About the Header

In 2021, we completed a multiyear program to upgrade our fuels and lubricants storage capabilities. The new facilities support clients’ access to the lubricants they have stored using SwRI’s client portal, developed last year.

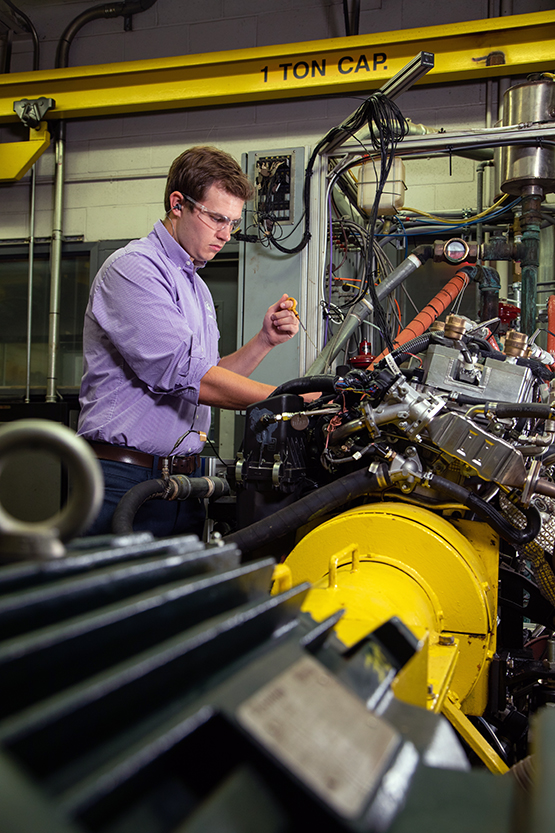

For nearly 75 years, Southwest Research Institute has been involved in nearly every facet of automotive and transportation research, from powertrains to fuels and lubricants to intelligent highways and connected and automated vehicles. In 2021, we saw one of the most significant industry pivots in a century, as the automotive industry embraced an unprecedented shift to electrified powertrain research and development. In response, SwRI launched new research initiatives to address greenhouse gas emissions and improve vehicle efficiency, including new efforts in electrification and connected vehicle systems.

AUTOMOTIVE

Since SwRI’s founding, our engineers and scientists have evaluated functional fluids used in transportation applications to ensure they meet certification standards. SwRI has worked with engine manufacturers for decades to develop test standards and protocols that ensure fluids on the market will protect various engine designs. As the industry transitions to electrified powertrains, SwRI is working on two internal research projects studying how fluids age in electric powertrains and looking at performance properties from oil fill until oil change. Understanding how fluids age and the properties of aged fluids could support the future development of a controlled aging method. In addition to studying lubricant aging, we will assess vehicle efficiency changes associated with aging fluids. These projects use two types of electrified vehicles; a pure electric vehicle (EV) and a plug-in hybrid that has a conventional hybrid powertrain in the front and an electric rear axle. The projects will support standardized test development for EV fluids.

In 2021, we adapted laboratory equipment to support the continuing shift to electric and hybrid-electric platforms. New chassis dynamometers provide loads of up to 300 horsepower independently to a vehicle’s front and rear axles.

SwRI also launched the Advanced Fluids for Electrified Vehicles (AFEV) Consortium in 2021 to enhance the industry’s understanding of the unique stressors placed on electric vehicle and hybrid vehicle fluids. Because many automakers currently use conventional fluids in electrified powertrains, the new research will support the development and optimization of EV fluids and advance EV powertrain design.

On the battery side of EVs, engineers are using internal research funds to tackle challenges with recharging batteries. While consumers need only a few minutes to fill a tank with fuel before they can get back on the road, an EV typically needs hours to do the same. Fast recharging maximizes the transfer of lithium ions within a battery pack. However, at high rates, ions can accumulate on the surface of the battery’s anode and deposit metallic lithium through a process called “lithium plating.” This phenomenon can reduce battery performance and service life and, if left unchecked, can cause it to short circuit and fail. The electrochemistry that causes lithium plating is complex and not completely understood. SwRI is developing a physics-based model that allows us to detect, in real time, the occurrence of lithium plating so we can continuously adjust the charging rate to prevent battery damage while also allowing for shorter charging times.

