Automotive & Transportation

About the Header

For over 40 years, SwRI has conducted extensive fuel surveys, procuring and analyzing thousands of samples from filling stations around the world.

Southwest Research Institute’s engines, fuels and lubricants research, development and evaluation services have been refined, improved and expanded since the Institute’s earliest days. As leaders in automotive and transportation initiatives, SwRI staff members are well versed in low-carbon technologies as well as traditional internal combustion engines. This breadth of expertise positions SwRI to meet the needs of its diverse client base, while continuing to upgrade its technology and testing capabilities to meet current and future industry demands. SwRI also brings technology solutions to mobility challenges in the intelligent transportation arena.

Automotive

SwRI pioneers research, development and evaluation options for aftertreatment system technologies, helping the automotive industry meet and exceed emissions and fuel efficiency standards. Many of today’s diesel engines use selective catalytic reduction (SCR), an advanced emissions control system, to abate oxides of nitrogen (NOx) emissions. Diesel exhaust fluids (DEFs) — mixtures of urea, water and additives — are injected into the exhaust stream, to ideally decompose and form ammonia to react with NOx on the SCR materials to form nitrogen and water.

Currently, new automotive fluids must undergo strict “no-harm” testing to ensure that these products do not have negative effects on engine performance or hardware. SwRI is developing new DEF testing methods for advanced aftertreatment systems. As the only organization in the country that conducts this research, SwRI is providing input to the American Petroleum Institute to update standards designed to test and qualify DEFs.

In addition, SwRI has licensed its R&D 100 Award-winning catalyzed DEF, or Cat-DEF™, to reduce NOx and carbon dioxide emissions while minimizing undesirable deposit formation in exhaust systems. The licensing agreement allows a manufacturer to develop products using patented SwRI DEF technology, which incorporates catalysts and surfactants into diesel exhaust fluid to improve performance. Cat-DEF is backward compatible with existing engines, reducing deposit formation by 90%. The product could allow diesel engine manufacturers to pass stringent testing without expensive engine hardware modifications.

SwRI has licensed its R&D 100 Award-winning Cat-DEF technology to reduce NOx and carbon dioxide emissions while also minimizing undesirable deposit formation in exhaust systems, as tested on the simulated system above.

SwRI will soon manage a client-installed grid storage installation on our campus to support design, development, production, testing and innovation for the energy sector.

SwRI also has extensive experience providing performance and abuse testing for batteries, cells and packs as well as grid-scale energy storage systems. We are now applying that expertise to provide battery pack production and design services. SwRI’s battery testing and research team will work with clients to design and create custom battery packs to meet special needs and ensure performance. Our facilities in Ann Arbor, Michigan, serve as a leading benchmarking facility for electric vehicles.

Grid-scale storage can involve large-scale battery systems to store energy and balance supply and demand, and Texas has the second largest grid installation base in the country. SwRI is preparing to manage a client-installed grid storage system on our campus to support this burgeoning industry. This commercial collaboration allows SwRI to better understand battery-electric storage system software controls and operating cycles. This opportunity will provide enabling expertise to design, develop, produce and test innovative technology for the grid sector. SwRI is currently pursuing research to develop its own unique battery system software.

SwRI’s emissions testing continues to advance and will be particularly relevant as the international industry expects stricter standards that will affect testing, particularly for NOx emissions. As emissions standards become more stringent around the world, SwRI remains well-positioned to provide robust, professional and extensive emissions evaluation capabilities to ensure compliance. In addition, most U.S. engine manufacturers will need to produce engines able to meet standards for the international market, so the parts, electronics, fuels and lubricants for those engines will continue to need testing.

SwRI provides battery production and design services that integrate and complement our longstanding performance and abuse testing of batteries, cells and packs as well as grid-scale energy storage systems.

As global emissions standards become more stringent, SwRI continues to offer robust, professional and extensive capabilities to ensure engines, fuels and lubricants meet criteria.

