Many industrial processes, such as sanding or mechanical assembly, require a force applied and/or monitored to execute the process. This can be accomplished either through built-in compliance in the interaction between the tool on the robot and the part being worked on or through a rigid interaction and a controlled force being applied by the robot itself. Historically, Southwest Research Institute has used the former option in most applications. With the rise of collaborative robots, and the ease of access of force feedback information, the latter of these two options is now technically achievable without expensive and cumbersome end effectors.

Software Controls Force and Speed

Through a recent targeted internal research project, SwRI developers leveraged existing open-source software to develop a hardware-agnostic, through-arm force control, software solution. While specific closed-loop force control systems already exist, this software allows for a more general approach that can easily fit into future robotics applications. If a robot supports trajectory streaming capabilities and there is a force sensor on the end effector, whether it is built in or third-party, this system allows for simultaneous force and speed control.

Universal Robots Force Control Project

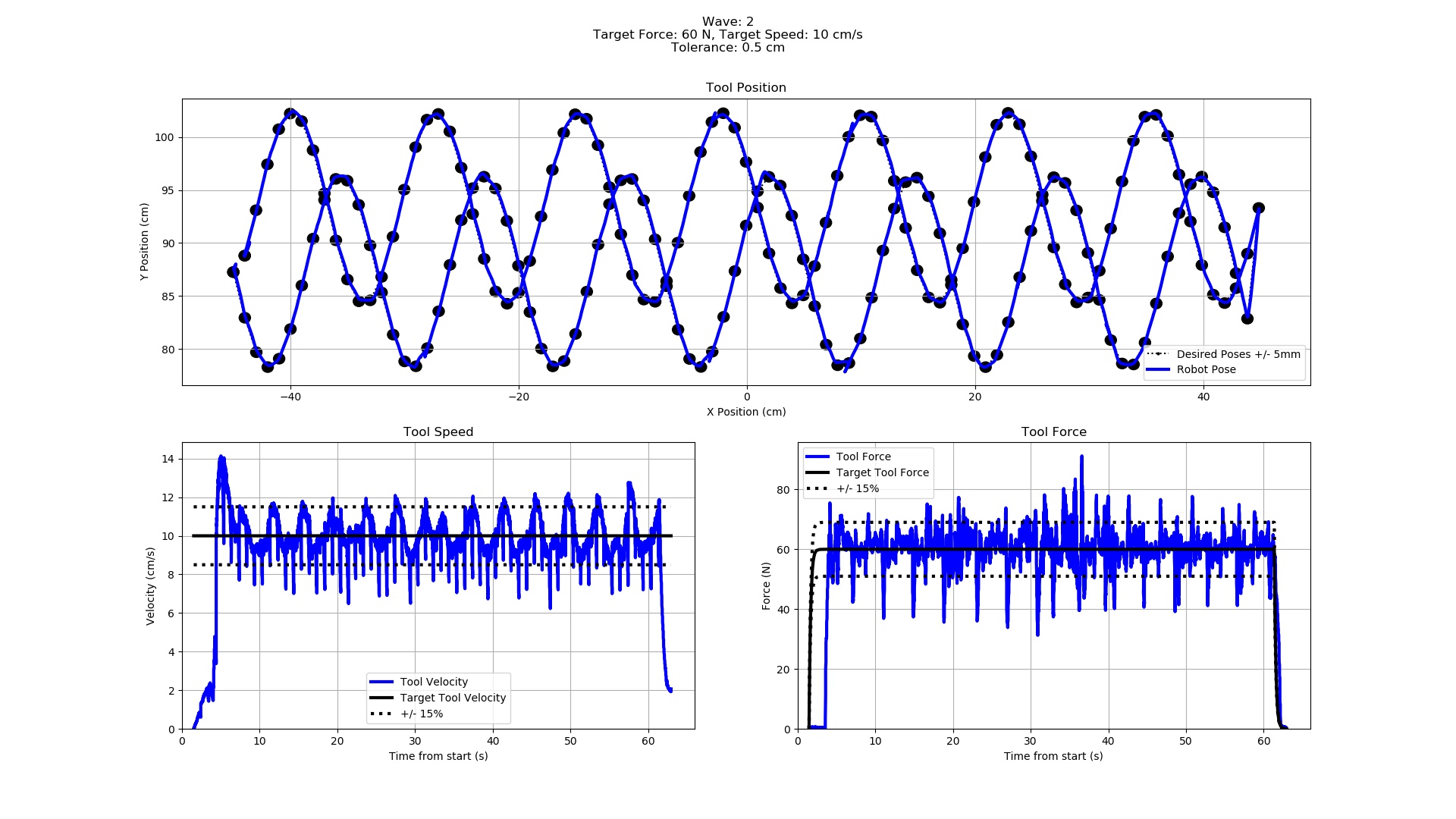

This new software was tested on a UR10e collaborative robot in various situations. The robotic arm was instructed to follow a sine wave across a flat surface with a target force of 60N and speed of 10cm/s. The results graphs, while somewhat noisy, demonstrate a high accuracy of position, speed, and applied force. In the following video you can see the robot simulating a sanding process by moving across a curved surface. Prior to beginning the movement, the robot was required to identify the target location; this demonstrates the feasibility of using this approach in scan-and-plan applications.

Some possible future applications of this could include material removal, coating removal, buffing, polishing, and any process that may require constant force and velocity.

This work will soon be available and open-source on the SwRI Robotics GitHub page. Visit the ROS-Industrial Blog to read about an aerospace project that uses this force control technology.