SwRI monitored various electric/hybrid cargo-handling systems including this hybrid crane, as well as their conventional diesel-powered counterparts, to help a client optimize electrification plans for lower-emissions operations.

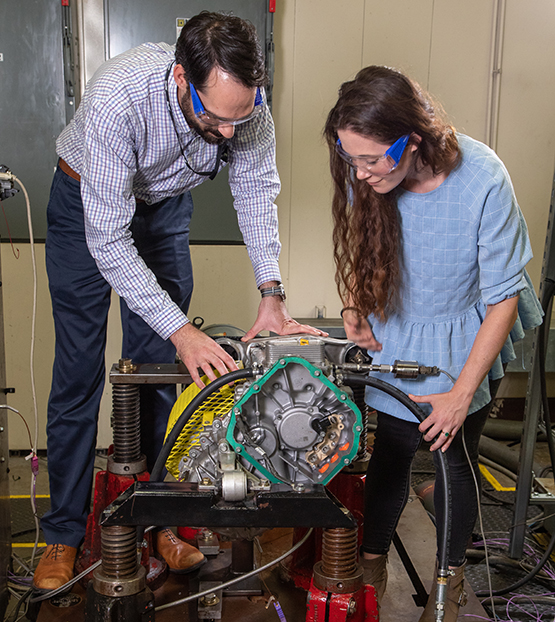

SwRI recently developed a valvetrain wear test to address concerns that products on the market were causing wear issues in a popular pickup truck engine.

Working with a commercial client and the California Air Resources Board (CARB), SwRI analyzed electrified cargo-handling equipment as part of a CARB zero and near-zero emissions freight facilities initiative. SwRI used dataloggers to monitor a battery-electric locomotive, a hybrid crane, an electric side pick cargo handler and an electric Class 8 drayage truck, as well as their conventional diesel-powered counterparts. Data collected included energy consumption, refueling and recharging times and peak electricity rates in addition to emissions for the diesel-powered equipment. At the project’s peak, 10 data-loggers monitored the energy consumption of all vehicles in operation. SwRI’s analytics team then distilled the data into objective metrics to help the client optimize its electrification plans for cargo handling equipment in California.

In the conventional fluids arena, a new API heavy-duty engine oil specification known as PC-12 is on the horizon for the trucking industry. Both CARB and EPA are moving toward tighter emissions limits and longer equipment life requirements. By 2027, the lubricants used in on-highway trucks must meet new challenges, including lower viscosity specifications and longer drain intervals, while still minimizing component wear.

In 2021, SwRI developed a valvetrain wear test to address concerns that products on the market were causing wear issues with a unique engine used in one of the most popular pickup trucks in America. Engineers developed this test as a tool to demonstrate the ideal lubricant performance needed to keep these trucks on the road. As the test moves into the PC-12 oil category, it will help ensure broader protection for diesel production engines.

SwRI launched the Advanced Fluids for Electrified Vehicles Consortium in 2021 to improve the industry’s understanding of the unique stressors placed on electric vehicle (EV) and hybrid vehicle fluids and how that affects components.

