Energy & Environment

About the Header

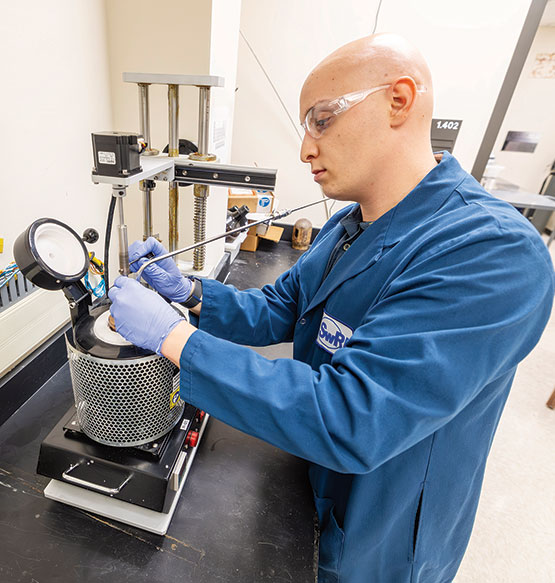

SwRI developed a fluidized bed pilot plant that can produce 2.3 tons of clean hydrogen a year. Operating at commercial temperatures, chemists are identifying solutions for solids transport and tackling challenges related to scale-up and product quality.

Since its founding in 1947, Southwest Research Institute has supported the energy industry in a wide range of capacities. In 2025, the program remained active in developing sustainable industrial processes while also advancing conventional energy technology. SwRI continues to support safety for the nuclear power, oil and gas production, and solar energy industries.

A new 90,000-square-foot Machinery Innovation Center for High-Energy Fluids is under construction at SwRI. It will facilitate megawatt-scale testing of machinery such as gas turbines, turbo compressors, reciprocating compressors, industrial heat pumps and many other systems that use these hydrocarbons and other flammable gases in power generation or conversion applications. It will also allow researchers to evaluate a range of hydrocarbon machinery for efficiency, safety and durability.

Surging use of artificial intelligence applications is exponentially increasing demands for high-speed computing that produce massive amounts of heat. This is driving dramatic increases in the demand for high-capacity heat exchangers that efficiently transfer heat between two or more fluids without mixing — used for a wide variety of heating and cooling applications. To meet burgeoning demands, SwRI is expanding its heat exchanger testing capabilities to include megawatt-scale performance evaluations, a capability matched by only a handful of facilities worldwide. Customizable testing facilities support a wide range of heat exchangers — from 500 kilowatts up to 2.75 megawatts in its current configuration, with the potential to exceed 5 megawatts — to help the industry establish a performance baseline for data centers.

Using IR&D funding, chemical engineers developed a lab-scale process to convert carbon dioxide (CO2) captured from industrial waste into graphene. With a wide range of uses from biomedical devices to sensors and electronics, graphene is both versatile and valuable. SwRI performed technoeconomic analyses to demonstrate the scalability of using a continuously stirred tank reactor to convert CO2 into graphene.

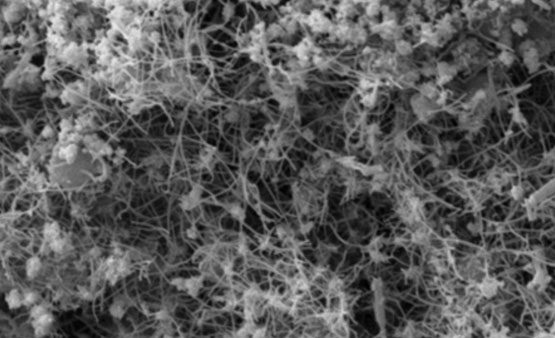

In 2025, SwRI engineers also demonstrated multiple pilot-scale conversion processes designed to produce clean energy and value-added carbon products from natural gas. This effort included the construction, commissioning and operation of several first-of-their kind pyrolysis demonstration plants that convert methane into hydrogen and solid carbon co-products such as graphite, carbon nanotubes and carbon black. SwRI chemical engineers advanced the field by developing the largest single-reactor process in the U.S. to produce carbon nanotubes at scale.

Peak shaving facilities stabilize energy supplies and pricing during periods of high demand by storing LNG in massive cryogenic tanks during periods of low usage. SwRI is evaluating how the potential introduction of hydrogen into these systems could affect safety.

SwRI developed processes designed to produce clean energy and value-added carbon products from natural gas. Using novel pyrolysis techniques, chemists converted methane into hydrogen and solid carbon co-products such as graphite.

SwRI evaluated flame spread between photovoltaic solar panels and roof materials, presenting the results at the National Fire Protection Association Conference. A second round of testing starts in early 2026.

