Advanced combustion research for power and propulsion aims at optimizing combustion processes to enhance efficiency, performance, and environmental sustainability of power generation and propulsion systems.

Southwest Research Institute (SwRI) helps government and industry research and develop advanced combustion technology, turbomachinery and industrial combustion systems. Our combustion expertise includes air-breathing natural gas, hydrogen, ammonia, oxy-fuel for supercritical carbon dioxide (sCO2) and aviation systems, as well as more unconventional systems such as rotating detonation engines and industrial burners. Our capabilities include:

- Design and implementation of combustion systems

- Experimental investigation

- Computational fluid dynamics simulation of combustion systems

- Design and implementation of control and monitoring systems

- Optical and non-optical diagnostics

- Emissions measurements system design and implementation

- Design and implementation of laser ignition systems

Combustion Test Facilities

SwRI offers several combustion turbine test facilities to investigate applications related to different combustion systems. With decades of experience assessing and improving power generation equipment, SwRI is a leader in combustion for advanced power systems, including the design, analysis, prototype fabrication and testing of combustion systems for turbomachinery and more advanced power generation and propulsion systems from kilowatt-scale to utility-scale.

Air compressor for combustion R&D.

Jet engine emissions and performance testing.

Gas turbine test facility.

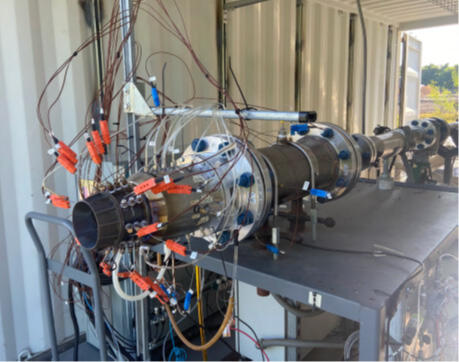

150 kW thermal oxy-fuel combustor test

High Energy Annex Test (HEAT) – This facility investigates gas turbine combustion up to 12 MW of thermal power. Air is delivered to the facility by a large compressor that can achieve flow rates up to 14 lbm/s and pressure up to 300 psig. The air is also pre-heated by a 1.9 MW electric heater. A sophisticated fuel delivery system provides up to four different fuels to the test articles. Natural gas, hydrogen and ammonia can be considered.

Jet Engine Research Facility – This facility investigates engine performance and emissions for jet engines. Currently designed for Pratt & Whitney JT15D engines, it can be used to test a variety of fuels for Sustainable Aviation Fuel Research.

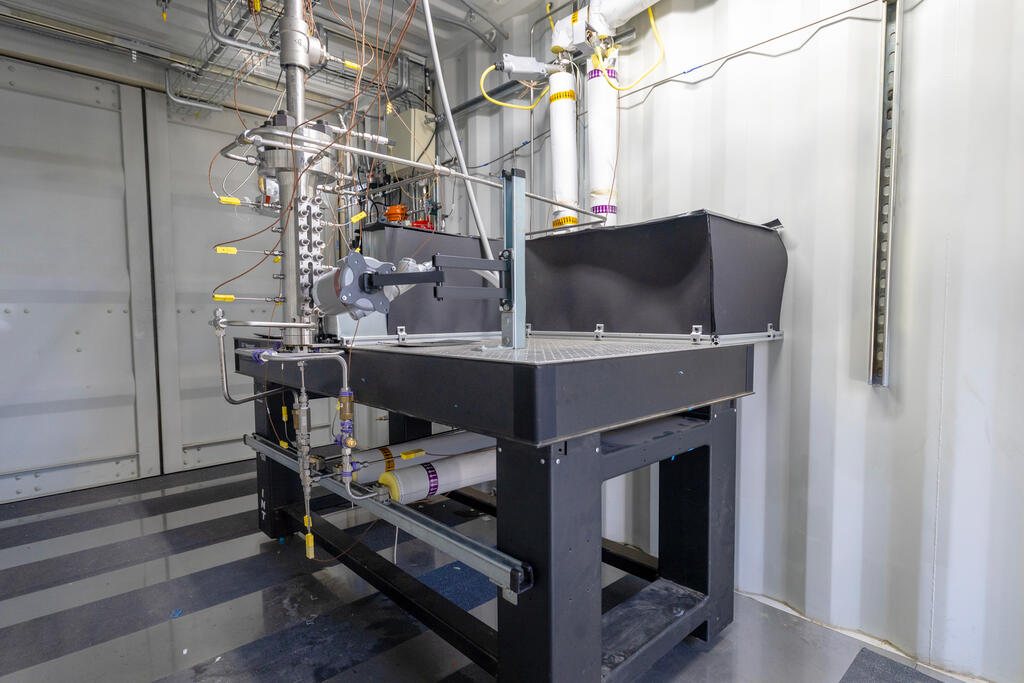

Micro Gas Turbine Test Facility – This facility investigates combustion in micro gas turbines with thermal power up to approximately 2 MW. Air is provided by a compressor able to deliver up to 2 lbm/s and 200 psig. A heater is installed in line with the compressor to heat up the air up to 500 degrees F to mimic desired compressor outlet conditions. A suite of pressure and temperature sensors is used to collect data from the test rig.

Oxy-fuel Combustion facilities – Our kW and MW thermal oxy-fuel combustion facilities investigate combustion in supercritical CO2 power cycles as well as other oxy-fuel combustion environments. The facilities have been designed to investigate combustion performance and emissions trough specifically selected sensors and optical access. Control systems have been designed to ensure precise composition of both fuel and oxydizer.

Unconventional Combustion System Research – We custom develop new test rigs and facilities to support client development efforts that span from cutting edge propulsion systems to industrial burners and combustors.

Expanded list of SwRI capabilities:

|

Computational Fluid |

Experimental |

Test Rig |

|

|

|

For more information, please contact Francesco Di Sabatino Ph.D., or call +1 210 522 2477, Chris Thomas , Ph.D., or call +1 210 522 3062, and Griffin Beck, or call +1 210 522 2509.