Universities, startups, and R&D organizations are facilitating the rapid evolution of industrial automation and robotics with innovative prototypes and emerging technologies. These new and exciting capabilities are gaining footing in manufacturing and industry, but a gap has emerged in system sustainability, not to mention broader adoption across the industrial domain: workforce development.

The ROS-Industrial project has enabled many of these innovations. Southwest Research Institute (SwRI) initiated ROS-Industrial to bring the benefits of the Robot Operating System (ROS) and other open-source platforms to industrial applications. Over more than a decade, ROS-Industrial has evolved into several research consortia with exciting deployments worldwide.

Through ROS-Industrial, we have learned that sustaining a novel robotics capability can be challenging if an organization lacks the strategy or skills to update software and hardware, or even adapt to changing priorities.

Developing advanced capabilities with open-source tools such as ROS often leads to a custom software solution, usually in the Linux operating system. Debug and maintenance, beyond the basic operator graphical user interface, usually involves command line work in a Linux terminal. The typical manufacturing engineer or robot technician is not trained for these requirements, which can lead to costly support calls and follow-up development.

To address these challenges, SwRI and ROS-Industrial are developing training that facilitates and builds in sustainability.

Training & Recruitment Sustain Innovation

A recent project, sponsored by the membership-based consortium known as the ARM Institute, presented SwRI with an opportunity to initiate workforce development for ROS-based systems. The project, titled “Collaborative Robotic Sanding of Aircraft Panels,” was coordinated by Spirt AeroSystems and supported by SwRI and Wichita State University with the goal to develop a Collaborative Robot Sanding tool.

From the start, it became evident the team needed a long-term strategy to sustain advanced system development in manufacturing ecosystems with a viable talent pipeline. Significant “rethinking” of the training paradigms took place during the development program.

Rethinking training and education for programs that leverage the ROS-Industrial framework for manufacturing.

As part of the Collaborative Robotic Sanding project, a ROS-Industrial training event was conducted. Not only would this enable attendees to become familiar with ROS and support contributions in the software task flow of the project, but also enable an understanding of the technical needs related to ROS-based systems. Upon completion of the ROS-I training event, held over three days in June 2019 at the National Institute for Aviation Research (NIAR), a survey captured the following takeaways:

- Pre-work for C++ would help

- Copy and Paste without the “why”

- More explanation of what is going on

- A lot for two days, maybe more detail and foundation to cover in two days

- The ability to do more, and make changes via Python

- More of an intro and the functional intent and best practices for CMake

- How do we know who is connected? How do you properly network systems?

- Securing of network – best practices wiki, but not in training (yet)

- At end of training, those coming in with little, to no training, did not feel confident they could troubleshoot a ROS-based system

The current curriculum is slanted toward people with proficiency in Linux, Git tools, and C++. However, in most engineering programs, outside of computer science, C++ instruction is limited, if not nonexistent. Most manufacturing engineering students may only receive cursory introductions to Python or other scripting languages. This provides the initial hurdle, and it manifested itself in the feedback from the training.

The other glaring challenge is the amount of content for the two days of instruction. This is often the case even for students with a decent understanding of C++. However, within the group that provided feedback for this project, there was little to no prior experience with C++, further highlighting the challenge for this audience.

