CHEDE-9

Building on more than 32 years of the industry’s longest running commercial vehicle research consortium, the Clean Highly Efficient Decarbonized Engines 9 (CHEDE-9) consortium will begin in January 2024. We renamed the consortia from Clean Hybrid Electric Diesel Engines to reflect the expansion of decarbonization research into diesel and other internal combustion engines.

The consortium will focus on low- and net-zero carbon dioxide (CO2) transportation technologies for both heavy-duty commercial and light-duty passenger vehicles. CHEDE-9 will use a holistic approach including low-carbon intensity fuels, advanced engine and powertrain systems, and life-cycle analyses.

Program goals include developing decarbonized Powertrain Solutions for 2035 and beyond:

- GHG 35-50% below 2024 products

- Tailpipe NOx below 1ppm (parts per million)

Areas of Concentration

- Decarbonized Engines and Fuels

The path towards decarbonization requires both optimized engines and fuels. High-efficiency engines will ensure a maximum of fuel energy is converted into useful work. Meanwhile, fuels research will be conducted to determine the optimal balance of performance, energy density, infrastructure and sustainability. - Zero Parts Per Million Aftertreatment

The proposed CARB 2027 NOx limit for heavy-duty vehicles requires an average tailpipe NOx of less than 3 ppm. CHEDE-9 seeks to develop aftertreatment solutions that reduce NOx below this level, with a stretch goal of 100 ppb (parts per billion).

Visit our Membership Details page to learn more.

Specific CHEDE-9 Research Areas

- Advanced modeling and simulation

- ZEV ICE

- Next-generation combustion systems including direct-injection — spark ignited (DI-SI) and compression ignition (CI) combustion

- Hydrogen ICE-specific zero-PPM aftertreatment

- Ammonia and NH3/H2 blend combustion development

- Net-Zero ICE

- Zero net carbon liquid fuel combustion development

- Spark-ignited (SI) e-fuels

- Compression-ignition (CI) renewable fuels (Methanol/Ethanol/DME)

- Fleet Decarbonization

- Synthetic fuel sensing and control optimization

- Powertrain optimization for renweable diesel (HVO)

