In the early 1980s, Southwest Research Institute worked with the diesel engine industry to meet new particulate emissions limits. Lacking expertise in emissions or aftertreatment technologies, manufacturers focused on improving combustion through engine design. Diesel filters, or diesel particulate traps, were developed as a possible “aftertreatment” solution. However, engine manufacturers, government and academia applied the technology with mixed results.

At about the same time, President Ronald Reagan signed the National Cooperative Research Act. Developed to promote innovation, facilitate trade and strengthen the competitiveness of the United States in world markets, the law limited the antitrust liability of joint research and development ventures. Ten days after the law passed in 1984, SwRI initiated its first multiclient cooperative research program, soliciting joint funding to develop precompetitive research into a consortium studying particulate filter regeneration mechanisms. SwRI was particularly well-positioned to run this consortium as an independent, nonprofit organization already serving government and industry in both the engine and emissions research and development space.

Various automotive consortia that followed initially addressed performance, emissions and fuel efficiency. Today, consortia are also evaluating battery technology and lubricants for electrified powertrains as focus shifts to decarbonizing the transportation sector. With that in mind, SwRI is hosting the inaugural Global Decarbonized Mobility Summit (GDMS) Nov. 13–17. The GDMS will assemble industry members from multiple automotive-related consortia and joint industry projects at SwRI’s San Antonio headquarters. Throughout the summit, SwRI staff experts will hold sessions on the latest research and development advancements, pathways for lowering emissions through decarbonization, and how the industry can meet the latest technology challenges associated with lowering greenhouse gas emissions.

The Global Decarbonized Mobility Summit will highlight a wide range of innovative research, developments and demonstrations of solutions currently happening. The Institute has a long history of guiding collaborative programs that help clients pool resources and funding, enabling SwRI’s next-generation research to reduce or eliminate emissions.

The summit will begin with regular project status meetings for automotive consortia members. On Nov. 14, GDMS will open to non-consortia members from automotive, transportation, manufacturing and other mobility sectors to learn about innovative decarbonization technologies. Programming will include expert-led sessions regarding SwRI internal research on the future of mobility as well as a campus tour.

Over the last 40 years, SwRI has run 23 consortia and joint industry programs with one focused on clean diesel engines reaching its ninth phase. Other consortia and joint industry programs featured in this focused issue of Technology Today include oil and gas exploration and production, aerospace safety software tools and industrial robot software cooperative research as well as the four automotive consortia that follow. Consortia are the best way to leverage limited R&D budgets for high risk/high reward future mobility solutions. And SwRI consortia benefit from a longstanding internally funded research program.

1. CHEDE: Clean Highly Efficient Decarbonized Engines

In 1991, SwRI launched the industry’s longest-running advanced engine research consortium. The successive clean diesel programs have resulted in a long history of cooperative research between SwRI and the diesel engine industry, eventually for light- and medium-duty applications as well. From the start, the program has pursued the world’s most efficient powertrain solutions to address existing and potential regulations and industry needs 10-plus years into the future. The latest four-year program continued the tradition, incorporating aggressive new efficiency, performance and emissions goals with a pivot toward hybrid-electric powertrains. Goals include research and demonstration of technologies to meet the world’s strictest emissions and fuel economy standards.

Exhaust emissions of particular concern are greenhouse gases and nitrogen oxides or NOx. NOx has direct harmful effects on human health and indirect effects on the environment and ecosystems. All gasoline and diesel internal combustion engines (ICEs) produce NOx. Reducing the pollutant is usually accomplished by minimizing combustion temperatures to produce less NOx and then using aftertreatment devices to react with it, breaking it down into less harmful constituents. Limiting NOx in diesel engines is particularly challenging. The heavy-duty powertrain emission goals for CHEDE-8 included more stringent goals than the Environmental Protection Agency’s anticipated greenhouse gas and NOx rules for model year 2027. CHEDE-8’s light-duty emissions goals aim for upcoming European NOx and CO2 standards. Building on more than 30 years of advanced engine research, the ninth phase of CHEDE will kick off on Nov. 15 with a new name, Clean Highly Efficient Decarbonized Engines (CHEDE-9), that reflects today’s goals in sustainable transportation.

