Background

In April 2024, we completed IR&D No. 03-R6356: “Emulation and Enhancement of Balance of Plant Control of the Toyota Mirai PEM Fuel Cells – Phase 2.” During this project, we demonstrated supervisory control of select balance-of-plant (BOP) actuators in a 2021 Toyota Mirai fuel cell vehicle. This marked a major milestone toward our goal of developing a full-authority closed-loop controller to operate the Mirai fuel cell on a test stand.

Before starting Phase 2, we believed Toyota employed a model-based control strategy to manage the fuel cell’s BOP. However, we determined that their control scheme primarily relies on feedback from the fuel cell stack’s current and voltage sensors, along with pressure sensors at the anode and cathode. We have since identified several advanced control strategies to improve stack performance and reduce system losses:

- A humidity model will enhance transient fuel cell performance and reliability.

- Accounting for air transport delay on the cathode side is expected to reduce losses related to the air bypass valve and improve stack efficiency.

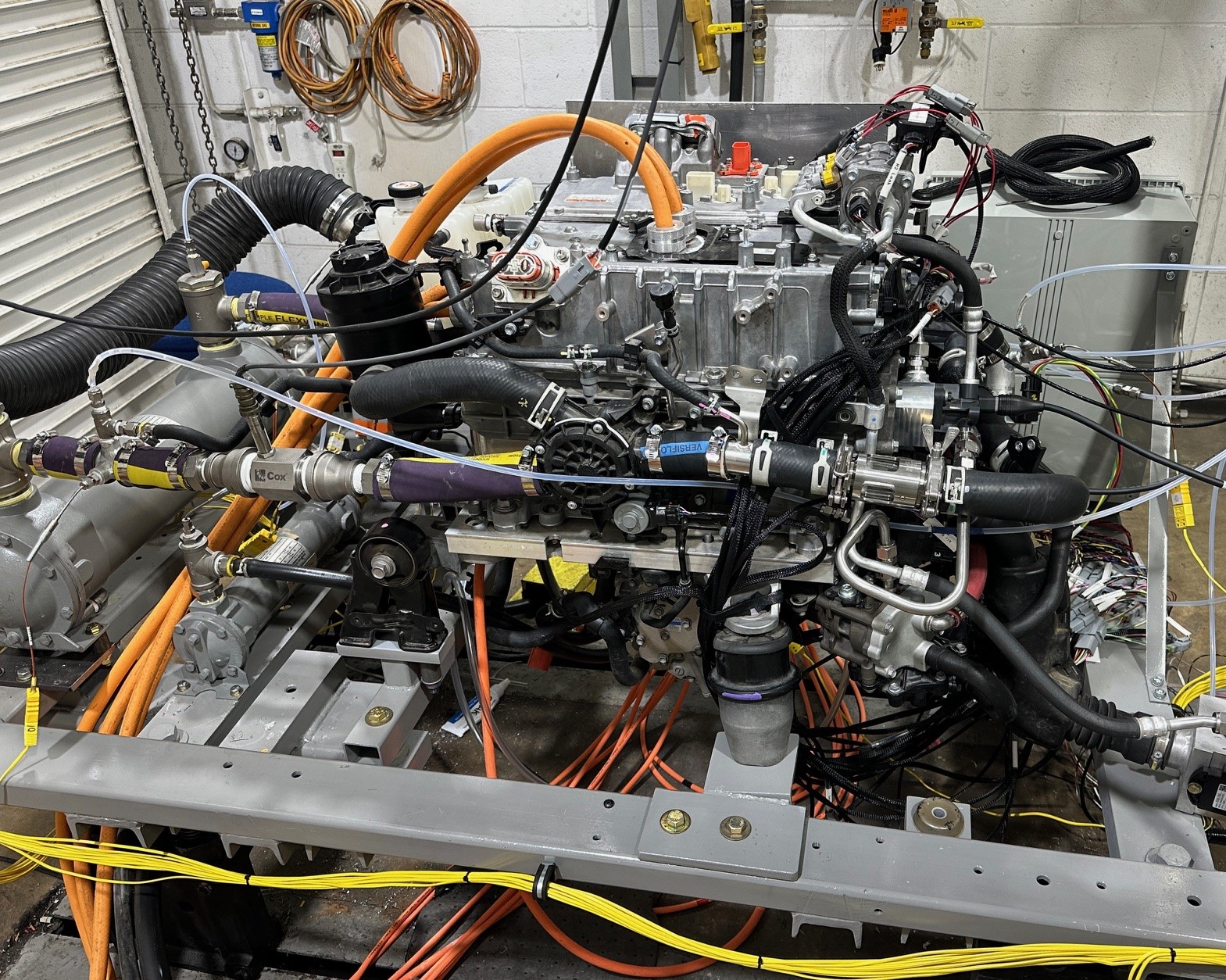

Figure 1: Mirai Fuel Cell System Installed in Test Cell

We now have the tools to control individual fuel cell components and are currently installing a spare Mirai fuel cell system in a test cell. Once this platform is operational, we will develop a methodology for commercial component testing. Additionally, we plan to develop a novel control strategy for active humidity management and incorporate transport delay compensation to improve transient response.

Approach

Building on the accomplishments achieved during Phase 2 of this program, we will demonstrate that the SwRI full-authority controller can operate a Toyota Mirai fuel cell system once it is removed from a vehicle and installed in a test cell, with control over fuel flow rate, air flow rate, and fuel stack temperature. Following system commissioning, we will develop a test protocol to characterize balance of plant component limitations on fuel cell stack performance. This protocol, combined with the full-authority controller, will serve as a testbed for our customers to develop new fuel cell hardware. Finally, we will develop and validate active humidity management and air transport delay compensation using model-based controls.

Accomplishments

We have completed installing the fuel cell system in the test cell and have started the commissioning process. In parallel we have developed additional capabilities for our full-authority controller. Controller development during Phase 2 was conducted in-vehicle with the system at operational temperature, and we relied on the stock vehicle controller commands for system startup and shutdown procedures. Our full-authority controller is now responsible for these activities, as well as system thermal management.