- Zero net carbon liquid fuel combustion development

- Advanced hybridization and electrification

- Innovative combustion systems

- Life cycle analysis for low carbon fuels

On-Site CHEDE-9 Facilities

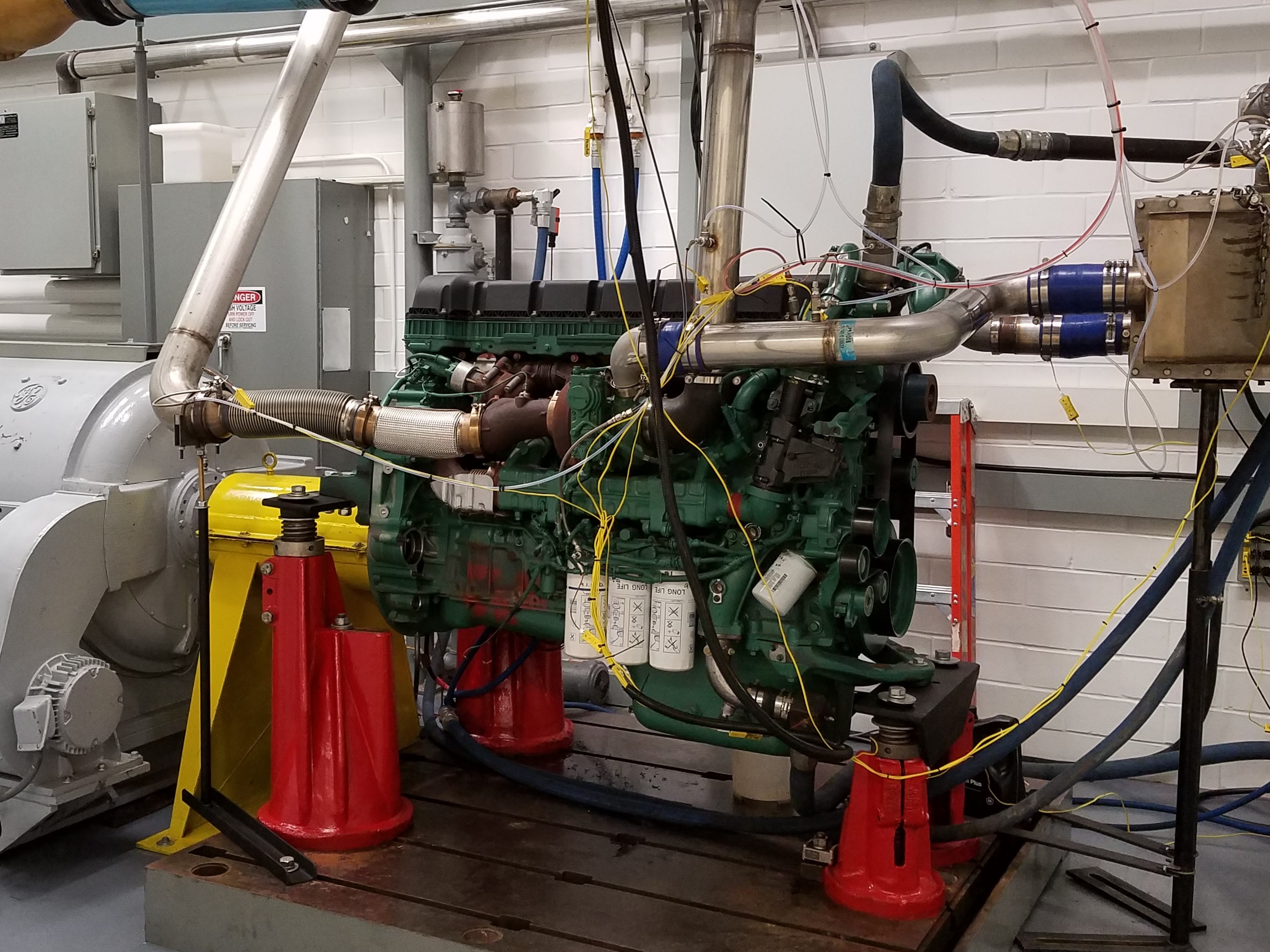

- Multiple research engines available

- Single cylinder, 2.8L, 6.8L, 13L, 15L

- 65,000L cryogenic hydrogen storage tank

- Optical combustion vessel

