Foams offer a novel way to reduce water usage, or tune the density of a fluid, for industrial use. These two-phase fluids offer a solution to many issues faced in the oil and gas industry. SwRI’s Foam Research Facility is a pilot-scale flow system where petroleum and aqueous based foams can be studied at elevated temperature and pressure conditions encountered within the well bore or reservoir.

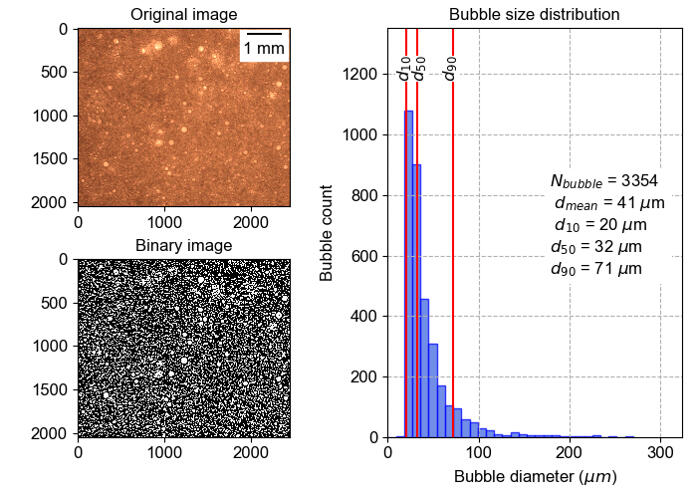

Foam texture is a crucial measurement to understand foam stability over time. A custom bubble analysis algorithm created by SwRI measures the bubble size distribution of trapped foam samples to quantify foam texture.

The Foam Research Facility combines base liquid with a gas-phase at elevated pressure in a single-pass foam generation system. The facility’s foam generation system is configurable to allow customers to optimize their foam for maximum stability and the desired texture. Foams can be studied in a variety of single-pass and recirculating test fixtures downstream of the foam generation system to better understand their performance in realistic operating scenarios. A specialized thin film sight glass is outfitted with a microscope to take still images of the foam, and a custom algorithm can be employed to quantify the foam texture through bubble size distribution analysis.

Foam structure stability can be measured on a microscopic scale through the sight glass, or on a more macro scale with two custom test sections. Each test section has an overall length of 10 to 18 feet and are inclinable up to 30º from vertical. The inner geometry of these pressurized fluid columns mimics typical oil and gas downhole conditions, such as a drilling application or production tubing.

If foam research is required, SwRI is able to replicate specific chemical compositions, foam generation techniques, and downhole conditions. The Foam Research Facility’s capabilities include:

- Compatibility with nitrogen (N2) or methane (CH4) foams with aqueous or petroleum base fluids

- Foam generation at up to 2.5 gpm

- 0-100% quality foams at 7,500 psi and 350ºF

- Foam texture, foam half-life, rheology, pressure transmissibility, heat transfer, and foam stability measurements

- Simulated wellbore test fixture for drilling or production analysis at field conditions, with optional fluid recirculation capabilities

- Gas kick and gas migration testing

Learn about SwRI’s ongoing research of natural gas foam as a hydraulic fracturing fluid here.

Contact Griffin Beck at +1 210 522 2509 or Angel Wileman at +1 210 522 2657 for further inquiries.