In 2025, SwRI chemists demonstrated multiple pilot-scale conversion processes designed to produce clean energy and value-added carbon products from natural gas, such as these carbon nanotubes shown under an electron scanning microscope.

To support decarbonization efforts set by the aviation industry, chemical engineers performed internal research to produce sustainable aviation fuels (SAF) from electrofuels, or E-fuels, made from CO2 and hydrogen. A multidisciplinary team at SwRI then characterized the SAF to ensure it met all required specifications before combusting it in a custom jet engine test stand to gather emissions and particulate data. Chemical engineers also worked with clients to develop a process for converting fats, oils and greases into SAF precursors using new and existing fluidized and fixed bed reactors. These processes could help the aviation industry achieve its goal of exclusive SAF use by 2050.

SwRI has developed a fluidized bed pilot plant that can produce 2.3 tons of clean hydrogen a year. The facility demonstrated circulating and bubbling bed capabilities that ran continuously for thousands of hours. Operating at commercial conditions, SwRI is identifying solutions for solids transport and tackling challenges related to scale-up and product quality. These advancements will help support the chemical and petroleum industries and address feasibility issues surrounding clean hydrogen and carbon capture.

Power cycles that use supercritical carbon dioxide (sCO2) as the working fluid have the potential to yield higher thermal efficiencies at lower capital costs. SwRI conducts materials and machinery research to support these new power cycles. This year, engineers set new temperature records for testing materials in high-pressure environments. The team evaluated high-pressure, high-temperature sCO2 turbine materials at the unprecedented conditions of 1,150 degrees Celsius (2,100 degrees Fahrenheit) at 300 bar (4,350 psi). These are the highest published temperature and pressure conditions ever reached in sCO2 materials testing.

SwRI is investigating challenges associated with introducing renewable natural gas (RNG), a sustainable energy source. Transporting RNG, particularly from landfill sources, via the natural gas distribution network can introduce trace chemicals typically not found in geologic natural gas. SwRI has generated scientific test data to help inform operations and regulations pertaining to allowable levels of mercury in natural gas distribution systems as RNG is brought into the gas supply, ensuring that RNG is safe, reliable and properly regulated.

To meet surging demands for high-capacity heat exchangers, SwRI expanded our testing capabilities to address a significant market gap for equipment providing high-heat transfer rates involving high-temperature and -flowrate applications.

In collaboration with NYSEARCH, a nonprofit research and development organization for the gas industry serving utility members across North America, SwRI is investigating how blending hydrogen into liquid natural gas (LNG) could affect the integrity of LNG storage tanks. Natural gas is widely used to power appliances and heat homes. By blending hydrogen into these existing natural gas streams, utilities can reduce the carbon footprint of energy delivery while leveraging current natural gas infrastructure.

The Center for Nuclear Waste Regulatory Analyses (CNWRA®) continues to support the U.S. Nuclear Regulatory Commission (NRC) with expertise and research. The CNWRA performs technical and regulatory analyses to address the challenges of storing, transporting, processing, recycling and disposing of spent nuclear fuels. To support this work, the CNWRA organized a three-day international forum focused on research, technical and regulatory considerations to manage spent fuels for advanced nuclear reactors. In 2025, the CNWRA supported the license application review for proposed advanced nuclear power reactor sites in Wyoming and Texas, including analyzing the seismic hazards and structural engineering of proposed sites. Additionally, CNWRA conducted research to support updates to the NRC’s regulatory review process for spent advanced nuclear fuels.

In support of the Finnish Radiation and Nuclear Safety Authority, CNWRA staff evaluated the Safety Case for the Operating License Application for a deep geologic repository for spent nuclear fuel, currently under construction next to the Olkiluoto Nuclear Power Plant.

Also in 2025, SwRI performed a series of large-scale fire tests to investigate flame spread between photovoltaic (PV) solar panels and roof assemblies — the largest array tested to date. Baseline testing with three different PV panel racking orientations identified the design that promoted the fastest flame spread. We then tested two fire mitigation strategies — uncovered walkway and vertical barriers — with that racking orientation. All tests exposed the leading edge of the deck to flames and crosswinds, conditions that compare with related industry standards. Test results quantified fire hazards and mitigation strategies, providing critical data to builders, insurance groups and emergency responders.

Chemical engineers are developing processes to convert carbon dioxide captured from industrial waste into graphene. This versatile and valuable material is used in everything from biomedical devices to sensors and electronics.

SwRI developed processes to support sustainable aviation fuel production to help the aviation industry achieve goals of exclusive SAF use by 2050.