About the Header

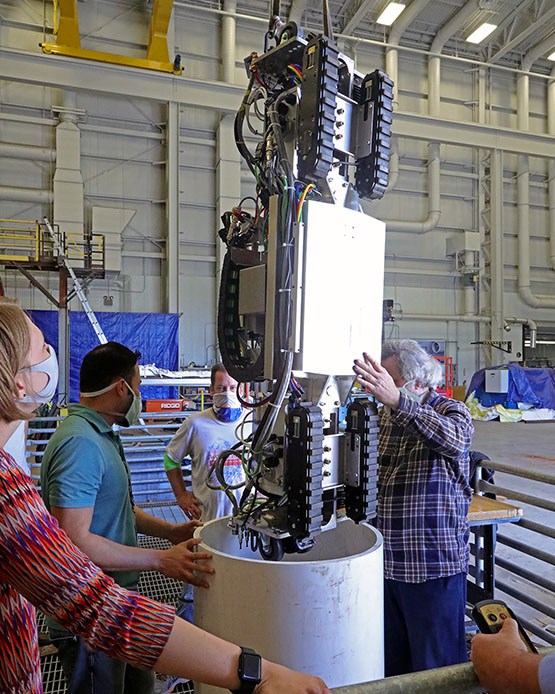

This complex custom test stand evaluates the structural integrity of Next Generation Jammer pods under real-world conditions. The pods are installed on EA-18G Growler aircraft to thwart enemy radar and targeting systems.

Southwest Research Institute supports the manufacturing industry with advanced automation technology, creating adaptable tools while providing workforce training. We also help ensure that aging infrastructure and new construction products meet or exceed standards for safety, durability and performance.

MANUFACTURING

In the field of manufacturing automation, SwRI has pioneered using the Robot Operating System (ROS) to advance manufacturing with the ROS-Industrial (ROS-I) open-source project. For the past seven years, we’ve led the ROS-I Consortium through global collaborations in Europe and the Asia Pacific region. In 2020, we developed several projects with ROS2, the newest version of ROS. We have also applied ROS-I in a wide range of industrial processes, including automotive and aerospace applications, automating path planning to paint or sand a wide range of components.

In 2020, SwRI celebrated 25 years of operating the South Central regional office of the Texas Manufacturing Assistance Center (TMAC), serving 159 manufacturing companies in the area this year.

RELIABILITY

In the U.S. and abroad, manufacturing and construction projects ranging from bridges to pipelines to aircraft are nearing, or have surpassed, their original design lives. Because this infrastructure is considered too costly to replace, SwRI offers a portfolio of test technology, fitness-for-service and potential life extension solutions for these aging systems. Over the past 40 years, SwRI has become internationally recognized as one of the world’s leading independent aerospace structural integrity and testing laboratories supporting commercial and government clients. We conduct component and full-scale structural static, fatigue, vibration and impact tests, including bird strike simulations. We use computer-aided design and finite element analysis tools to design complex test fixtures, ensuring accurate test loads and enforcing proper boundary conditions.

Our Aircraft Structural Integrity Program (ASIP) conducts aircraft usage monitoring, structural analysis, testing and nondestructive inspections. Integrating this ASIP information allows the Air Force to manage the risks of operating its aging aircraft fleet. New aircraft data recorders track A-10 usage, while laboratory testing determines basic material properties and damage tolerances. We conduct component and full-scale testing and analysis and use our patented magnetostrictive sensors to assess the structural health of the A-10.

SwRI automation and nondestructive evaluation engineers demonstrate how a custom mobile robot navigates a tight spot to ultimately evaluate the integrity of double-wall storage tanks that hold chemical and nuclear waste.

SwRI engineers are developing a fully automated tractor system for vineyard operations management. Multi-sensor data fusion perception systems interface with the autonomy kit to support path planning and navigation.

Recent improvements to the CH-47 helicopter include the addition of an advanced actuator. SwRI is updating, validating and verifying depot maintenance work requirements for the device, including functional and environmental stress screening (ESS), which exposes manufacturing defects using thermal and vibration stresses during operation. SwRI is modifying the rotary electric test stands to accommodate functional testing of the new actuator, designing and building instrumentation to monitor the device during ESS testing, and performing the temperature and vibration tests required.

For military aircraft engines, SwRI is developing a flight line system to test T5 amplifier system components for the J85 turbo-jet engine that powers the T-38 and F-5 aircraft. The tester will evaluate the T5 under both static and dynamic engine states. Currently these components require removal for testing. SwRI is designing and prototyping a portable test system to isolate faults on-engine so the unit is only removed and replaced when necessary.

SwRI continues to upgrade the Engine Tracking Database System (ETDS), which helps friendly foreign militaries around the world support and maintain the F110 engines used in F-15 and F-16 aircraft. The ETDS program facilitates tracking and management of parts, maintenance, usage and inspection data for the F110 family of engines. Seven allies currently use the system, with additional countries coming online soon.

SwRI continues to improve the DARWIN® probabilistic fracture mechanics tool used to design and certify aircraft engines, most recently to address a nickel disk fracture that caused an engine to catch fire.

In addition, SwRI engineers are developing and using our NASGRO® and NESSUS® software to evaluate the fitness-for-service of NASA’s aging ground-based pressure vessels. Since 2014, SwRI has enhanced the NASGRO fracture mechanics and fatigue crack growth software to enable NASA to manage its aging layered pressure vessels.

For more information visit Manufacturing & Construction(link is external).