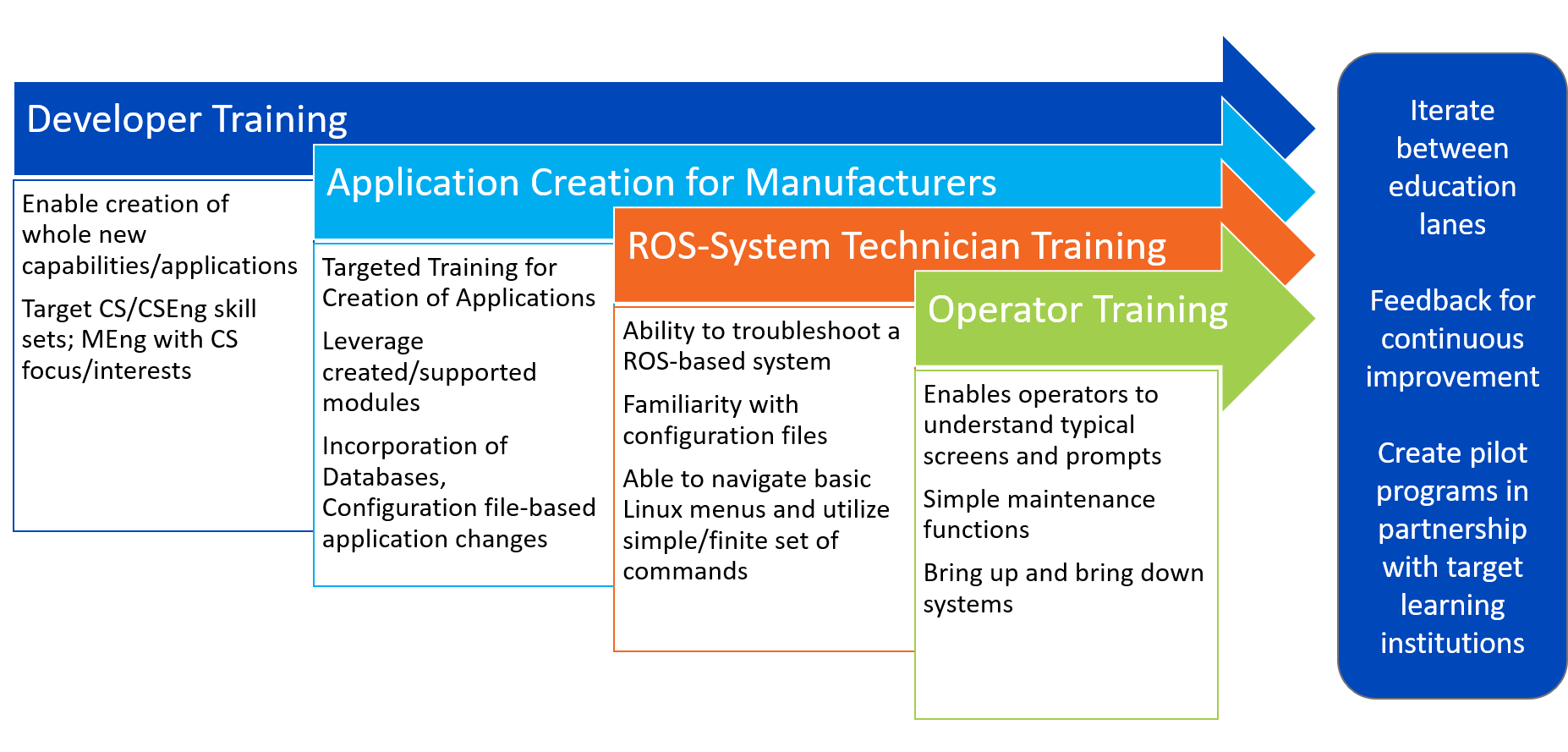

While having training for developers and engineers with C++ experience who need to develop applications using industrial hardware is still a need, the feedback highlights that additional training categories are required. Additional subsets of training may be created to build off each other in a university-style framework.

