Background

This Presidential IR&D project was part of a larger Joint Industry Program aimed at developing a Class 8 demonstration vehicle powered by a Hydrogen-fueled Internal Combustion Engine (H2-ICE). The JIP had two primary objectives: 1) Demonstrating the feasibility of converting a vehicle to run on compressed hydrogen fuel and 2) Quantifying the impact on engine emissions of burning hydrogen fuel. The latter objective was of particular importance because nitrogen oxide (NOx) emissions, which are produced by all internal combustion engines, are often cited as a reason to ban internal combustion engines in favor of ‘Zero-Emissions Vehicle’ (ZEV) technologies such as battery-electric or fuel cells. The goal of this project was therefore to demonstrate a substantial reduction in NOx emissions in addition to the CO2 that comes from the carbon-free H2 fuel to make a case for classifying H2-ICE as a ZEV technology. A target was set to meet the MY2027 NOx standard of 0.035 grams per horsepower-hour (g/hp-hr) with a stretch target of meeting voluntary Ultra-low NOx standard of .020 g/hp-hr, representing a 90% reduction from current NOx emissions.

Approach

The overall approach toward this objective was to build on the previous Low-NOx demonstrations for which SwRI has become well known. Under the direction of Chris Sharp (Institute Engineer) we have completed multiple demonstration programs showcasing engine aftertreatment technologies and control strategies for meeting proposed future emissions standards for natural gas and diesel engines. Since the most recent diesel demonstration successfully employed a urea-based Selective Catalytic Reduction (SCR) strategy, this was chosen as the baseline for the H2-ICE demonstration. Figure 1 shows the layout of the diesel Low-NOx aftertreatment system.

Figure 1: Diesel Low-NOx Aftertreatment layout used as a baseline for the H2-ICE program

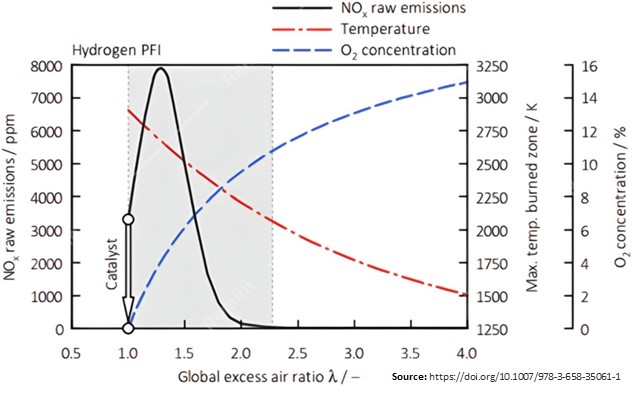

Once the engine was converted to run on hydrogen fuel under separate funding from the JIP, the work of calibration and emission characterization began. This effort involved finding the ideal balance between engine efficiency, engine-out emissions, and exhaust temperatures that would provide the right conditions for optimal performance of the aftertreatment system. Figure 2 shows the trade-off between exhaust temperature and NOx formation versus the excess air ratio lambda (λ). It is clear to see that very low NOx can be achieved by targeting lambda greater than 3, but this is done at the expense of the exhaust temperature. Since peak NOx conversion efficiency within the SCR is achieved at temperatures between 300-400 deg C, a final lambda of 2.4 was selected even though this produced higher engine-out NOx.

Figure 2: NOx and Temperature trade-off versus lambda

The final step involved calibration of the urea dosing system for transient performance. Here again, the team relied heavily on past experience from the Deisel Low-NOx program. SwRI has developed sophisticated physics-based models to determine the precise quantity of urea to inject onto the catalyst for optimal performance. Too little urea can result in lower NOx conversion while too much urea results in ammonia slip which then must be converted back to NOx, meaning there is little margin for error when the objective is to minimize NOx emissions.

