Automotive coolant, or antifreeze, fulfills the vital role of carrying heat away from internal combustion engines so they can operate efficiently. Coolants are typically ethylene glycol-based concentrates diluted with water, providing boiling and freeze protection for the engine and cooling system. In a circulating cooling system, the flow pathways, radiator and pump are comprised of a variety of metals susceptible to corrosion, wear, cavitation and fouling or plugging from deposits or precipitates caused by incompatible chemistries. The coolant testing laboratory at Southwest Research Institute evaluates coolant formulas to ensure they resist harmful impacts without compromising heat transfer function.

Engine Coolant Testing Services

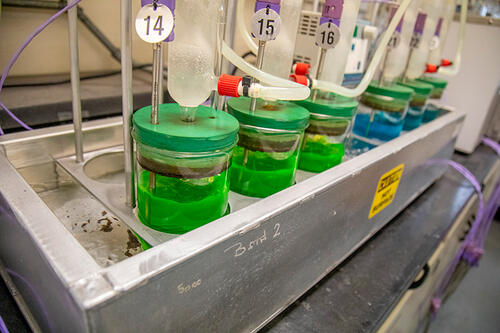

SwRI has the capability to perform ASTM D1384 and to test up to 12 coolant samples in triplicate simultaneously.

Physical and chemical property requirements along with performance criteria for concentrate and predilute coolants are described in ASTM D3306, the standard specification for glycol base engine coolant for automobile and light-duty service. Coolants used in heavy-duty service are tested under ASTM D6210. SwRI’s coolant testing lab routinely runs 14 benchtop and rig tests comprising ASTM D3306 and related D6210 tests.

ASTM D3306 Coolant Testing

SwRI performs the following ASTM D3306 light-duty coolant specification tests.

| D5931 – Relative Density | D1121 – Reserve Alkalinity |

| D1177 – Freezing Point | D1882 – Effect on Automotive Finish |

| D1120 – Boiling Point | D1384 – Corrosion in Glassware |

| D1119 – Ash Content | D2570 – Simulated Service |

| D1287 – pH | D4340 – Corrosion of Cast Aluminum Alloys |

| D5827 – Chloride by Ion Chromatography | D1881 – Foaming |

| D1123 – Water Content | D2809 – Cavitation-Erosion |

ASTM D6210 Coolant Testing

SwRI is home to five ASTM D2570 Simulated Service rigs to ensure testing availability for our clients.

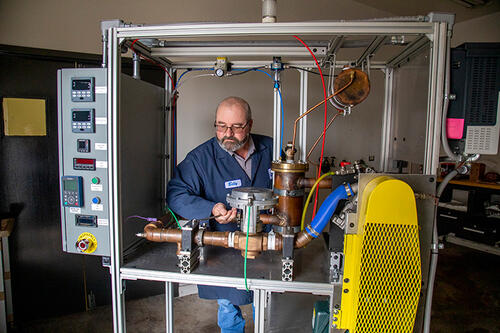

This fully automated and process-controlled ASTM D2809 Cavitation Rig was built and designed by SwRI to evaluate coolant compatibility with aluminum automotive water pumps.

SwRI offers heavy-duty ASTM 6210 coolant testing, which includes the 14 tests under ASTM D3306 in addition to procedures related to concentrations of nitrite and molybdate.

Related Coolant Testing Services

SwRI offers other analytical solutions and services related to coolants and heat transfer fluids, such as thermal conductivity (ASTM D7896) and specific heat capacity testing (ASTM E1269). We perform ASTM D7583, the on-engine John Deere Engine Coolant Cavitation Test. Related testing includes:

- ASTM D8485 – Corrosion Test for Electric Vehicle Coolants

- ASTM E202M – Glycol Content

- FTM 2540C – Dissolved Solids in Coolant

- ASTM D7896 – Thermal Conductivity

- ASTM E1269 – Specific Heat Capacity

- ASTM D7583 – John Deere Cavitation Test

- ASTM D7304 - Determination of Denatonium Ion in Engine Coolant by HPLC