Corrosion sensors are an emerging technology that can improve data analysis of atmospheric corrosion impacts on materials and components. Atmospheric corrosion detection sensors are particularly suited to improve materials selection by providing sensitive and rapid measurements in a variety of environmental conditions.

The Corrosion Testing Laboratory at Southwest Research Institute (SwRI) develops and licenses corrosion detection sensor technologies for clients with unique challenges. We leverage our corrosion science expertise with knowledge of hardware and firmware designers to develop unique sensing systems. Additionally, SwRI has performed durability and longevity testing for sensor manufacturers and we served on the committee to develop NACE Standard TMO416, or “Test Method for Monitoring Atmospheric Corrosion Rate by Electrochemical Measurements.”

Corrosion Sensor Data Analysis

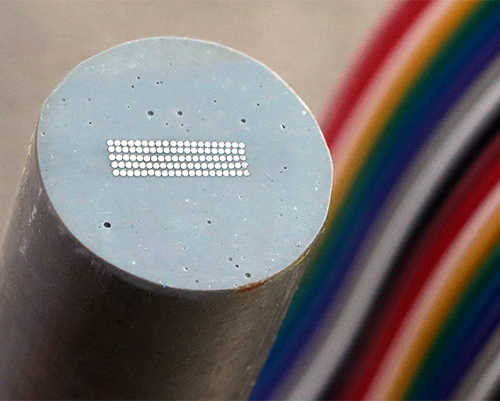

Corrosion detection sensors developed by SwRI

Inherent challenges of gathering and analyzing data from corrosion sensors has slowed adoption of corrosion detection sensors by a variety of industries. SwRI is helping change that with development of automated techniques and algorithms that enable clients to harness the power of corrosion sensor data to make informed decisions more efficiently. SwRI is leveraging advanced probabilistic data analysis techniques to predict corrosion rates. Initial laboratory testing and outdoor exposures have suggested these algorithms better predict observed corrosion than previous modeling methods.

Automated Data Analysis Tools

The SwRI-developed EStats software can classify environmental data by relative humidity condition, assisting in corrosion prediction and comparison of different exposure severities. Using environmental data such as temperature and humidity, SwRI is also leveraging advanced probabilistic data analysis techniques to predict corrosion rates. Initial laboratory testing and outdoor exposures have suggested these algorithms better predict observed corrosion than previous modeling methods.

Related Services

- Atmospheric Corrosion Research & Testing

- Corrosion Testing Laboratory

- Salt Spray Test Services

- Stress Corrosion Cracking

- Sulfide Stress Cracking (SSC) Testing

Or call James Dante at +1 210 522 5458.