Performance testing of gas lift valves is needed to verify valve operation and measure flow capacity. Achieving field-like pressure conditions is crucial for accurate testing. Southwest Research Institute (SwRI) replicates these conditions using existing infrastructure including the Nitrogen Blowdown Facility, high-pressure test cells, low-pressure water flow loops, and the Gas Lift Test Facility (GLTF).

Flow Coefficient & Dynamic Performance Testing

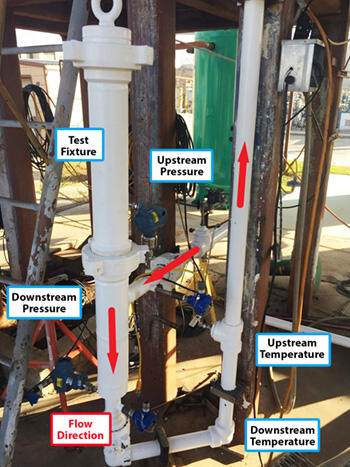

Figure 1. Gas Lift Test Section for testing per API 19G2, Annex G.

We perform testing per API 19G2, Annex G in the Nitrogen Blowdown Facility for test pressures less than 3,000 psi.

- Gas Lift Test Section (Figure 1) – The gas lift test section within the Nitrogen Blowdown Facility comprises a fully instrumented mandrel-style fixture that can accommodate gas lift valves of various sizes.

- Flow Coefficient Testing (Figure 2) – API 19G2, Annex G testing at the Nitrogen Blowdown Facility has automated upstream and downstream control valves that allow the operator to maintain approximately constant upstream pressure while decreasing the downstream pressure and increasing flow through the test article. This functionality allows the operator to perform testing per API 19G2, Annex G.

Broad Range Testing Capabilities

Figure 2. Flow Coefficient Testing per API 19 G2, Annex G.

For flow testing at harsher conditions, the Gas Lift Test Facility (GLTF) has a broader range of capabilities including:

- Flow rates in the range of approximately 0.2 to 15 MMScfd (million standard cubic feet/day)

- Upstream pressure controlled up to approximately 10,000 psig

- Differential pressures over 2,500 psi

- Temperatures up to 180ºF and 275ºF

- Gas specific gravity of 0.55 – 0.97

Full-scale Gas Flow Test

The GLTF was designed to perform the full-scale gas flow test (per API 19G2, Section H.9 for the V0 validation grade) at especially harsh conditions. The test includes in-situ back-check integrity testing, flow performance testing in stepped flow rate increments, automated valve cycling, and long-duration continuous flow testing.

For recirculating flow testing at lower pressures and temperatures, the High-Pressure Loop at the Metering Research Facility is a recirculating natural gas flow loop capable of upstream pressures up to 1,100 psi and flow rates up to 200 MMscfd with a maximum differential pressure across the test article around 110 psid.

Gas-Lift Test Facility

SwRI’s Gas Lift Test Facility performs validation and performance testing on gas-lift valves using dry gas. The facility performs API 19G2 VO testing and mimics harsh downhole conditions with high temperature and pressure.

Back-check Testing & Bellows Actuation Lifecycle Testing

The rest of the back-check testing (per API 19G2, Annex H) as well as other static pressure testing, such as bellows actuation lifecycle testing (per API 19G2, Annex J), are performed in one of two high-pressure test cells. The test cells are equipped to supply high pressure nitrogen gas or water to a custom-made test stand. Application of pressure is applied remotely for safety. These capabilities include:

- Nitrogen, water, or oil pressures up to 30,000 psi

- Test temperature control from cryogenic to 400ºF

- Custom gas lift valve test stands accommodate up to 3 valves simultaneously

Figure 3. Backflow Integrity test per API 19G2, Annex H.

Backflow Integrity Test at Elevated Temperature

Heating or cooling of the stands is performed locally using an insulated enclosure (Figure 3) with an environmental control unit, a convection oven, heat trace, or exposure to chilled water or liquid nitrogen. This specific setup allowed the operator to perform Backflow Integrity Testing per API 19G2, Annex H at both maximum rated temperature and pressure within one of SwRI’s test cells.

Liquid flow testing, such as erosion testing (per API 19G2, Annex K) and other custom flow tests are performed at the Flow Component Testing Facilities. All testing is performed with calibrated instrumentation.

For more information about gas lift testing, please contact Nicole Lemon at +1 210 522 3329.