independently to better understand their behavior. And if needed, we can actually do some tribology test to supplement that.

An example would be - we did a project on bug sprays, which is pretty fun. Think of a bug spray, especially now with all the mosquitoes out in the summer. You spray it on your skin, but you don't want it to be very greasy or very oily. At the same time, it needs to stay on your skin. Understanding that flow behavior of it spraying out of the container and also sticking to your skin and in the tribology aspect of it being not very greasy when you rub your hands across it. Combining those two is something we can look at in tribology and rheology in our lab.

LP: So we've talked about how rheology just does not get a lot of attention but how important it is. Are there any famous rheologists? Or who are your rheology heroes?

CS: In learning rheology, I've read a lot of papers from different authors and different books to learn the subject matter a little bit better. I guess the most famous rheologist is Eugene Bingham. He actually coined the phrase rheology back in the 1920s. So about 100 years ago. Relatively speaking, it's a fairly new science even though it's fairly universal. People have been looking at the viscosity of fluids you know since I guess the dawn of existence. You can always just look at how things flow. Same thing with tribology.

He coined the phrase, and he developed a lot of the theories and practices that we currently use today. I guess most famously, if you've heard the name Bingham before, it's because there's a type of fluid that's named after him, Bingham plastic fluid. These are fluids that behave like a plastic, or an elastic, at steady state or just sitting on a counter or at rest and then start to flow when you apply a stress to them. An example of that is peanut butter or a mayonnaise. Think of peanut butter when you scoop it out with a knife or a butter knife, it leaves a lot of ridges inside the peanut butter. Then you close up the jar and then you get come back to it the next day or a few days later, you can still see those ridges there from the knife from last time you used it. That's like a plastic behavior where it's more of a solid material. It maintains its shape over a long period of time. Of course, when you apply a stress to it, it's able to shear. Bingham was the one that discovered those materials and they were named after him for that reason.

Beyond that, it's hard to name certain people. I mean there are certain authors I usually come across pretty frequently, and I hope to be in that conversation eventually with that the research that I continue doing here at SwRI.

LP: There will be Bingham. 100 years later, Dr. Sanchez. I'm sure of it.

CS: Yeah. Hopefully, we'll see.

LP: Yeah. Any fun facts that you would like to share about your field? You've given us a lot of fun information today.

CS: Fun facts. I'm mainly just giving people examples just so they can better understand where it is. Since I've been doing rheology a lot lately, I always see it in my every day things that I do. One of the things I do as a hobby is woodworking, and I like to put different finishes on my furniture or whatever it is I'm making. If you've ever done woodworking or you paint something, you know there's different types of paints that you can buy at the store. There's different qualities. Some cost more. Some cost less. I've used every range that. I've gone cheaply and bought the cheap stuff from the supermarket kind of place or I've gone higher end. You can definitely tell the difference. In doing rheology testing, I can understand why they cost so much because there's a lot of research that goes into their certain behaviors.

If you're painting something, for example, it needs to have a behavior that's called thixotropy. It's a big word, but basically what that means it has a time dependent flow behavior. Meaning when you take it out of the paint can with your brush and you brush it on to your piece of wood, you'll see the brush strokes there at first. After awhile, the paint will settle, and it reduces viscosity, and it'll give you a nice clean finish. For, cheaper paints you typically don't see that. You'll see all these brush strokes all over the place, and it doesn't really look great. We want to spend a little bit more when you buy higher end house paint or whatever is just you're painting.

Same thing with a wood finish. If you're doing like a clear lacquer finish, if you're playing with a brush, you want those brush strokes to dissipate. You don't want them to be all messy on your nice clean table that you're making. Just coming - being able to understand rheology and you see those things in action every day.

LP: Thixotropy. Is that how you say it?

CS: Yeah. Thixotropy. It's a fun word to say.

LP: Have you become like the rheology guy for your family? Like you're just walking around doing day-to-day stuff and you're like, that's rheology. This is rheology.

CS: Yeah I guess it could be kind of annoying. I mean because I point it out now.

LP: Yeah. I mean I would too.

CS: It's a little more obvious. Thixotropy too. Another example is ketchup. So ketchup - if you ever use the ketchup in a glass jar. I know they don't come in glass jar or bottles anymore. They're usually in squeeze bottles. But if you ever had it in a glass bottle, usually you need to shake the ketchup first to get it to flow out of that glass bottle. That's thixotropy. At rest, the ketchup is really thick, but when you start to shake it, you're agitating it, and you're causing it to flow easier. It starts to flow out of the bottle but then, of course, after awhile, it'll settle again, and it'll recede back into the bottle but you need to shake it. More importantly when you're actually--

LP: That's a great example.

CS: Yeah. And another thing. Well they're squeeze bottles now for the most part.

LP: We've all been there where we understand the ketchup getting stuck in the bottle.

CS: Aside from that when you're squeezing it from like a bottle squeeze bottle onto your french fries, the way that it sits on your french fries is also really important. The appearance. If it's a really runny type of ketchup, it's just going to spread all over your fries and be really messy. But it needs to have a certain thickness, a certain viscosity, to stay and look nice and presentable. There's a lot of research and there's a lot of time to those companies put into that rheology testing to make sure their ketchup goes from the factory, mixing properly in the factory, going into the bottle, and squeezing properly out of the bottle to look nice and presentable on your french fries or your hamburger. And at the same time, of course, tasting really good.

LP: Yeah.

