Background

As the automotive industry moves towards electrification and decarbonization, fuel cell technology is emerging as a viable alternative in certain areas. Fuel cells are much more energy-dense than current state-of-the-art battery technology, making them an ideal choice for applications that require continuous high-power duty cycles. In addition, fuel cells offer a significant advantage over battery electric vehicles (BEVs), as they have similar refueling times to gasoline and diesel vehicles. These factors make them an ideal zero-tailpipe-emissions choice for heavy-duty (HD) and medium-duty (MD) applications.

Approach

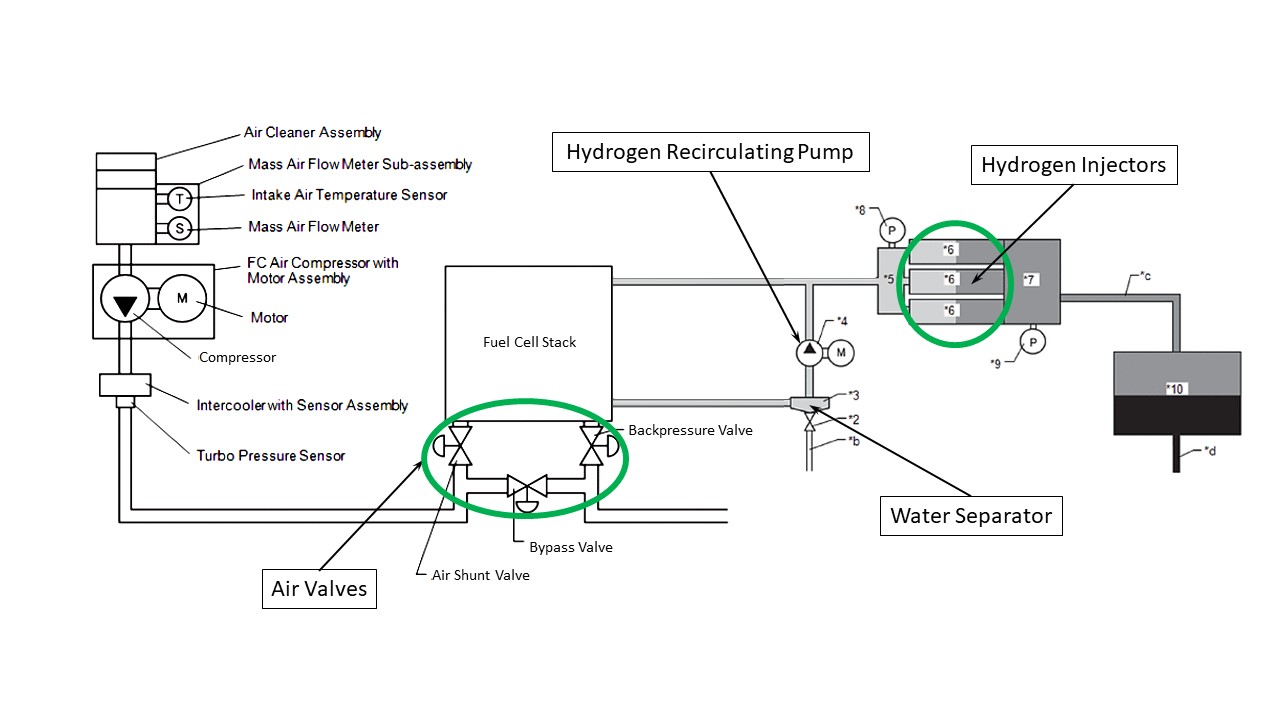

Due to the strong interest from HD/MD OEMs in fuel cell technology and the sophistication of the Mirai unit, the Powertrain Engineering Division conducted a comprehensive benchmarking of a Toyota Mirai fuel cell system under Presidential Discretion Internal Research (PDIR) Project 03.R6171, “Emulation and Enhancement of Balance of Plant Control of the Toyota Mirai PEM Fuel Cells”. In this second phase of the study, the team developed a stand-alone supervisory controller for several of the Mirai's fuel cell actuators (Figure 1). To validate this controller, we operated the Mirai over steady-state and transient driving cycles and compare the results with baseline data.

Figure 1: Schematic of Mirai Fuel Cell System and Actuators of Interest.