Concentration

The CHEDE-8 Program Advisory Committee, consisting of consortium members, sets the focus on technologies to exceed future fuel economy and emissions regulations using electrified powertrains, particularly off-road and heavy equipment applications offering significant opportunities to integrate high-power-density engines with highly efficient motor and battery systems. The consortia looked for innovative ways to improve ICE efficiency through advanced combustion strategies, smokeless diesel combustion and novel aftertreatment integration methods. The team considered engine fundamental architecture, novel waste heat recovery systems and new operational approaches. To develop cost-effective light-duty diesel solutions, the consortium looked at diesel-hybrid electric powertrains, super-low emission solutions and CO2-minimized powertrains.

DETAIL

Brake thermal efficiency (BTE) indicates the fuel efficiency of internal combustion engines. The higher the brake thermal efficiency, the lower the fuel consumption and greenhouse gas emissions.

To create a clean hybrid-electric diesel engine powertrain, CHEDE-8 used advanced modeling and simulation technology to investigate innovative combustion systems and powertrain energy management. Additional strategies to improve efficiency while reducing emissions included advanced air and exhaust gas recirculation systems, waste heat recovery and advanced friction reduction methodologies. The team also looked at a systems approach to integrating various aftertreatment solutions to address the more challenging emissions reduction needs of diesel engines.

SwRI has extensive facilities and novel test capabilities to support hybrid electric diesel engine research, including 15L, 13L, 6.8L and 2.8L research engines as well as dedicated single-cylinder research engines. Laboratory facilities include an optical combustion visualization vessel, a high-pressure spray setup and bearing and liner friction test stands. SwRI also has a battery and advanced electronics laboratory as well as transmission and driveline evaluation facilities.

Accomplishments

Through CHEDE-8, SwRI designed three different hybrid diesel powertrains. The heavy-duty powertrain coupled a 13L engine with a 48-volt motor and electrified accessories. This powertrain would allow heavy-duty long-haul trucks of the future, increasing fuel economy by over 30% through better engine efficiency, optimized oil and coolant flow, and some energy recovery from braking. The medium-duty powertrain shrank the engine size using a high-voltage electrical system. For future vocational vehicles such as dump or garbage trucks, this powertrain could reduce fuel use by 40% and create an efficient plug-in hybrid medium-duty powertrain. Finally, the light-duty powertrain pursued a low-emissions plug-in hybrid concept, coupling a smaller diesel engine with an electrified axle to provide high fuel efficiency for future SUVs and light commercial vehicles.

CHEDE-9

As CHEDE-8 draws to a close, the next phase is starting with 2035 goals to reduce greenhouse gas emissions by 35–50% from 2024 model-year products while reducing tailpipe NOx to below 1 part per million. Transportation power concepts will be differentiated by access to energy and energy storage — power and range — requirements. When long range, high power and long durability are needed, CHEDE-9 will be adapting internal combustion engines to be the net-zero CO2 powertrain of the future.

CHEDE-9 is looking at the full range of duty cycles of light-, medium- and heavy-duty applications, identifying key strategies for each. For vehicles with low average power and daily range (~100 miles), the consortium is focusing on e-fuels and dual-fuel strategies. For vehicles with medium power and daily range requirements (~300 miles), the team is investigating hydrogen-powered internal combustion engines (H2-ICE) research. For applications requiring high average power and long daily range (~600+ miles), the consortia will investigate liquid-fueled or H2-ICE-based powertrains that use CO2-neutral (or better) fuel sources.

For more information about CHEDE, contact Chris Bitsis at +1 210 522 5509.

SwRI developed single-cylinder research engines to efficiently evaluate new engine concepts.

SwRI maintains extensive engine development and test facilities to support advanced diesel engine research.