- High-pressure spray laboratory

- Bearing friction laboratory

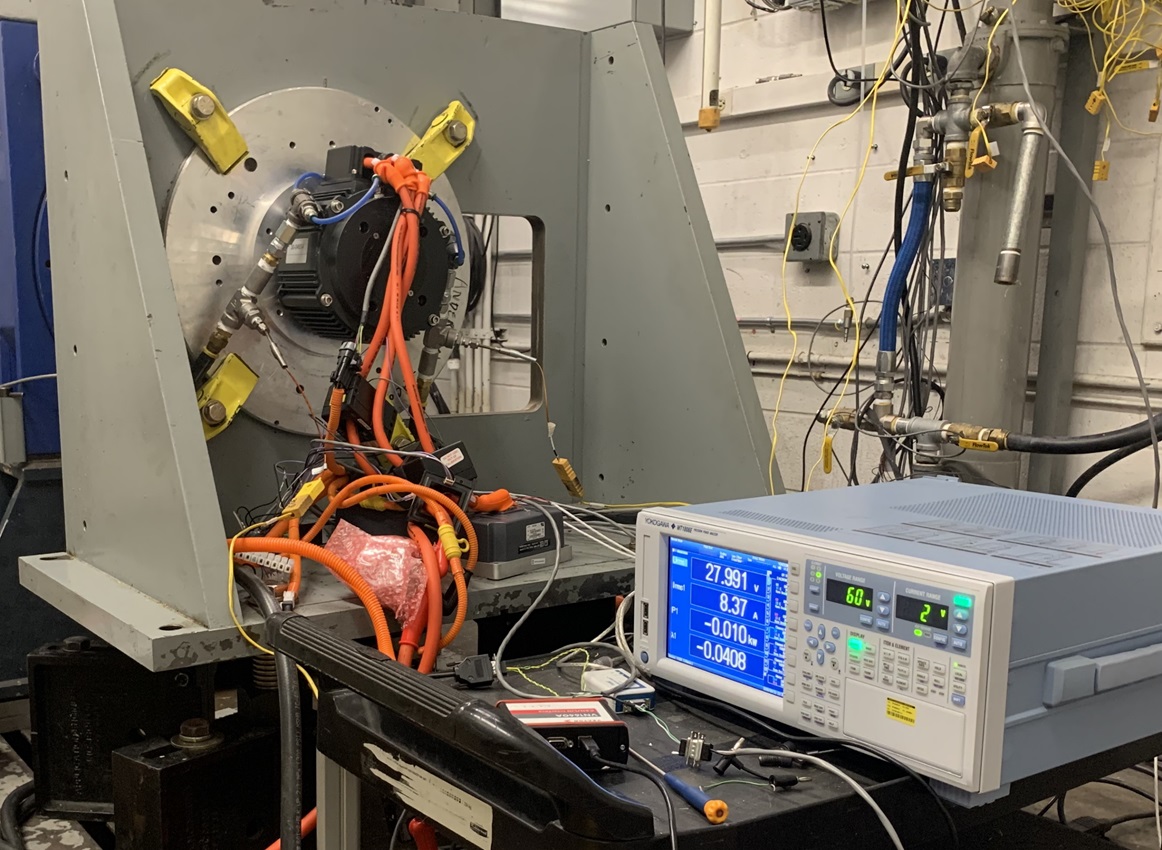

- Battery and advanced electronics laboratory

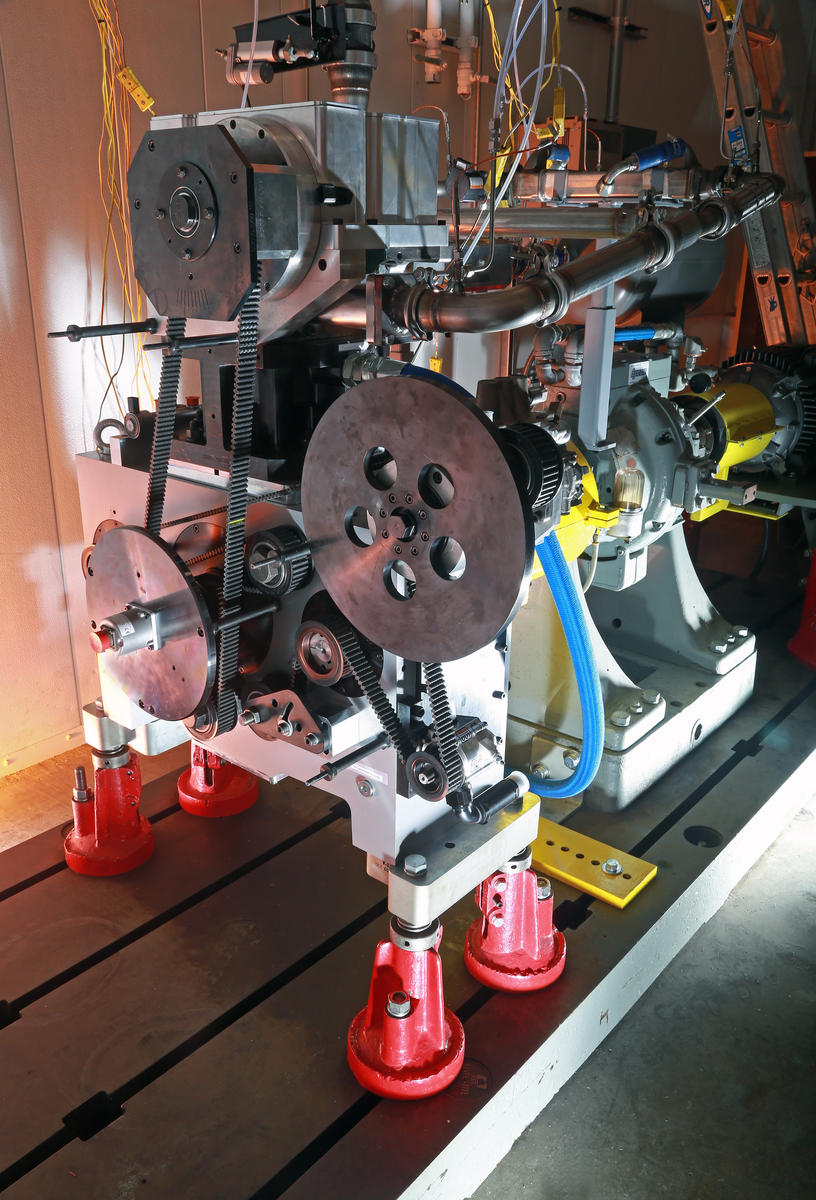

- Transmission and driveline evaluation facilities

Upcoming Events

- CHEDE-9 Spring PAC Meeting, March 25-26, 2024 (closed session for members only)

- CHEDE-9 Fall PAC Meeting, October 28-29, 2024 (closed session for members only)