SwRI designed the Workbench for Offline Robotics Development™ (SWORD™) software for manufacturing engineers and robotics developers. This user-friendly graphical toolkit integrates ROS programming with CAD features, including joint movement mockups on an industrial robot.

For decades, the tedious nature of robotics programming and significant capital costs presented an economic barrier to widespread adoption of industrial automation. High development and deployment costs meant industrial robots were largely bolted down in huge factories and limited to rote operations such as low-mix, high-volume assembly line welding and other manufacturing tasks.

In recent years, industrial robotics have evolved to work beyond the safety “cage,” allowing people and machines to operate collaboratively, taking advantage of mobile, agile technology. Today’s automation ecosystem requires novel applications of robotic arms, mobile platforms and even integrated drones.

Unlocking tomorrow’s industrial automation requires complex setups and component programming, which slows development time and poses challenges for modern robotics integrators. More software and more moving parts require more engineers who need more training to continuously improve, sustain and grow their investments.

Southwest Research Institute plays an important role in this ever-evolving ecosystem by developing code, offering education and supporting the ROS-Industrial project, which applies open-source robot operating system (ROS) software to the manufacturing industry. The ROS-I platform supports open-source, interoperable solutions for academia, government and industry. As the United States seeks to reshore manufacturing, investments in automation will play a key role in competing on a global stage. SwRI is proud to offer automation solutions that help our clients gain competitive advantages.

SwRI demonstrates the complexity of modern robotics using a mobile platform outfitted with a robotic arm.

DETAIL

SwRI launched the ROS-Industrial open-source project in 2012 in collaboration with Yaskawa Motoman Robotics and Willow Garage to springboard the use of open-source robot operating system software to automate manufacturing. The Institute maintains the ROS-I software repository and leads the ROS-Industrial Consortium Americas in cooperation with counterparts in Europe and Asia.

Graphical Toolkit

DETAIL

FreeCAD is an open-source parametric 3D modeler to design real-life objects of any size. Modifications are simple, achieved by changing parameters in the model history.

Building on its robotics experience, SwRI’s Intelligent Systems Division developed a new toolkit that integrates several robotics solutions into one intuitive interface. The SwRI Workbench for Offline Robotics Development™ (SWORD™) is designed to demystify programming for new users and speed up the development process for advanced integrators. SWORD is a plugin for the FreeCAD application, allowing manufacturing engineers to leverage computer-aided design applications within a familiar graphical interface while unlocking powerful tools within the ROS codebase.

SWORD users create and evaluate unified robotics description formats (left) and set up motion planning pipelines (right) to conduct testing and evaluation. When it’s time to execute a task, SWORD allows users to export a variety of file types, such as URDF, SRDF, Tesseract and native robot programs.

Historically, robotics integration required extensive experience in mechanical engineering, electrical engineering or computer science. Developers translate abstract concepts into code and machine learning algorithms to enable manipulators to move various end effectors or tools along a process path to get a job done.

The traditional ROS-Industrial workflow is software-programming-intense, requiring developers who are deeply familiar with programming languages and software code libraries to build interactive systems. Even experienced developers within the ROS-I ecosystem and beyond may spend significant time — weeks or months — on the initial setup and configuration of a ROS application.

SWORD cuts that time to days by efficiently integrating tasks into core sections focused on building the environment, programming parts, validating accuracy and producing results.

Listening to ROS developers, diverse stakeholders and consortium members, the development team recognized requirements for easier access to ROS-I motion planning tools, while maintaining a connection to the CAD ecosystem where the products in process are conceived and maintained.

Environmental Modeling

Before an industrial robot can begin to paint, weld or handle materials, developers model its physical environment in 3D to ensure a safe, collision-free workspace. SWORD allows users to create 3D models of robots and floor space by importing CAD images of hardware and work cells into the software. The modeling features allow users to unlock advanced digital twin capabilities to simulate and test their systems before, during and after production.

DETAIL

A digital twin is a virtual representation of a physical object, system or process synchronized with its real-world counterpart.

SWORD’s environment modeling tools allow users to create or import CAD models of robots, including fixtures and end-of-arm tooling. It features joint sliders for manipulating and simulating movement using multiple inverse kinematics solvers. This mathematical process calculates the joint parameters needed to move the end effector to a specific position and orientation.

SWORD models the robot workspace using a set of operational points, mapped using convex hulls. A convex hull represents the smallest polygon that contains every point, like a rubber band wrapped around a structure. Convex hull decomposition breaks down non-convex shapes, such as a polygon with indentations, into smaller convex shapes. SWORD uses convex hulls and convex hull decomposition to flexibly create simplified geometries that produce the collision matrices for visualization testing.