2. HEDGE®: High-Efficiency Dilute Gasoline Engine

SwRI has extensive facilities to support H2 engine research, including five engine test cells outfitted with light-duty, medium-duty and heavy-duty hydrogen supercharged engines and fuel cell equipment. As an outgrowth of advanced engine research, SwRI has launched an H2-ICE consortium to explore engine applications for this carbon-neutral fuel.

SwRI launched the HEDGE consortium in 2005 with the goal of improving gasoline engine efficiency for light- and heavy-duty vehicle applications. At the time, engineers anticipated that the Environmental Protection Agency’s post-2010 emissions goals would limit efficiency and cost advantages diesel engines had over their gasoline counterparts. One of the main impediments to improving gasoline engine efficiency is engine knock, a violent, uncontrolled combustion event characterized by a knocking or pinging sound generated as pressure waves resonate through the engine.

DETAIL

Engine knock occurs when fuel burns unevenly in an engine cylinder, causing knocking or a pinging sound, which can ultimately damage engine components.

History

The consortium organizers sought to mitigate knock by reintroducing a portion of the engine’s exhaust products back into combustion chamber. They proposed that exhaust gas recirculation (EGR) would reduce knock through a phenomenon called charge dilution. The extra, largely inert exhaust gas molecules displace oxygen in the combustion chamber, effectively slowing the chemical chain reactions that lead to engine knock. They convinced several well-known OEM and supplier companies to cooperatively fund research into this unique new concept, and the High-Efficiency Dilute Gasoline Engine (HEDGE) consortium was born.

Succession

This first iteration of the HEDGE consortium successfully demonstrated that combining cooled EGR with advanced sparkignition technology significantly improved engine fuel efficiency by reducing knock, allowing operation at improved combustion phasing and higher compression ratios. The gasoline engines in the HEDGE consortium achieved fuel consumption rates that were equal to or better than similar diesel engines.

Upon completion of its original four-year schedule, sufficient interest in continuing the research led to the HEDGE II consortium, which kicked off in 2009, continuing its focus on high levels of EGR combined with supporting technologies such as turbocharging, advanced charge motion, high-energy ignition, etc. Every four years a new consortium commences, each building on the learning and success of the previous program, until the present day where the HEDGE-V consortium continues, which includes many members of the original HEDGE group.

Accomplishments

DETAIL

Direct-injection engines atomize fuel using high pressures to spray fuel directly into the spark plug area to ignite combustion.

Over the last 18 years, most major automotive manufacturers and Tier I suppliers have participated in the consortium. Nearly every hybrid-electric car today has an engine inspired by the HEDGE program. Cooled EGR effectively mitigates other forms of destructive abnormal combustion such as Low-Speed Preignition or LSPI. Other notable HEDGE developments include the invention of the patented Dedicated-EGR (D-EGR) concept, which enhances the properties of EGR with partially burned rich combustion products, and the SwRI-patented Dual Coil Offset (DCO) technology, which greatly increases the energy delivered by the sparkplug without the damaging effects of high-energy ignition systems. This long-running program has served to significantly strengthen SwRI’s relationship with critical OEM clients and continues to spark (pun intended) new and innovative ideas for single-client projects.

For more information about the current HEDGE-V consortium, contact Ryan Williams at +1 210 522 5185.

SwRI developed an air handling system for a client to improve fuel consumption and regulate emissions, applying HEDGE-developed technology to a production-level product.

SwRI engineers incorporated their DCO and D-EGR engine technologies into a demonstration vehicle to establish the improved fuel economy and reduced exhaust emissions achieved. Both of these technologies were recognized by R&D Magazine as among the 100 most significant technological achievements introduced in 2011 and 2014, respectively.