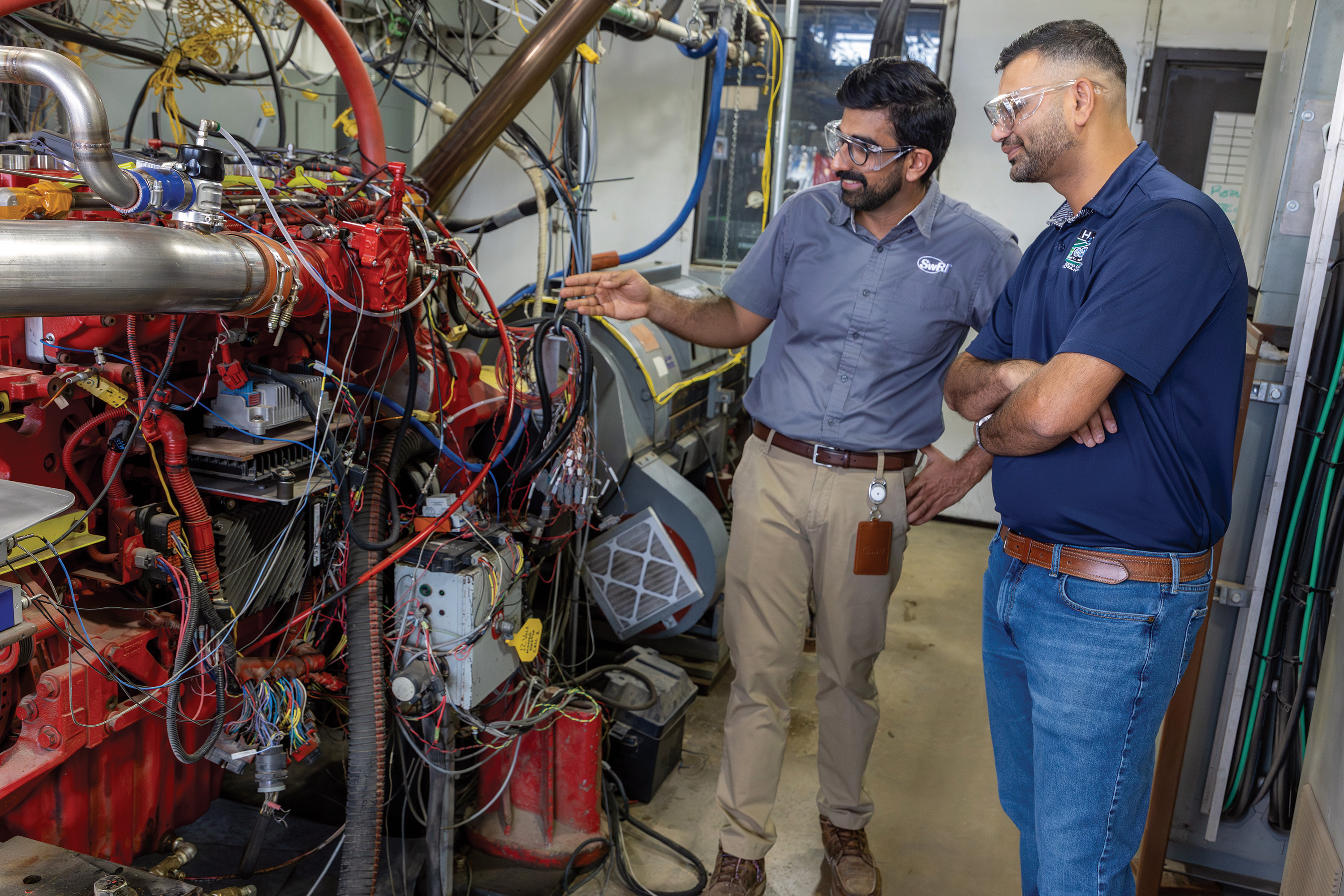

SwRI is collaborating with The University of Texas at San Antonio to create technology to detect and identify pre-ignition in hydrogen internal combustion engines (H2-ICE). Researchers will combine machine learning algorithms and artificial intelligence with onboard sensors to detect pre-ignition and related conditions. SwRI has been spearheading efforts to develop H2-ICE for industry use through its many consortia, such as Clean Highly Efficient Decarbonized Engines (CHEDE). These efforts have led to advancements in systems research and other successes, such as SwRI’s fully functional H2-ICE class 8 truck.