Accomplishments

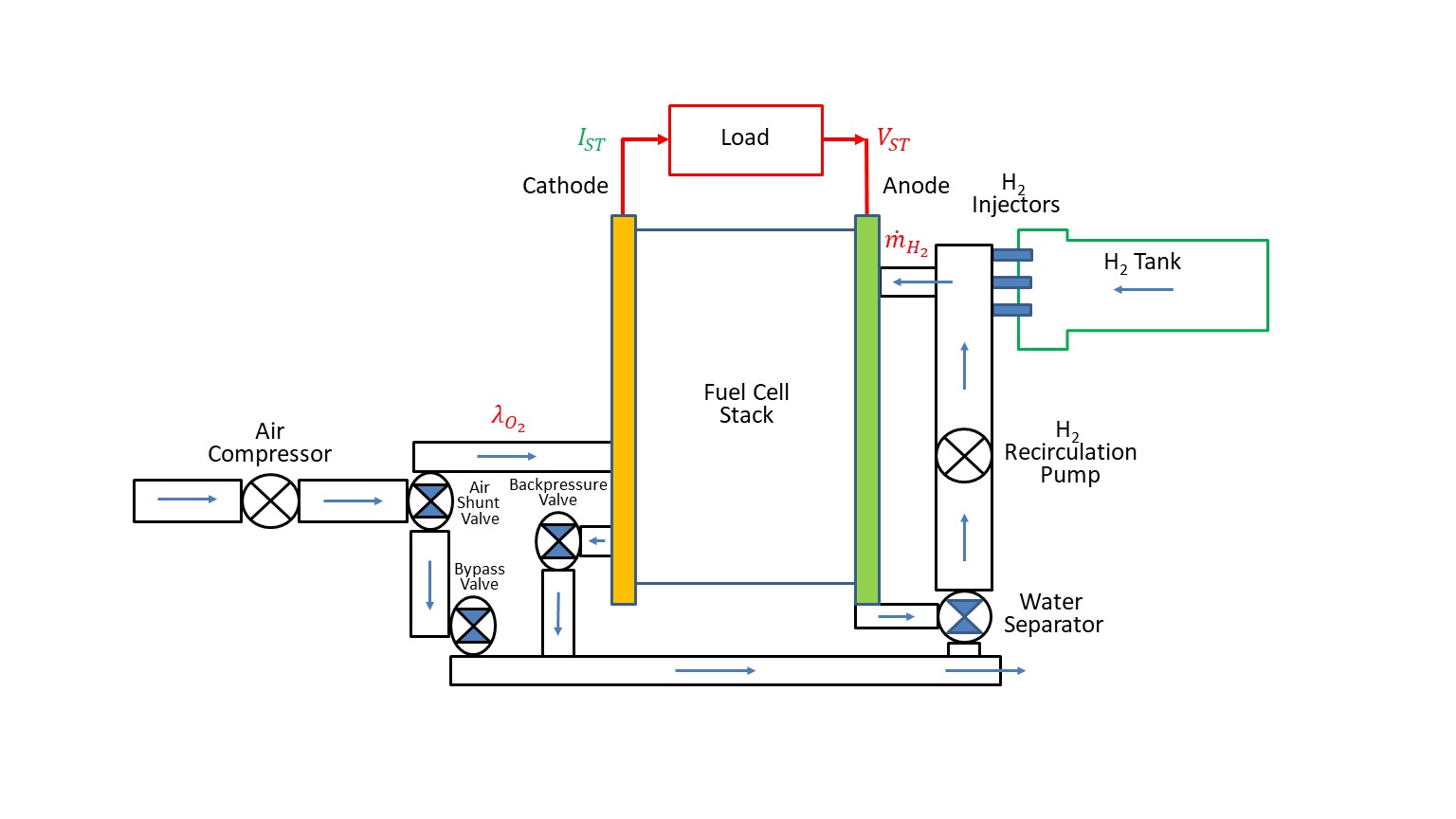

SwRI’s controller was able to replicate the stock control signals for these actuators to within seven percent of the Toyota controllers’ command values for both steady-state and transient cycles. Although we believed Toyota was using a model-based control strategy, we determined their control scheme is primarily driven by feedback from the fuel cell stack current and voltage sensors and pressure sensors at the anode and cathode. Additionally, a novel controller scheme has been developed. This consists of a plant model to estimate the humidity of the fuel cell stack membrane. We believe this novel approach can improve the transient performance of the fuel cell stack.

Figure 2: SwRI Fuel Cell Controller