Background

As electric vehicles become more common, the industry is learning more about the unique requirements of the lubricants for these vehicles. One concern is that the inverters that change the DC battery power to AC for the motor can cause current leakage within the driveline. This can cause current to flow through the lubricant. How this affects the friction and wear is not well-understood, and, to date, very few rigs have been adapted to allow for electric current to be applied while testing.

Approach

Two of the tribology test rigs (tribometers) are particularly valid for electric vehicle drivetrain studies. These are the mini traction machine (MTM) and the bearing tester (ARKL). The MTM allows the ball and disc (test samples) to be rotated at different speeds to each other, thereby introducing a slide roll ratio. This can replicate what happens in a gearbox as the teeth are meshing. The ARKL test specimen is a deep groove ball bearing thrust washer and can be used to study the effect of current flow through a bearing and race. Using techniques developed during a previous IR where we electrified a block on ring test rig, both the MTM and ARKL have been electrified.

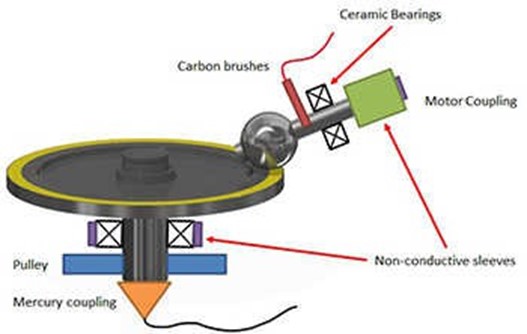

Figure 1: Schematic of electrified Mini Traction Machine.

Accomplishments

The MTM has been electrified as shown schematically in Figure 1 and the test matrix completed. The ARKL electrification has been completed and several runs undertaken to confirm it is working correctly. It has been observed that the wear increases when AC or DC current is applied across the test samples and that the MTM produced Stribeck curves (friction measurements) become disrupted, and repeatability is lost between consecutive runs.