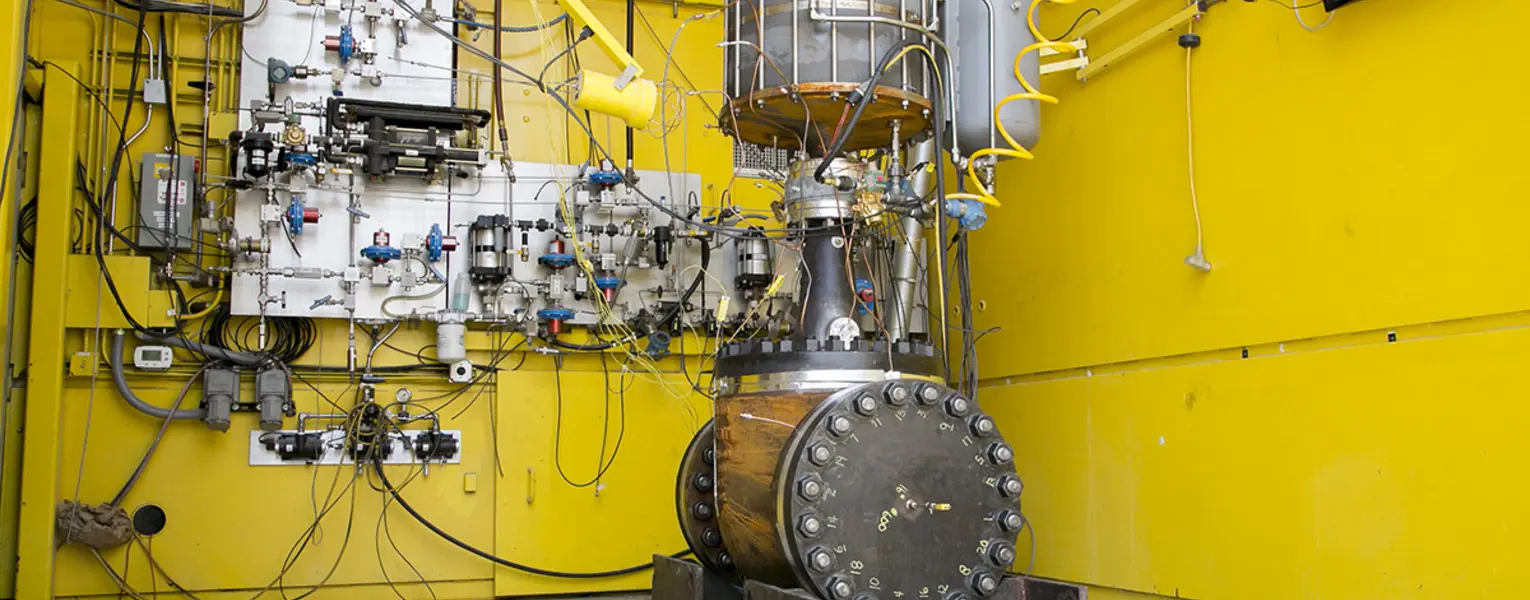

Testing the pressure integrity and sealing ability of valves is critical for industrial applications. If these potential leak points are not identified, operators can experience lost inventory, fines for broken regulations, safety hazards, and negative environmental impacts. Validating the pressure and sealing integrity of valves prior to installation will significantly reduce these risks. SwRI provides standardized valve integrity and cryogenic testing to qualify valves based on industry-accepted leak rates for external and internal sealing elements.

Valve Integrity Qualification Testing for the Oil, Natural Gas, Power Generation, and Petrochemical Industries

Valve integrity testing can be performed with liquid or gas, at pressures up to 35,000 psig, and valve sizes from ¼ inch to >24 inch. SwRI’s valve test capabilities include the following standardized test procedures:

- MSS-SP-61 – Pressure Testing of Valves

- API 598 – Valve Inspection and Testing

- ANSI FCI 70-2 – Control Valve Seat Leakage

- ISO 5208 – Industrial Valves - Pressure Testing of Metallic Valves

- Custom test procedures can be accommodated based on the project requirements

Cryogenic Test for Valves

Performing a cryogenic test for valves and other products used in the oil and gas industry may entail full immersion in liquid nitrogen immersion (-320°F). SwRI performs cryogenic testing to meet standardized tests or design and fabricate custom test chambers, including:

- BS 6364 – Specification for Valves for Cryogenic Service

Related Services

- Methane Leak Detection

- Custom Flow Loop Design

- Valve and Flow Component Testing

- Flow Component Testing

For more information about valve integrity and cryogenic testing, please contact Christopher Jowers at +1 210 522 4221.