Deeper wells containing hydrogen sulfide, also known as sour wells, are being explored by the oil and gas industry. The combination of higher pressure and temperature as a result of the wells’ depth and acidity due to the presence of hydrogen sulfide (H2S) make those wells particularly challenging when it comes to materials. As a result, the industry uses expensive corrosion resistant alloys during exploration and production. The alloys are qualified using combinations of documented field experience and laboratory testing, but a recent review of the chemistry of sour wells suggest that the environmental test conditions are harsher than required. The goal of the Sour Measurements in Autoclave for Reliable Thermodynamic Calculations (SMART Calc) is to help the industry save millions of dollars on the alloys used to withstand the well conditions.

Joint Industry Project, Phase 1

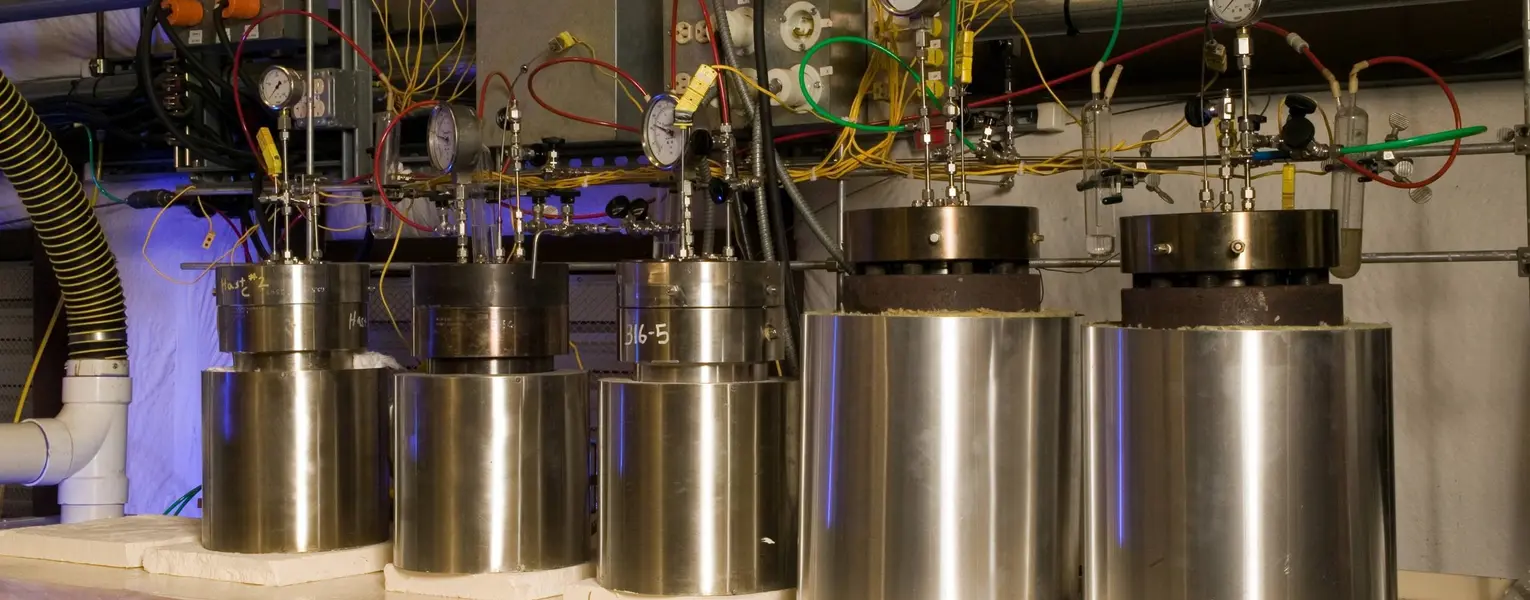

During the 1-year first phase of this JIP, an experimental matrix will be generated at the intersection of the industry needs, model limitations, and lack of data, and the in situ analytical techniques will be validated. SwRI will also recreate the conditions of the sour wells in collaboration with OLI Systems Inc., who will contribute modeling expertise.

Joint Industry Project, Phase 2

During the second phase, in situ H2S measurements will be performed over the experimental matrix. The results from those measurements will be implemented in the modeling software to offer a more accurate and reliable model of the conditions of sour wells. This will in turn be used to reduce the need for expensive materials.

Membership

To inquire about membership, contact Dr. Florent Bocher.