About the Header

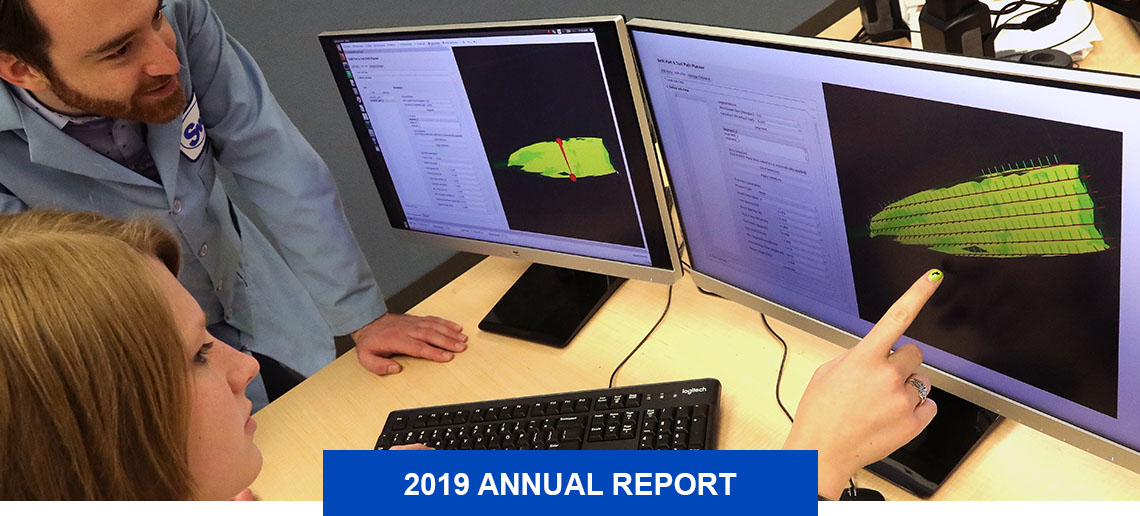

We used ROS-I software to automate paint stripping from a variety of aerospace parts using either chemical or media blast processes. SwRI’s unique solution automatically generates paths from CAD drawings or 3D scans.

Southwest Research Institute supports the manufacturing industry with advanced automation technology, creating adaptable tools while providing workforce training. We also help ensure that aging infrastructure and new construction products meet or exceed standards for safety, durability and performance.

Manufacturing

SwRI uses the ROS-Industrial open-source project to extend the capabilities of the Robot Operating System (ROS) to advance manufacturing. The ROS-I program and consortia have experienced strong growth over the past year, presenting new opportunities to use ROS-I capabilities in new manufacturing applications. For instance, we used ROS-I to generate world-class tool path planning capabilities that SwRI is applying in a wide range of industrial processes.

SwRI continued its long history of developing large robot depaint systems for the military and commercial aerospace industry. In 2019, we completed construction of the world’s largest mobile manipulator that precisely strips coatings from aircraft using a laser.

To validate a client’s computational models with real-world experimental data, SwRI exposed a bare structural I-beam to a 1.8 MW fire scenario. Scientists successfully recorded temperature and displacement data as the beam buckled under the extreme conditions.

SwRI built and demonstrated the world’s largest mobile robot system. This first-of-its-kind automated system uses a laser to remove coatings from large aircraft.

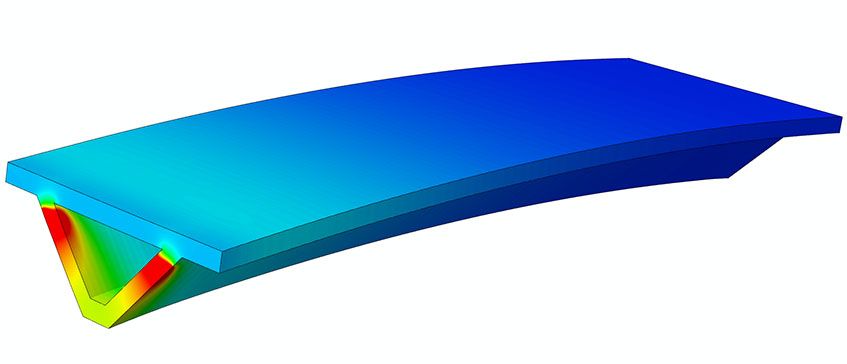

Additive manufacturing (AM) uses 3D printing technology to fuse metal powders layer-by-layer to build complex components. Predicting the material properties, strength and durability of these components is complicated. The additive buildup of material could produce potentially severe residual stresses that distort components, introduce heterogeneous microstructures and alter material properties as compared to conventionally wrought materials. As part of an internal research program, SwRI is building a computational model of the selective laser melting AM process to rapidly qualify new components. This model uses thermal histories to drive computational predictions of residual stress and average grain size in the material microstructure.

SwRI operates a Texas Manufacturing Assistance Center, helping small and medium manufacturers in Central Texas compete in the global economy. We have expanded staff resources in Austin to address the area’s considerable manufacturing market.

CONSTRUCTION

In the U.S. and abroad, pipelines, offshore platforms, railway bridges, dams and power plants are nearing, or have surpassed, their original design life. Because this infrastructure is considered too costly to replace, SwRI offers a portfolio of fitness-for-service evaluations and potential life extension solutions for these aging systems. Our engineers offer a multidisciplinary approach to assessing these structures with nondestructive evaluation techniques to inspect, monitor and analyze data under real-life operating conditions. SwRI performs fatigue life assessments using classical methods and tools such as ANSYS® and NASGRO® fracture mechanics and fatigue growth analyses, all with the goal of cost-effectively addressing the challenges of aging infrastructure.

Through an internal research program, SwRI engineers are developing techniques to predict the thermal profile of a redesigned aerospace component using additive manufacturing computer simulations. High temperatures near the build surface reflect localized heating from the laser heat source.

Another challenge with aging systems is difficulty finding replacement parts and technology. Aging equipment often requires components to be deconstructed to produce a functional replacement. In 2019, SwRI performed a functional analysis and reverse engineered a telecommunications data transmission system. Engineers disassembled two of the units, producing a complete electrical diagram of the system, including connections and components.

To ensure the safety of manufactured building and transportation components, we operate one of the world’s largest organizations dedicated to fire technology, research and testing. In 2019, we studied how utility poles stand up to high-intensity, relatively short-duration wildfire flame fronts. To evaluate fire performance, we conducted a series of tests on 22 types of utility poles. We subjected them to up to three minutes of high-intensity fire exposure, measuring pole and flame temperatures, fire exposure heat fluxes and pole deflection.

For more information visit Manufacturing & Construction.