3. EVESE: Electrified Vehicle and Energy Storage Evaluation

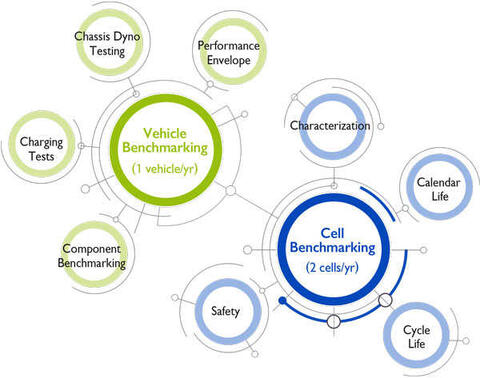

In 2020, SwRI formed the EVESE consortium as a continuation of the Energy Storage System Evaluation and Safety (ESSES-I and ESSES-II) consortium launched in 2011. Initial goals included helping vehicle manufacturers and battery suppliers develop precompetitive, detailed cell-level test data on electrochemical storage systems and performing research to advance testing methodologies to evaluate batteries. Staff members designed the consortium to provide transparency in the automotive battery market to advance global development of energy storage systems.

Electric powertrains offer several operational advantages over traditional powertrains, but they also present several unique challenges, notably a steep sticker price and “range anxiety” — concern that an EV will run out of power before reaching its destination or a suitable charging point.

Concentration

The mission of SwRI’s EVESE consortium is to provide analysis and evaluation of current electrified vehicle technologies and conduct research focused on improving the efficiency, performance, safety and cost to improve adoption of electrified powertrains. To facilitate the transition to electrified vehicles, state agencies are working with the private sector to develop affordable fueling and charging options. In addition, most vehicle manufacturers have made a commitment to selling a majority of electrified vehicles as soon as 2030 to 2040. With these commitments, understanding state-of-the-art technologies for lithium-ion batteries, electric motors and electrified vehicles is crucial.

SwRI’s EVESE consortium analyzes current electrified vehicle technologies to improve the efficiency, performance, safety and cost of these technologies, including lithium-ion battery and vehicle/component benchmarking.

Initially the ESSES consortium focused on vehicle and component benchmarking, particularly the lithium-ion battery packs dominating the market. Engineers developed test systems to ensure the performance and safety of EV technology, particularly the battery packs. SwRI used internal research funding to understand critical failure modes, developing techniques to simulate and physically test thermal, structural and crash failures, investing a tremendous amount of capital in its battery test laboratory. The facility can simulate multiple environments, altitudes, and shake and vibration scenarios. To address battery safety, engineers have designed tests to evaluate different materials between the cells, evaluating both the structural and energy propagation effects through the pack, as well as how heat propagates between cells.

Structural deformation that could occur in a crash can be simulated at crush test facilities for individual cells and full packs. SwRI ballistics experts evaluate battery response to fire and projectiles impinging the pack and how to mitigate damage in these scenarios. SwRI’s anechoic chambers support battery electromagnetic interference and compatibility testing.

Accomplishments

With benchmarking and safety testing protocols in place, the team turned to more advanced research subjects, including studying different battery designs and chemistries to find the most cost-effective package.