SwRI successfully completed an ambitious eight-year project that demonstrated how connected and automated vehicle technology and SAE Level 4 automation could accomplish 30% energy savings over traditional hybrids, without modifications to the powertrain hardware. The Advanced Research Projects Agency–Energy’s (ARPA–E) NEXTCAR (NEXT-Generation Energy Technologies for Connected and Automated On-Road Vehicles) program funded the research. SwRI showcased its technology at the NEXTCAR program’s capstone event at the American Center for Mobility in Michigan in June. The award-winning “Eco-Mobility with Connected Powertrains” technology suite and Phase II developments are now available to license. The project’s team now looks toward adapting and innovating the algorithms for automotive and other technology, including drones, aviation and more.

An engine co-developed by SwRI recently won a 2025 R&D 100 Award. The “Low Mass and High Efficiency Engine for Medium- Duty Truck Applications” was recognized by R&D World Magazine as one of the year’s 100 most significant innovations. SwRI supported the multiyear development of a medium-duty truck engine capable of yielding a 10% increase in fuel economy and a 15% weight reduction using advanced materials and combustion technologies. The project was funded by the U.S. Department of Energy Vehicle Technology Office and led by General Motors.

In 2025, SwRI successfully completed an eight-year project that demonstrated how connected and automated vehicle technology and SAE Level 4 automation could accomplish 30% energy savings over traditional hybrids, without modifications to the powertrain hardware.

SwRI is collaborating with the University of Texas at San Antonio to create a detection system to identify pre-ignition in hydrogen internal combustion engines, such as this heavy-duty engine that SwRI demonstrated last year.

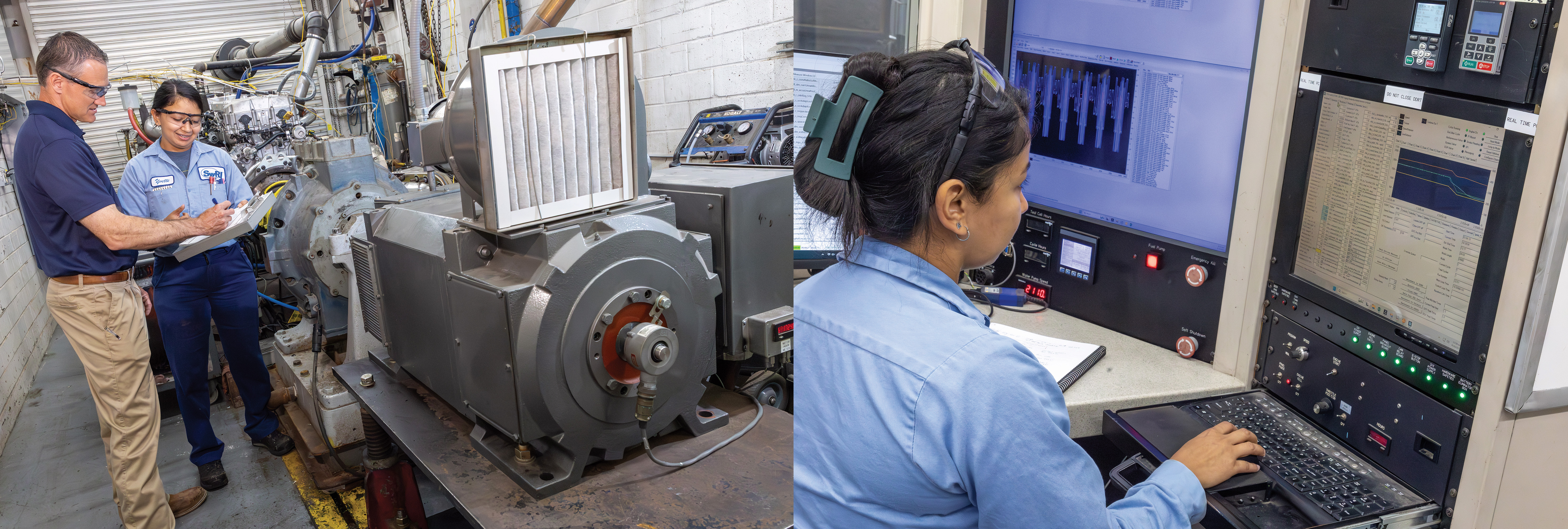

SwRI is preparing new heavy-duty engine oil specification tests in response to the U.S. Environmental Protection Agency’s 2027 emissions rules, currently known as Proposed Category 12 or PC-12. These oils are designed to have lower viscosity and better thermal resistance to improve fuel economy globally. We are helping manufacturers ensure that the new low-viscosity formulations avoid excessive engine component wear associated with inadequate lubrication. SwRI is developing new standardized test specifications, adapting and enhancing existing tests while developing innovative hardware to use less fuel to lower development and evaluation costs.