CS: Yeah. Once you learn rheology is, you see it everywhere.

LP: It's everywhere. I have a feeling I'm going to be I'm going to join the rheology club and try to point it out in my day to day life. I mean there's so many examples, it's just overwhelming how much it's used. You think there'd be more talk about this area of science. Good to be learning about it today. We've talked a lot about products looking better and being easier to use, but there is a safety aspect to rheology as well. I imagine, you are making products safer. When the road's not melting while we're driving on it. That type of thing. We're not slipping everywhere.

CS: Yeah.

LP: What is the safety aspect of your work?

CS: There's a lot that goes into it. Like you said, you don't want the products to fail in their intended use. You don't want your engine oil to destroy your engine and have your car break down in the middle of the road. Or you don't want your roads to fall apart. I've done rheology looking at concrete before and how concrete settles. Our clients use their products for a certain application, and they don't want them to fail. Whether it's being used in an automobile or a spacecraft or whatever it happens to be, you don't want those products to fail. Our testing is pretty critical to make sure that we're evaluating properly and giving them the right numbers that they need.

Another aspect related to what's going on now is actually medicines. Injections. You think about a vaccine that's in a syringe and how it squeezes out of that syringe and actually goes into your body. So the flow ability of that medicine inside the syringe. It needs to go out nice and cleanly. You don't want to come out very abruptly or like sporadically. It need to go nice and cleanly. And likewise, the way that medicine is actually dispersed inside your body. It's like a time release thing. So that's all rheology as well. In fact, we do a lot of work also with the pharmaceuticals group at has SwRI looking at microencapsulation of different medicines. Think of pills and how the medicines are how is inside the pills. It's usually like a polymer or a melt, maybe like a wax type material. You can actually see how those materials melts on the rheometer. It's like a body temperature. And how well they're going to disperse throughout over time.

LP: Long term, what impact would you like to leave on the field?

CS: Like tribology, rheology is a very universal subject, but not many people know about it or are aware of it or what it can do for them. Versus a more well-known science like an archaeologist. People know what an archaeologist is and what they do. People know what a chemist does and so forth. But nobody knows what a rheologist is or what a tribologist is. Often, people ask me what I do. I always have to explain exactly what that is. But once they explain it, they understand it because they use it every day. Like, oh you study friction. You study wear. You study how things flow. That makes sense.

One of the impacts I'd like to leave is mainly just educating people on it, and create more awareness of rheology and tribology at the same time. I do a lot of... As often as I can, try to give presentations or give some courses and try to teach people exactly what it is. I also enjoy educating my clients, especially ones that come to us saying, oh I heard what rheology is, but I don't know exactly what we can do. But I know it can be used to help our product. Well, I'd like to educate them on what exactly that is and what it can do for them. Create test profiles that they can use and also explain what the data means, how to interpret it, so that they can then go back and educate their coworkers on what it is and spread the word around.

Beyond that, a lot of the testing we do is used to supplement tribology, in some way. Or it's used to put numbers to certain characteristics that we normally see, like stickiness or tackiness or melting behavior of a material. Eventually I'd like to be able to create industry standards for certain materials because I find there's a lot of industries that use in-house methods of testing their fluids. You may have seen, I've seen TV shows or behind-the-scenes shows where they show how things are made. They'll show a factory that says, oh we've made this product for years, and it's a food product, and the way we test it is we drip it off of some shelf or something or will mix it a certain way and pick it up with a spoon. If it has a certain texture to it, then we know it's good. Well that's really just qualitative. It's just looking at it visually or it takes a lot of experience. That same person has been testing this thing for years. If they taste it, they know it's really good.

If we create a rheological test for that and put a number behind it, we can test it more objectively and put, and more consistently, so that way we can get better performance, better behavior, and more consistent products in the end point. That's what I'm working towards. And I have our own sort of in-house standards for testing certain materials that clients come back to us for. Whether it's a certain temperature sweep that we run or a certain shear sweep or a certain material type. They'll come back to us to the same tests and they'll eventually start building up their catalog of materials using that same test method and replacing those old methods, in-house methods that they have, with these actual numbers and charts that we present to them. I want to keep going with that. Educating people and building up different test methodologies and hopefully come up with different standards that people can use and benefit from.

LP: Well, great mission you have to make rheology more mainstream. You gave us some great examples today to really understand what you do. And it's been wonderful to shine a light on rheology and the type of testing we do it SwRI. Your work is definitely improving our lives, giving us better products, and putting safer options out into the world. Thank you for teaching us about rheology today and thanks for being here, Carlos.

CS: Thank you guys for having me.

And that wraps up this episode of Technology Today. You can hear all of our episodes and see photos and complete transcripts at podcast.SwRI.org. Remember to share our podcast and subscribe on your favorite podcast platform.

Want to see what else we're up to? Connect with Southwest Research Institute on Facebook, Instagram, Twitter, LinkedIn, and YouTube. Check out the Technology Today Magazine at technologytoday.swri.org. And now is a great time to become an SwRI problem solver. Visit our career page at SwRI.jobs.

Ian McKinney and Bryan Ortiz are the podcast audio engineers and editors. I am producer and host, Lisa Peña.

Thanks for listening.

[MUSIC PLAYING]

Rheology testing can provide greater insight into a fluid’s behavior beyond traditional viscosity testing. Southwest Research Institute offers a wide variety of rheological test methods for characterizing fluid behavior.

How to Listen

Listen on Apple Podcasts, or via the SoundCloud media player above.