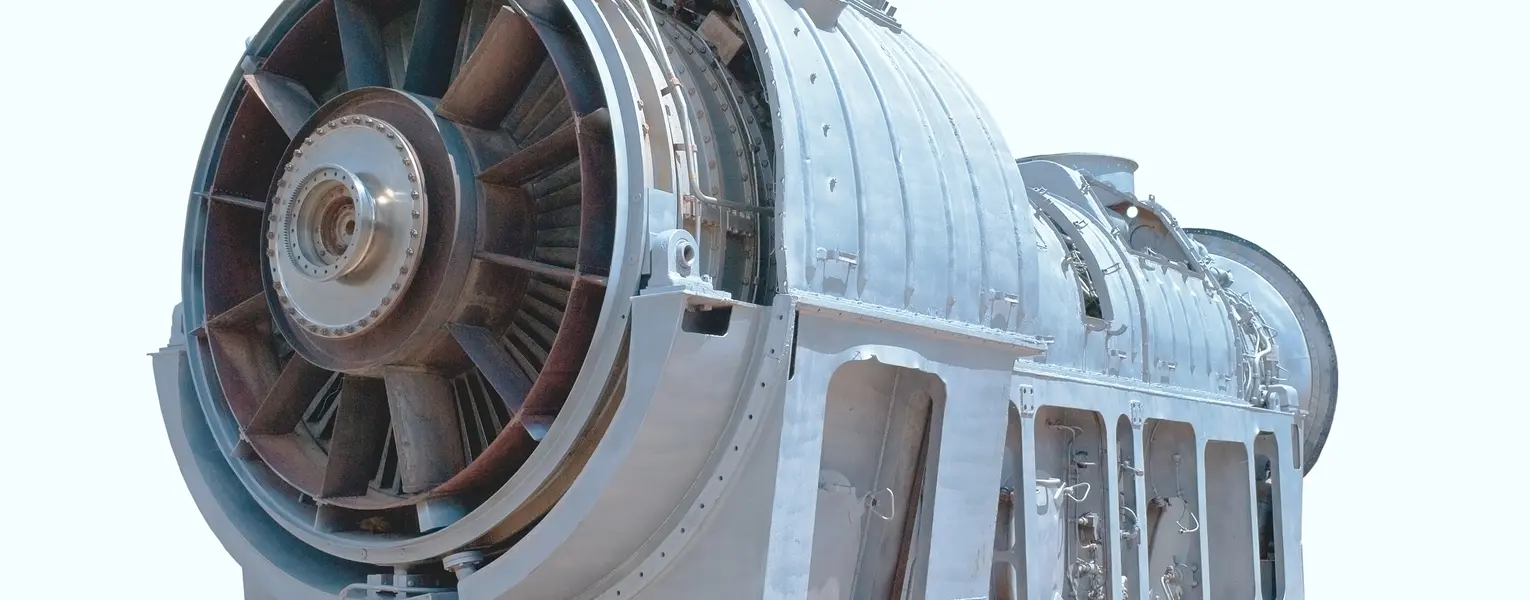

The gas turbine industry continually challenges engineers to design, construct, and operate reliable and efficient gas turbines that meet market needs and respect the environment. Southwest Research Institute (SwRI) provides technical services, expertise, and research facilities to meet the challenges of:

- Gas Turbine Users

- Gas Turbine Suppliers

- Gas Turbine Manufacturers

Gas turbines are a versatile, cost-effective source of electricity, mechanical power, and propulsion. Gas turbines continually challenge engineers to design, construct, and operate reliable and efficient turbines that meet market needs and respect the environment. SwRI works with users, suppliers, and manufacturers of gas turbines, providing technical services, expertise, and research facilities to meet the challenge.

Gas Turbine Engineering Capabilities

A complete list of gas turbine engineering capabilities is available online.

- Root Cause Failure Analysis: Blading, bearings, combustors, and other gas turbine components. Investigations combine the technologies of fractographic examination, materials evaluation, structural analysis, dynamic loading, thermal environment prediction, fracture mechanics analysis, and frequency testing.

- Troubleshooting Turbomachinery Operating & Installation Problems: Vibration problem diagnosis, monitoring systems and surveys, resonance identification, flow-induced vibration (exhaust ducts, HRSG, combustors), blade vibratory stress prediction, rotating machinery diagnosis, installation and commissioning support, rotor balancing, and third-party evaluation.

- Turbomachinery Performance Diagnosis: Diagnosis of fuel flow measurement accuracy, performance measurement methods and results, power output, and heat rate. Meter audits and high accuracy Flow Meter Calibrations Services. Heat rate improvement studies, waste heat recovery analyses, and fluid mechanics and heat transfer analyses.

- Rotordynamic and Mechanical Design Audits: Design audit services help both original equipment manufacturers (OEMs) and end-users avoid severe vibrations and other damaging dynamic phenomena in machinery installations.

- Mechanical Design Assurance: Rotor dynamics analysis (lateral/torsional/instability), pulsation control, FEA and CFD analyses, probabilistic evaluation, design recommendations. Design consultation and technical representation. Optimization and system integration for specialty applications of turbines and turbo-compressors.

- Aero-Thermal Flow Analysis: Fluid dynamics and heat transfer, simulation and understanding of fluid flows, flow visualization techniques, flow facilities, turbomachinery test facility, flow instability.

- Materials and Coatings Selection: Selection and qualification of alternative materials and coatings, supplier qualification, refurbishment evaluation.

- Procurement Support: Basic specification writing, review, and technical bid evaluations, purchase management, bid tab comparisons.

- Blade Vibration Audit Technology: Diagnostic methods to detect and avoid high-cycle-fatigue damage, blade frequency audit, blade modal analysis, blade vibratory stress audit, probabilistic analysis, nonintrusive monitoring, telemetry testing, and slip ring systems.

- Gas Turbine Inlet Filtration Services: SwRI Machinery Department engineers can assist you with your gas turbine inlet filtration challenges.

- Life Analysis & Management: Several life management and extension (LM&E) studies for hot section components of various turbines are performed at SwRI.

- Root Cause Machinery Failure Analysis: Multidisciplinary investigations are conducted at SwRI to determine the root cause of failures and provide corrective action guidance.

SwRI can offer you a full range of capabilities and experience in gas turbine technology including becoming an extension of your engineering department.

Contact us for more information about our gas turbine technology capabilities, or how you can contract with SwRI.

For more information, contact Griffin Beck or call +1 210 522 2509.