SwRI has developed a new test for pre-ignition in internal combustion engines, focusing on how fuel affects pre-ignition. This uncontrolled combustion in an engine is associated with several variables. Similar tests exist to examine lubricant effects; however, engine manufacturers are interested in the different ways fuels might contribute to the phenomenon to help prevent it.

SwRI operates 24 “road simulators,” conducting rapid, cost-effective, round-the-clock mileage accumulation at speeds up to 100 miles per hour. These chassis dynamometers accommodate most cars and light trucks up to 7,000 pounds, conducting any transient or steady-state driving cycle. One of our dynamometers offers four-wheel-drive capabilities and supports hybrid vehicle testing under real-world conditions. Four newly installed dynamometers have temperature- and humidity-controlled engine inlet air to ensure consistent operating conditions year-round. An additional high-performance dynamometer supports vehicles up to 400 horsepower.

Upgrades to AC dynamometers used to simulate fleet testing now recover power for SwRI's grid instead of sending waste heat to cooling towers that consume water, saving SwRI thousands of dollars a year in electricity.

Recent upgrades to AC dynamometers also reduced our carbon footprint by generating power for SwRI’s grid instead of sending waste heat to cooling towers that consume water. Three dynamometers, which often run 24/7 for days on end to support automotive testing services, now produce enough energy to save SwRI thousands of dollars a year. A fourth system will go online next year.

In 2025, SwRI supported Shell Eco-Marathon events worldwide in Indianapolis, Poland and Qatar. These annual events invite high school and university student teams from across the globe to design, build and race ultra-high-efficiency vehicles at famous racetracks. For nearly 15 years, SwRI has supported the Shell Eco-Marathon, which included sponsoring the Off-Track Award for Technical Innovation. Each year, our staff provide assistance and expertise for the student competitors and helps conduct technical and engineering inspections.

SwRI staff members support Shell Eco-Marathons around the world, providing assistance and expertise for the student competitors and helping conduct technical and engineering inspections of their ultrahigh-efficiency vehicles.

Transportation

For more than 30 years, SwRI has been a premier provider of intelligent transportation systems (ITS) and advanced traffic management systems (ATMS) for state and local agencies. These networks integrate infrastructure, technology and software with vehicles to communicate with the traveling public. SwRI’s ITS technology is deployed across several states, serving more than 25% of the United States population to enhance safety and mobility.

SwRI has developed an ITS showcase laboratory allowing engineers to test and demonstrate software for transportation infrastructure, signs and cameras before roadway deployment.

An SwRI-led team is developing and deploying the Data Exchange Platform for Operational Technologies (DEPOT) for the Florida Department of Transportation (FDOT). This cutting-edge system enhances statewide data collection, analysis and dissemination capabilities, to create a fully integrated solution that prioritizes mobility and safety. The system will enable FDOT to disseminate connected and automated vehicle information to the automobile industry, logistics providers and other third parties to consume for their specific applications.

Over the last three years, SwRI has developed a production version of the DEPOT system for Pennsylvania to inform motorists about work zone closures and impacts. Other states working to integrate DEPOT include New Hampshire, Vermont, Maine, Georgia and California as well as the North Central Texas Council of Governments.

District 2 of FDOT is the first agency to implement SwRI’s Active-Vision™ camera analytics system. This technology uses machine vision and learning to pinpoint critical incidents like wrong-way drivers and traffic accidents across 18 counties in Northeastern Florida.