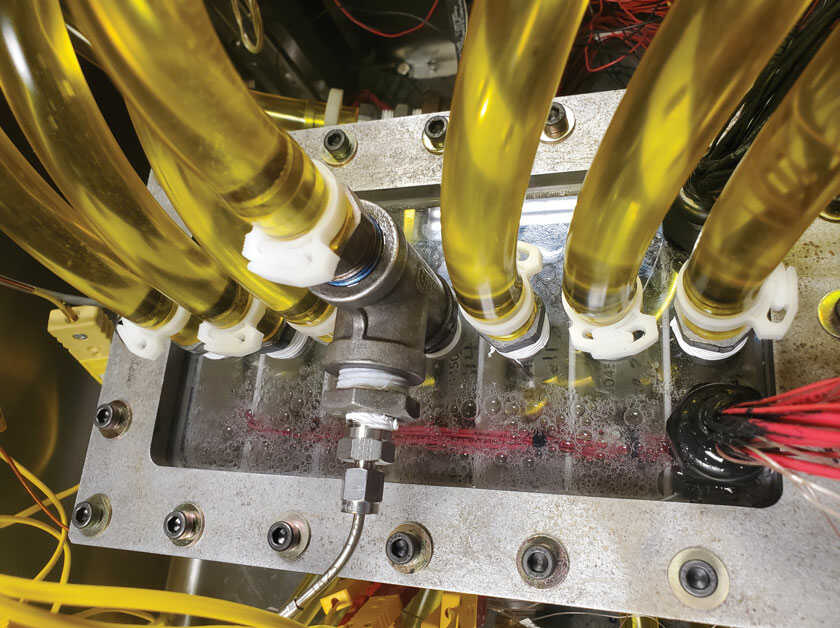

A complementary Grid-Connected Battery Energy Storage Systems consortium was established, and both consortia studied new solutions to limit battery degradation while decreasing battery recharge times. Engineers developed a real-time controller to monitor lithium plating during fast-charging events and adjust the charge current accordingly. The goal is to charge the battery at the optimal limit of its ability to intercalate, or absorb, the lithium ions into the anode, but no faster. This rate is changeable and inconsistent, varying with the state-of-charge of the battery and environmental conditions, so the controller must continually adjust the charging rate in real time. The SwRI controller increased the charging by 30% with significantly reduced degradation over manufacturers’ recommended fast-charging strategies. The consortia are also investigating lithium plating diagnostics and novel safety technologies, along with new thermal management protocols, particularly during aggressive charging and discharging events. New immersive cooling techniques using liquids that conduct heat, but not electricity in direct contact with the battery, can improve thermal management. These systems conduct 50 to 100 times more heat than conventional indirect cooling solutions.

For more information about EVESE, contact Andre Swarts at +1 210 522 2041.

SwRI conducts range and efficiency testing on electric trucks using its all-wheel-drive chassis dynamometer.

SwRI developed a flow rig to study the impact of direct immersion cooling on battery cell performance and aging.

4. AFEV: Advanced Fluids for Electrified Vehicles

In 2021, SwRI launched the AFEV consortium to advance the industry’s understanding of the unique stressors placed on electric vehicle (EV) and hybrid vehicle fluids. The consortium seeks fluid solutions for next-generation vehicles, advancing and optimizing EV fluids or e-fluids and powertrain design.

Concentration

As electric vehicles push speeds and power levels higher, understanding the role of lubricants in protecting hardware and delivering desired performance is critical. Initial topic areas for AFEV center around lubricant performance criteria necessary to properly protect and enhance operations of electrified powertrains. In any automotive application, lubricants and hardware must work together. The environment inside electric vehicles is unique when compared to conventional powertrains.

Lubricants and hardware work together to form a complete system, and as hardware evolves, lubricant requirements also change. Electrified vehicle fluids place a stronger importance on heat transfer properties, corrosion resistance, electrical conductivity and performance under high-speed conditions. Various new architectures and designs under development may require a different emphasis on fluid performance.

To improve performance and cost, AFEV will characterize new materials, higher input speeds, larger gear reductions and electrical considerations to help lubricant formulators develop the best fluids and hardware suppliers create advanced designs. Understanding EV fluid performance and developing methods to assess it are critical in determining how fluid formulations will affect the overall system.

SwRI’s AFEV consortium is combining its expertise in powertrain development with extensive experience characterizing fuels and lubricants to target electric vehicle fluids, or e-fluids.

Important performance metrics for e-fluids include how well they protect hardware at high speeds relative to traditional automotive applications and optimized heat transfer performance to keep motors operating at peak efficiency. Aeration and compatibility with materials unfamiliar to automotive fluids are also important characteristics. The electrical properties of e-fluids must be understood and balanced for safe, optimized performance. Lubricants also affect overall drivetrain efficiency, important for improving the range of EVs. E-fluid testing is an emerging field of study in the lubrication industry, and the Advanced Fluids for Electrified Vehicles consortium is performing the fundamental research needed to develop tests relevant for electric vehicles.

For more information about the AFEV consortium, contact Peter Morgan at +1 210 522 3143.