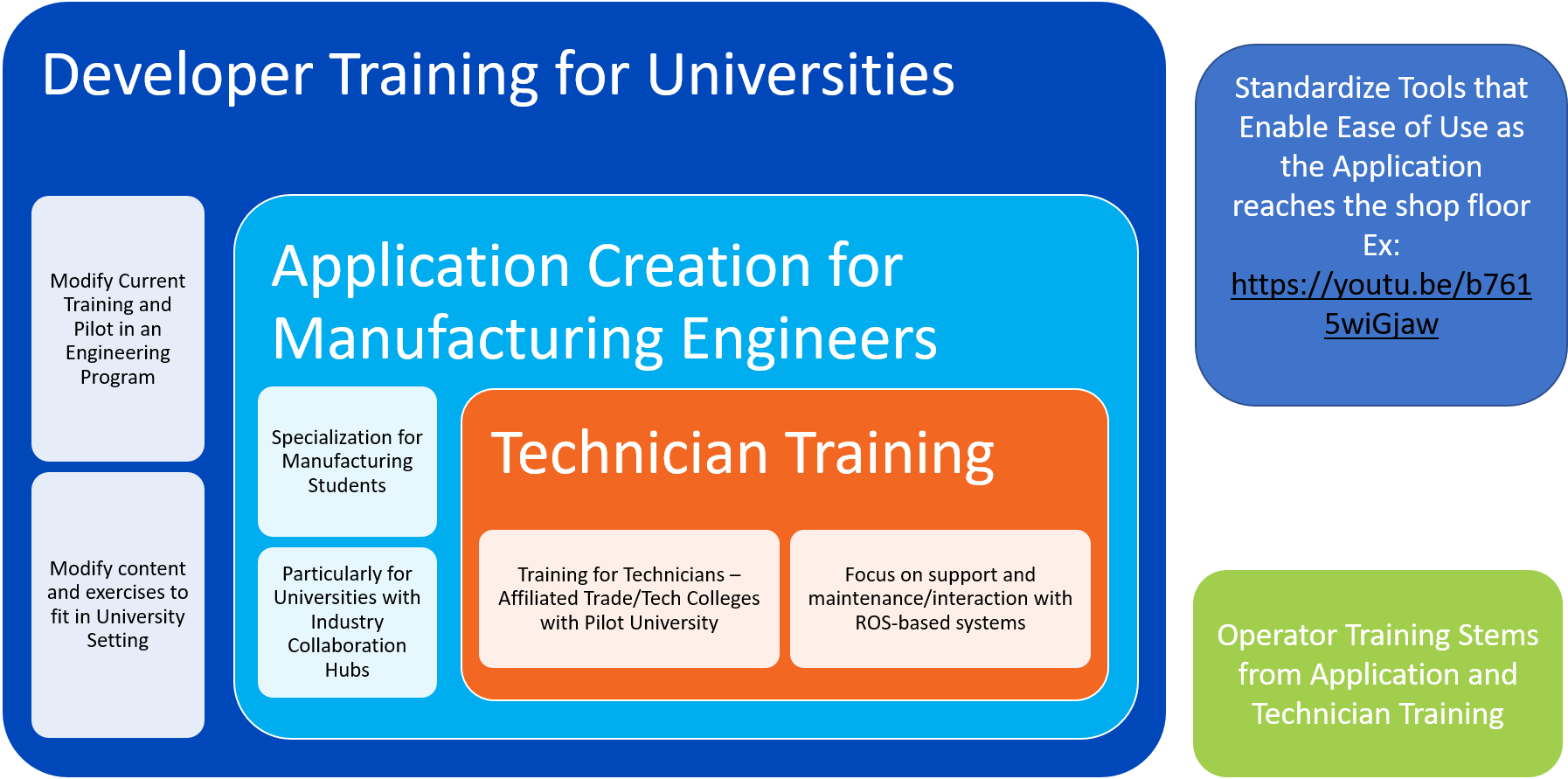

Concept for developer training for universities.

A Path to Manufacturing Technologies Education

In this scenario, we can create and build from the current training, adding content over the course of a semester. Once the core curriculum is established, a subset of classes may be created that form a specialization for manufacturing engineers. This would include application set up, leverage of configuration files and troubleshooting utilities to modify existing systems, and add blocks of functionality, compared to application development from scratch. From there, a manufacturing technologies educational program could develop supporting curriculum that focuses on troubleshooting, system configuration, and efficient means of taking systems on and offline, etc.

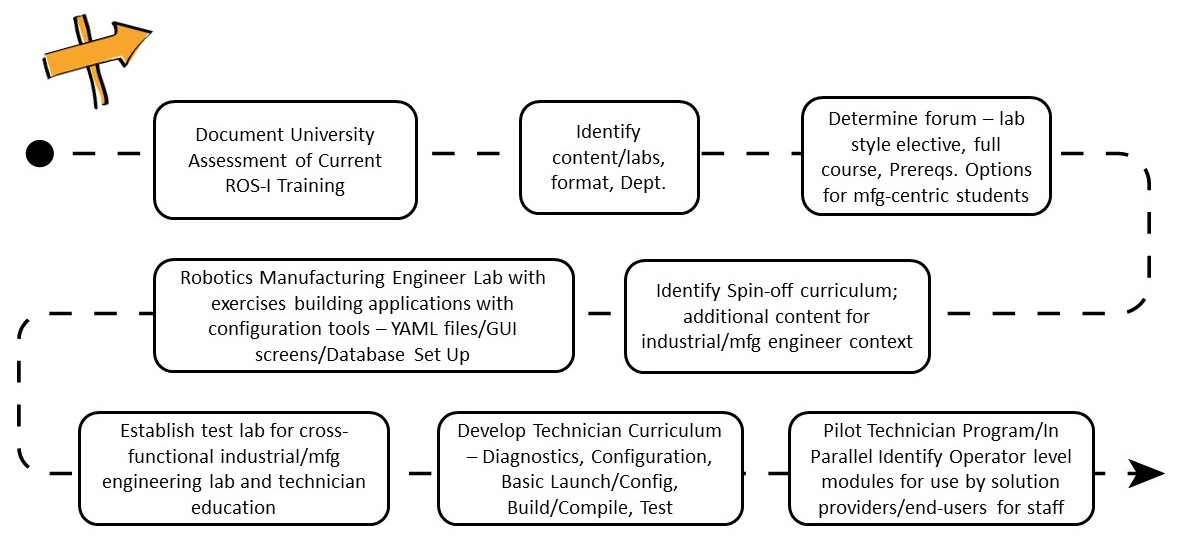

At a high level, over the course of 2-3 semesters, a rollout to build this nested advanced robotics educational framework could follow a structured path adding additional learning opportunities as the program matures.

Path for planning advanced robotics education.

Here, available resources would be leveraged as much as possible, and modified/scaled to meet the needs of the engineering program. From there, the relevant components would be identified and modified to fit into the next phase: manufacturing engineering robotics specialization. As these modules become refined, improvements may be pushed back to an open-source platform to enable other educational institutions to leverage and drive scale at optimized cost, building an educational ecosystem to drive the talent pipeline that will support the advanced robotics systems of tomorrow.

Next Step: Working with Academia & Industry

As an output of the Collaborative Robot Sanding project – which involved team members in academia, industry, and nonprofit research – this model may be put to the test. Under current development is a tech program that seeks to introduce the technician student to ROS-based systems and provide resources around understanding their inner workings. While this program is currently in the initial planning phases, we look forward to supporting and working with the university partner and others to build out the educational pipeline for the workforce for tomorrow.

Tell us more about the challenges you face with sustaining training and workforce development for your industrial robotics and automation initiatives.