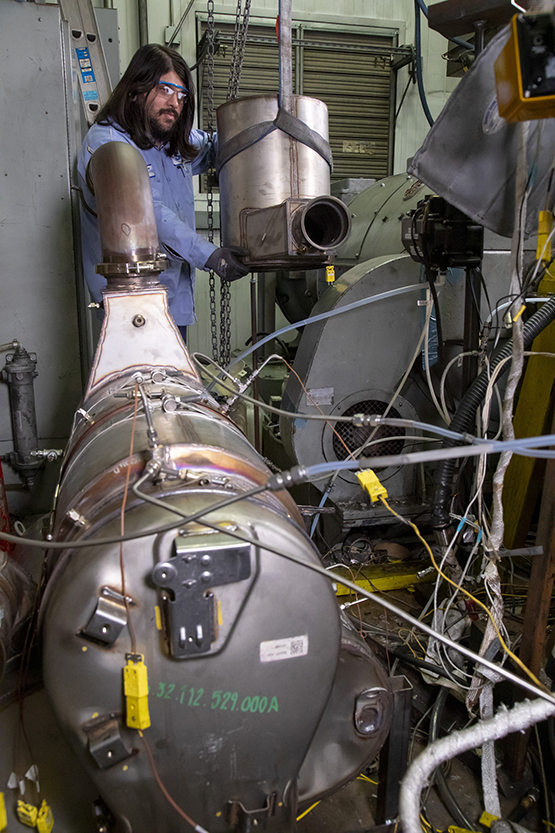

Through a multiyear DOE program, SwRI is investigating “cooled spray” technologies to control particulate emissions from nonroad heavy-duty diesel engines.

SwRI also offers a unique, 3,000-square-foot tribology lab focused on friction, wear and lubrication, particularly in automotive applications. In 2021, they continued to develop new testing techniques and tribometer modifications to meet a range of client challenges.

In a multiyear DOE Vehicle Technology Office program, SwRI is investigating “cooled spray” (CS) technologies for controlling particulate emissions from nonroad heavy-duty diesel engines. Cooled spray technology uses a monolithic insert with multiple fuel and air passages installed in the cylinder head that mounts over the fuel injector nozzle. The CS program aims to achieve a 75% reduction in particle emissions over the full operating range, while developing scaling rules for small and large engines. Engineers will conduct evaluations in a high-speed single-cylinder engine at SwRI’s Large Engine Facility.

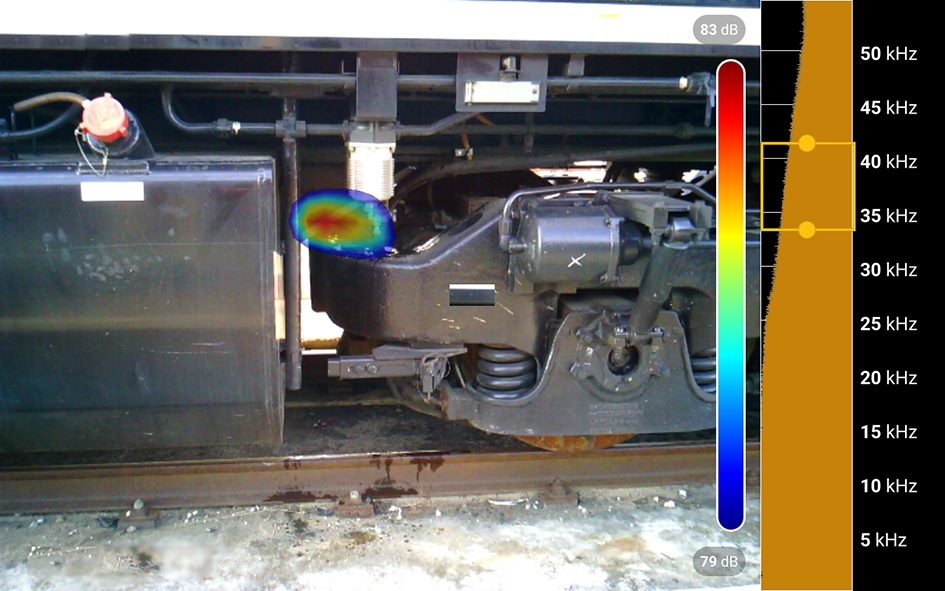

Combining commercial AI systems with our machine vision expertise and an optimized microphone array, SwRI developed a system to automatically detect wasteful air leaks on moving trains, providing maintenance teams with a photo and location of the leaky equipment.

In 2021, SwRI assembled an international team to develop a system to autonomously detect compressed air leaks on moving freight and passenger trains. Trains require compressed air for brakes, horns and various other functions. Any air leaks are difficult to find and require the locomotives to pump more air to keep the train running safely. Reducing these leaks will result in significant operational, safety, fuel consumption and environmental benefits. The project goal is to combine SwRI’s locomotive performance and machine vision expertise with a commercially available audio sensor to create a wayside detection system. The resulting system will automatically detect air leaks on moving trains, notifying maintenance teams with detailed information about the location of the suspected leak, including the specific car and its location within the train as well as a photo of the leak location.