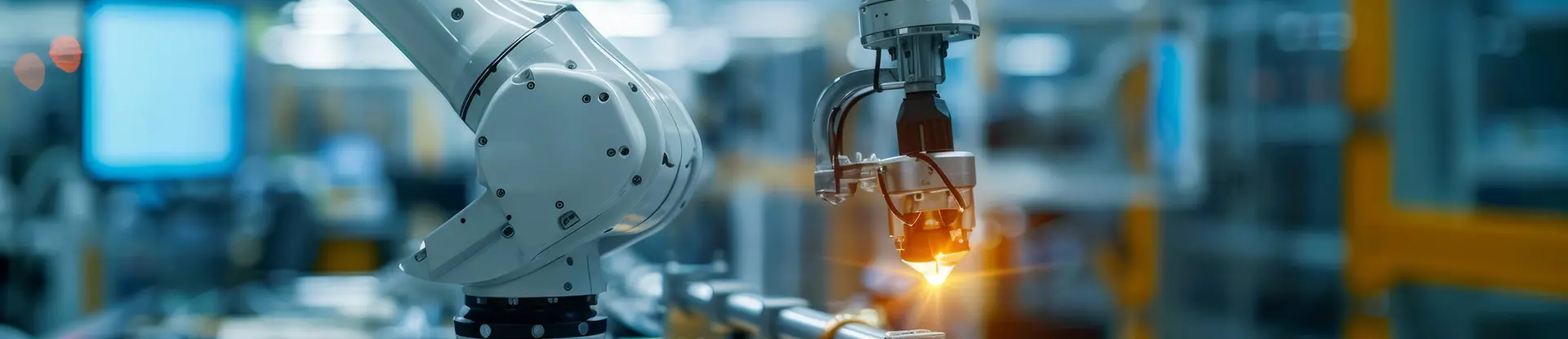

Using SWORD, engineers configured the setup and operations of this robotic welding application quickly and efficiently, integrating tasks into core sections focused on building the environment, programming parts, validating accuracy and producing results.

Manipulation & Planning

Motion planning shows a robot how to move in a work cell considering space and time constraints. Robot manipulation integrates tools, or end effectors, to perform a given task. ROS-Industrial offers a vast library of open-source tools that enable manipulation and motion planning. Tools include Scan-N-Plan to enable trajectory planning from 3D scans, Tesseract to provide kinematics data on mechanical movement, and TrajOpt to optimize robot trajectories.

DETAIL

Unified robotics description format (URDF) files create real-time 3D visualizations of robots.

SWORD allows users to generate motion plans using open-source and commercial path planners, creating custom pipelines for application-specific behavior while predicting and avoiding collisions. Users can configure motion, define motion groups, configure inverse kinematic solvers and use a Cartesian tool center point dragger to define how the robot interacts in its environment using X, Y and Z coordinates. They can also plan motion, generate waypoints, configure motion planners and visualize trajectories to examine a planned path step-by-step to ensure it is safe and feasible.

Cartesian waypoints are segments of the pathway that specify a robot’s position and movement in a workspace defined by X, Y and Z coordinates. SWORD allows users to define robot motion using Cartesian or joint waypoints, specify different segment movements and insert supplementary commands such as integrated on/off tool control and delays.

Launch

SwRI develops robotics solutions for clients while supporting the ROS-Industrial project by managing software repositories, conducting robotics training and organizing events.

SwRI developed SWORD over two years through its Internal Research and Development program. The team launched SWORD in spring 2024 and has integrated the toolkit into SwRI projects while training interested clients.

Tools like SWORD will be vital for integrating emerging technology into existing workspaces. As part of its strategic roadmap, SwRI has developed a plan to add new features regularly and looks forward to sharing the power of SWORD and ROS-Industrial with new users.

Questions about this story or SWORD? Contact Matt Robinson at +1 210 522 5823. To inquire about a trial license or a guided tour, please visit https://sword.swri.org or listen to Matt Robinson and Michael Ripperger discuss SWORD on the Technology Today Podcast.

ABOUT THE AUTHOR

Matt Robinson manages the ROS-Industrial Joint Industry Project, which advances open-source robotics capabilities to deliver solutions for industrial applications. His expertise includes manufacturing value stream design and optimization, non-ferrous metallurgy and materials processing and automating processes.