Background

While electric motors are more than twice as efficient as internal-combustion engines, they still generate heat due to electrical and frictional losses. This heat is transferred to the oil that lubricates the motor, then to the water-based coolant via a heat exchanger, and finally to the ambient air via the radiator. Higher temperatures increase some losses (e.g. resistive losses in the stator windings) but reduce others (e.g. viscous losses due to the oil). Thus, it is important to understand the effect of temperatures on motor efficiency and the mechanisms of heat transfer within the motor.

Approach

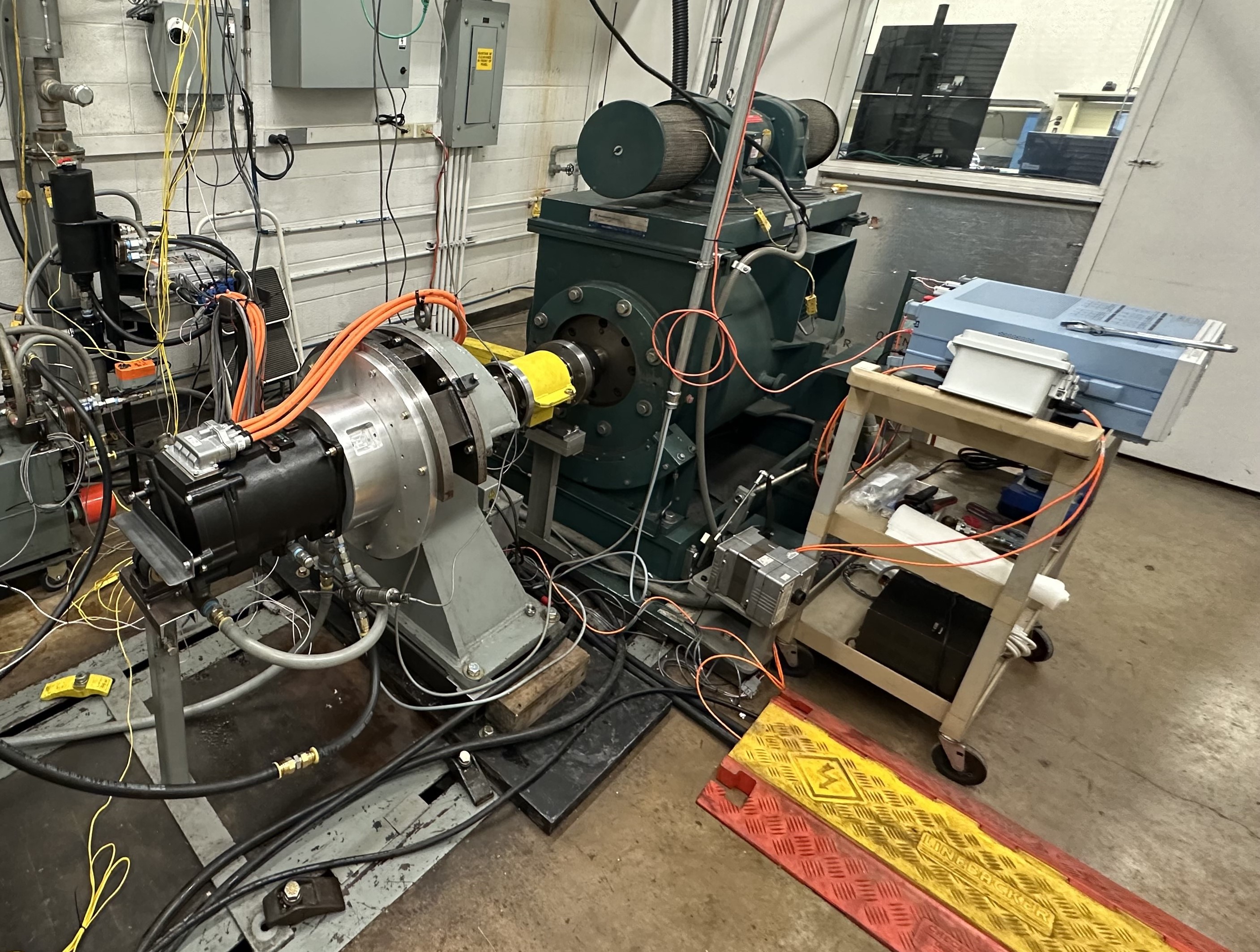

Figure 1: The test motor and inverter mounted on the component dynamometer. The power analyzer is also visible.

The objectives of this project were to separate how the stator-winding temperature and oil temperature affect the motor’s efficiency and to quantify how the physical properties of the oil affect heat transfer and efficiency. Seven oils of widely varied density, specific heat capacity, and viscosity but of comparable thermal conductivity were tested in a production interior-permanent-magnet synchronous motor used in farm equipment. For each oil, and for each of the five 74-kW speed/torque points, the motor was spun to the desired speed by the dyno while commanding zero torque, and then the desired torque was commanded, causing the stator-winding and oil temperatures to ramp up. The nonzero torque command was maintained until the oil and stator-winding temperatures stabilized. The lag between the stator and oil temperatures during the ramp period was used to separately quantify how each temperature impacted efficiency. Data from the period of stable operation was used to quantify the effect of each of the above-mentioned oil parameters on heat-transfer rate and efficiency.

Accomplishments

We successfully quantified the relationships that we targeted in our objectives. In this motor, the oil’s temperature had a larger effect on efficiency than stator’s per unit of temperature change, but because the stator’s temperature varied much more than the oil’s, the stator temperature’s total impact of efficiency was greater. Of the varied oil parameters, only specific heat capacity had a statistically significant impact on heat-transfer rate, and only viscosity had a statistically significant impact of efficiency.