Hydraulic fluid is widely used in varied equipment such as tractors and excavators, brakes, transmission systems, power steering systems, industrial machinery and more. SwRI offers a variety of performance and research services to help develop hydraulic fluids and to evaluate them to determine performance properties. SwRI provides a number of hydraulic fluid tests and tractor hydraulic fluid tests.

Conestoga Pump Test (ASTM D7043)

The Conestoga Pump Test, or ASTM D7043), runs a Conestoga B1 vane pump at 1,200 rpm, 13.8 MPa (2000 psi), and 66°C for 100 hr. with 18.9 liters of fluid to determine anti-wear characteristics of a fluid. Performance is measured by measuring weight loss of the pump’s vanes and cam ring. A V104C pump was formerly used; the internal components of the Conestoga pump mimic the V104C pump.

ISO20763 Pump Test

The ISO20763 Pump test determines anti-wear characteristics of a fluid by running a Conestoga B1 vane pump at 1,440 rpm and 13.8 MPa (2000 psi) for 250 hr. with 70 liters of fluid. The inlet temperature is determined by the temperature at which the fluid has a viscosity of 13mm2/s (anhydrous fluids) or 30mm2/s (aqueous fluids). Performance is measured by measuring weight loss of the pump’s vanes and cam ring.

DIN 51389-2 Vane Pump Wear Test

SwRI conducts a Vane Pump Wear Test to determine the anti-wear properties of hydraulic fluids. The fluid is pumped by an electric-driven vane pump for 250 hours at an inlet temperature selected to maintain a kinematic viscosity of 13 mm2/sec. The pump components are weighed before and after the test. Weight loss determines the fluid performance. The ISO 20763 test procedure has absorbed this procedure and is now operationally the same.

Eaton 35VQ25A Pump Test

Anti-wear characteristics of a fluid are determined by running a 35VQ25A vane pump at 2400 rpm, 207 bar (3000 psi), and 95°C for 50 hr. with 190 liters of fluid. Performance is measured by measuring weight loss of the pump’s vanes and cam ring. A fluid must pass the first 3 runs or four of five runs.

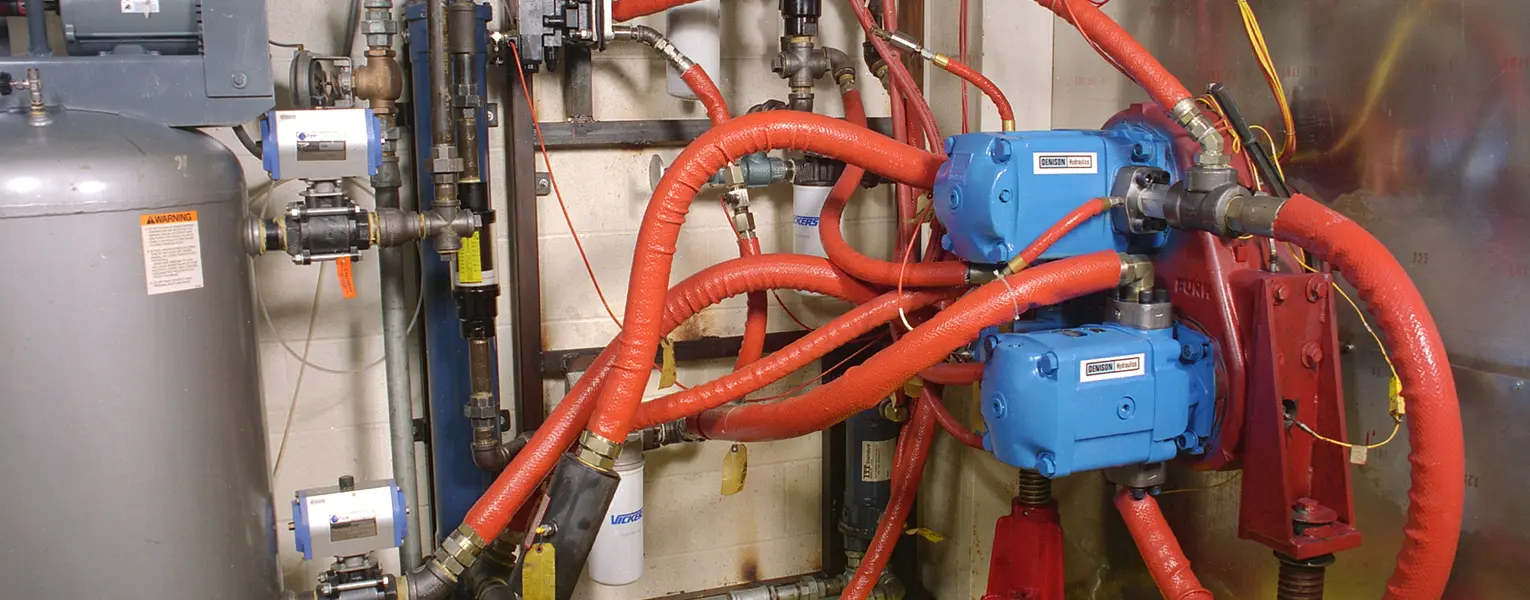

Denison T6H20C Hybrid Pump

These Parker Denison tests evaluate fluid performance and anti-wear characteristics in a hybrid T6H vane and piston pump. The tests are broken into a dry (no water added) testing phase and wet (water added) testing phase. The vane and piston pump are cycled to near rated conditions every two seconds. Each phase is a little over 300 hours long each.

For questions about this testing, please contact Michael Charron at +1 210 522 6632.