Accomplishments

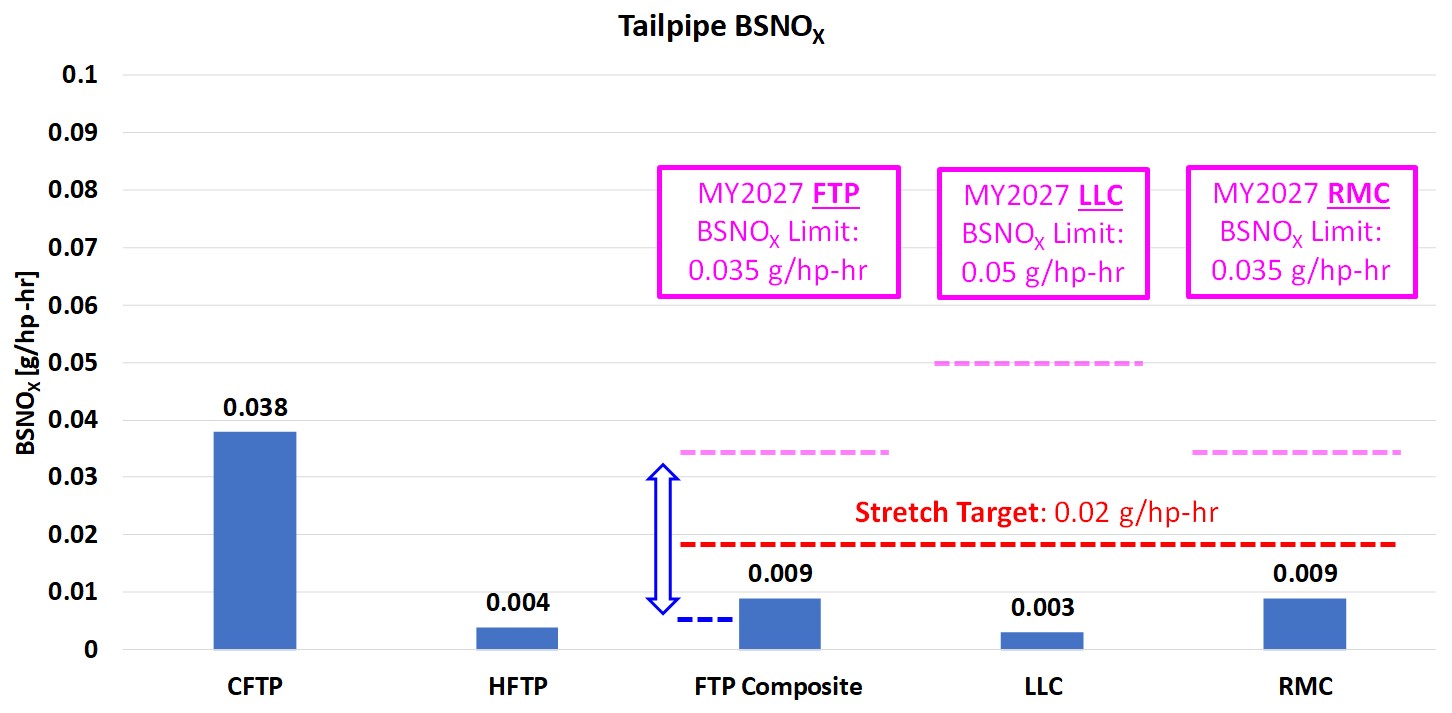

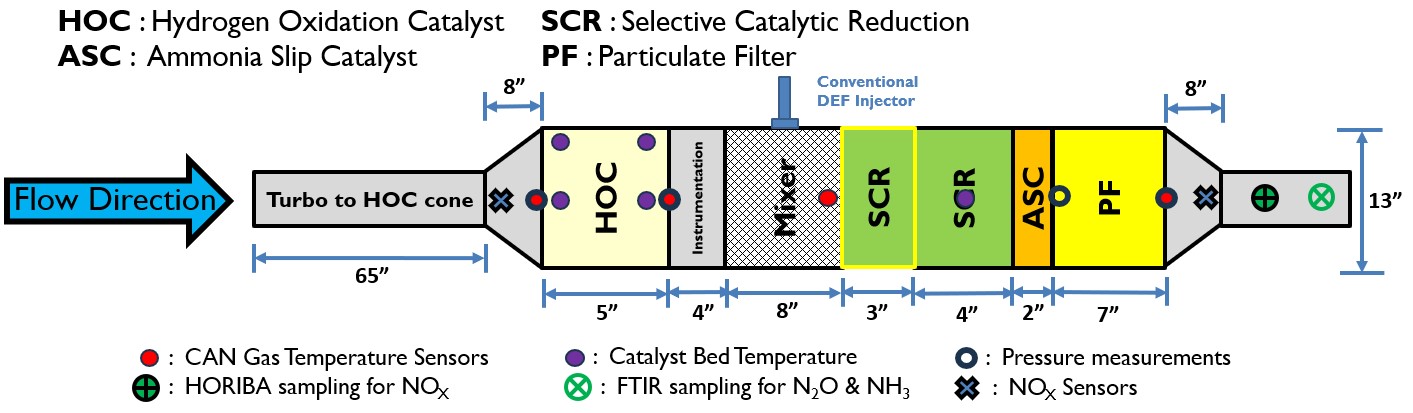

In the end the team not only met, but far exceeded both the primary target as well as the stretch target. Final NOx emissions over the EPA regulatory cycles were all below 0.010 g/hp-hr. Figure 3 shows the final NOx emissions for various test cycles relative to the standard as compared with data from the equivalent Low-NOx Diesel demonstration. The significant decrease in engine-out emissions from the H2-ICE also provided opportunities for simplification of the aftertreatment system. Overall catalyst volume was reduced by nearly half which represents significant cost savings for the vehicle. Figure 4 shows the aftertreatment configuration used for the final demonstration.

Figure 3: Final H2-ICE and Diesel tailpipe NOx emissions relative to program targets

Figure 4: Final H2-ICE Aftertreatment Configuration