Background

Robust electric vehicle (EV) charging infrastructure is essential to promote wide-scale adoption of EVs by alleviating concerns such as range anxiety and long charging times. While almost a quarter of all charging stations in the US support high-power direct current (DC) charging, customers still experience long charge times at these locations. Various stakeholders have expressed interest in understanding these limiting factors, which are currently not evident in commercially available charging stations. Additionally, charging the ever-increasing number of EVs poses several challenges to the electric grid. Vehicle-to-grid (V2G) technology offers a promising solution by enabling EVs to not only consume electricity but also feed excess power back into the grid, transforming the EVs into mobile energy storage units. Currently, there are limited commercially available off-the-shelf solutions that provide an economically feasible high-power charge and discharge (bi-directional DC power transfer) solution incorporating internal vehicle data.

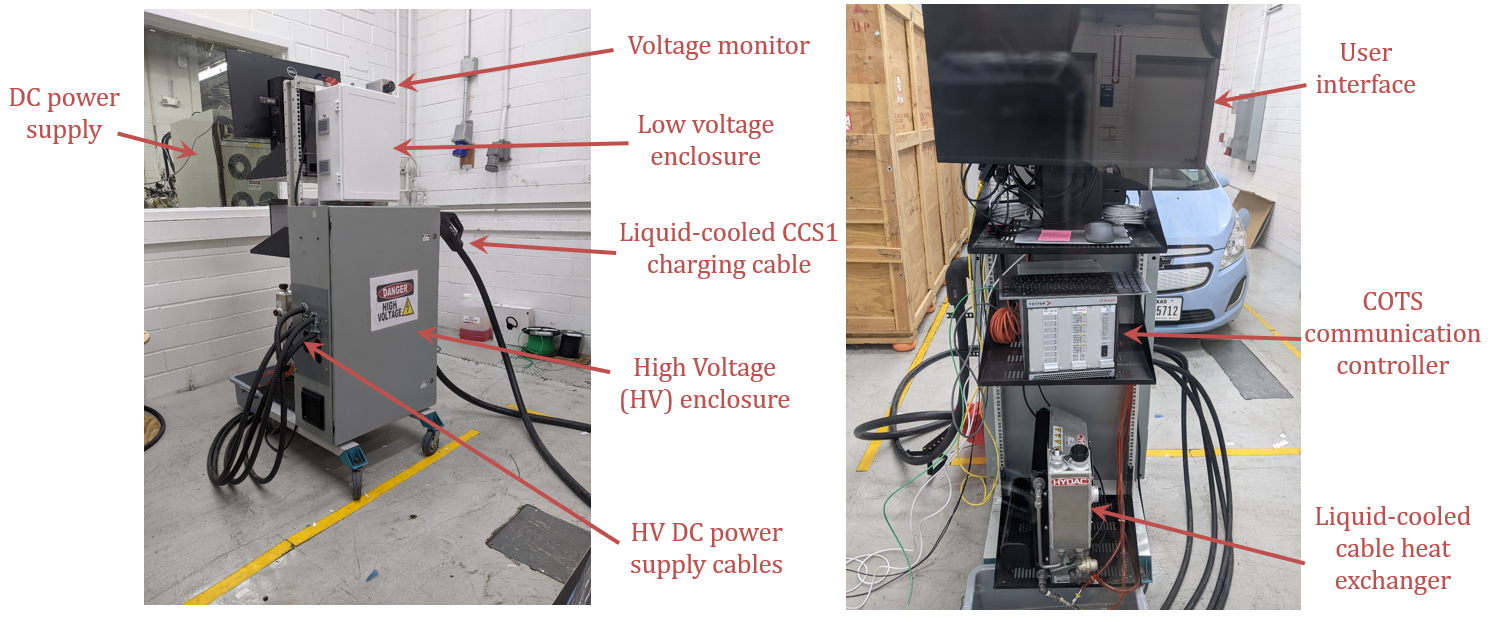

Figure 1: The DC power transfer setup with various components shown.

Approach

The aim was to design a high-power (>150 kW), DC power transfer setup and demonstrate DC charging in a research setting that allows access to low-level information exchange containing key parameters linked to energy exchange and independent measurement of electrical energy. The objective included creating a scalable, modular, and portable setup to facilitate future upgrades and maintain accessibility throughout the institute.

Accomplishments

A scalable, modular, portable DC power transfer setup sized to 400 kW was built. The setup was used to successfully charge two EVs with different charging interfaces – a Tesla Model 3 and a Hyundai IONIQ5. Charge rates of over 150 kW were observed, with the rate limited by the EV in both cases. This made the setup the fastest DC EV charging solution on the main SwRI campus. This project served as a starting point allowing us to further build capabilities with DC discharge, which has implications for grid applications and the current SAE J1634 testing procedures both of interest to EV manufacturers and regulators. The setup would also allow for conducting EV battery diagnostic, and prognostic tests, which is a topic of interest to EVESE-II consortium members, and eventually help EV manufacturers prolong battery life.