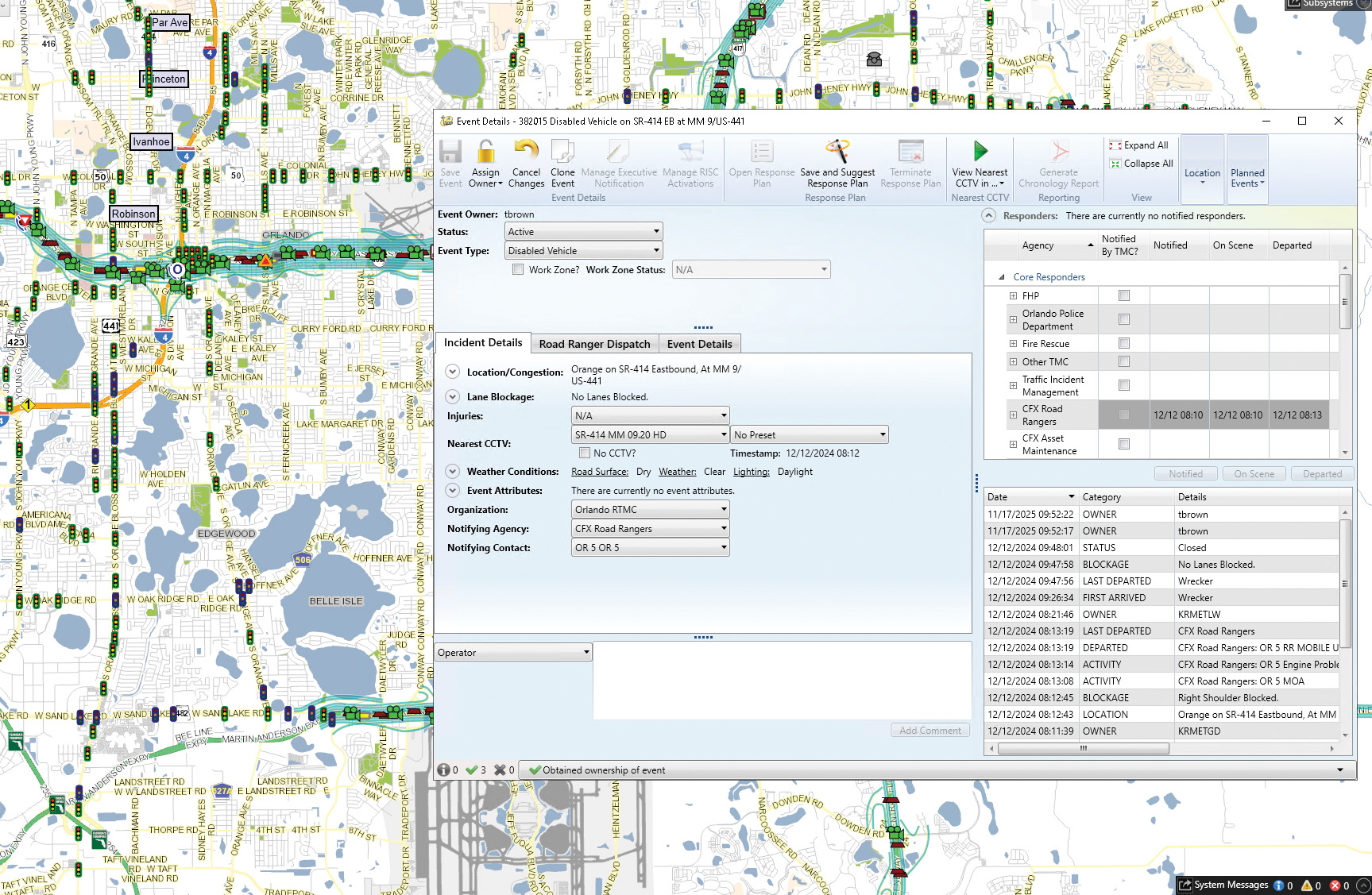

We customized, installed and launched SwRI’s ActiveITS™ ATMS for the city of Seattle. The resulting traffic operation center enhances situational awareness, traffic signal integration and seamless data sharing between the center and emergency services, key partners and the Washington State Department of Transportation.

In 2025, SwRI also integrated a traffic prediction modeling tool in Virginia. By incorporating AI and data-driven insights, this system empowers traffic engineers to more effectively manage traffic incidents and congestion.

SwRI customized its ActiveITS system in Seattle for our first deployment at a city level — most ITS solutions are managed by state agencies. Here, the user interface shows road equipment deployments and a sample incident.