Through a new DOE contract, SwRI will continue developing its cutting-edge connected and automated vehicle (CAV) technologies to help passenger vehicles operate more efficiently while reducing energy consumption and carbon emissions. The award-winning Advanced Research Projects Agency-Energy (ARPA-E) Next-Generation Energy Technologies for Connected and Autonomous On-Road Vehicles (NEXTCAR) program demonstrated over 20% improvements in energy consumption in real-world driving conditions through a combination of vehicle dynamics and advanced powertrain control algorithms including eco-routing, eco-driving and power-split optimization. In the second phase, SwRI will build on those technologies and expand its predictive eco-driving feature. This algorithm helps human drivers make smarter decisions based on localized traffic through vehicle-to-everything connectivity and communications. Because of the improved perception and actuation precision of a Level 4 autonomous vehicle over a human driver, SwRI will expand the eco-driving framework to optimize for automation and multilane dynamics to further reduce energy consumption.

SwRI’s multiyear low-NOx engine development program has progressed from regulatory support to new aftertreatment systems and software and hardware support. NOx is a generic term for the nitrogen oxide emissions associated with air pollution.

As hybrid vehicles proliferate, SwRI is addressing concerns about oil emulsions forming in association with short drive cycles in cold weather, developing engine tests to replicate these phenomena and evaluate whether different formulations could mitigate the effects.

For more than 60 years, SwRI has hosted a government-owned, contractor-operated facility to provide advanced vehicle fluids research, development and engineering for the U.S. Army and other government agencies. In 2021, we renewed our multiyear contract to operate the U.S. Army Ground Vehicle Systems Center Fuels and Lubricants Research Facility on our grounds.

Chemical engineers collaborated with automotive specialists to help a client develop a post-refinery process to reduce exhaust emissions from diesel engines by overcoming the soot/nitrogen oxides (NOx) reduction trade-off that has plagued engine researchers for decades. The result is a modified fuel that potentially could replace today’s ultra-low sulfur diesel, biodiesel and other renewable diesel fuels.

Using internal funding, chemical engineers developed the “EZ Flow™” process to treat heavy crude oils, making pipeline transportation of the commodity more cost-effective and less energy-intensive than current techniques. The new processing method uses a proprietary chemical treatment and mechanical technique to reduce the viscosity of heavy crude oil by more than 60%, allowing it to flow more easily through existing pipeline networks.

In Florida, SwRI was awarded and is developing a statewide data exchange capable of ingesting high-volume, high-velocity data from diverse transit sources, particularly connected and automated vehicles.

TRANSPORTATION

In 2021, SwRI expanded its intelligent transportation partner network to 14 states and one U.S. territory. We deployed our ActiveITS™ Advanced Traffic Management System (ATMS) in Kansas using cloud technology and began a pilot program in Albany, New York. We are also helping Pennsylvania maintain its existing ATMS while developing and integrating new capabilities.

In Florida, SwRI launched a state-wide data exchange capable of ingesting high-volume, high-velocity data from diverse transit sources, particularly connected and automated vehicles. Once complete, the platform will facilitate real-time detection/notification of actionable conditions while archiving data for advanced analytics and machine learning applications in the future. This data exchange platform, ActiveDX, can be licensed to other public agencies.

SwRI is using machine learning and connected vehicle technology to expedite public transportation using an exclusive bus lane in the Lincoln Tunnel to improve flow between New Jersey and Manhattan. The goal is to increase bus trips using a narrow lane that reverses direction to accommodate morning and evening commuter traffic.

SwRI develops automotive cyber-security solutions to protect proliferating embedded electronics and networks in newer vehicles. SwRI evaluated multiple ethernet intrusion detection systems for a leading automobile company. In addition, we analyzed EV charging protocols to identify potential security risks through internal research funding.