Background

The process of bagging potato chips in food manufacturing commonly encounters seal failures. Often the result of product fragments getting caught in the seal, these failures lead to issues like staleness or contamination. Currently, pressure decay is used to test seal integrity, but this method can damage the product, especially with hard chip varieties. Incorporating polarization imaging, a contactless inspection approach can be developed to detect the seal integrity of potato chip bags by reducing glare and specular reflections over conventional cameras.

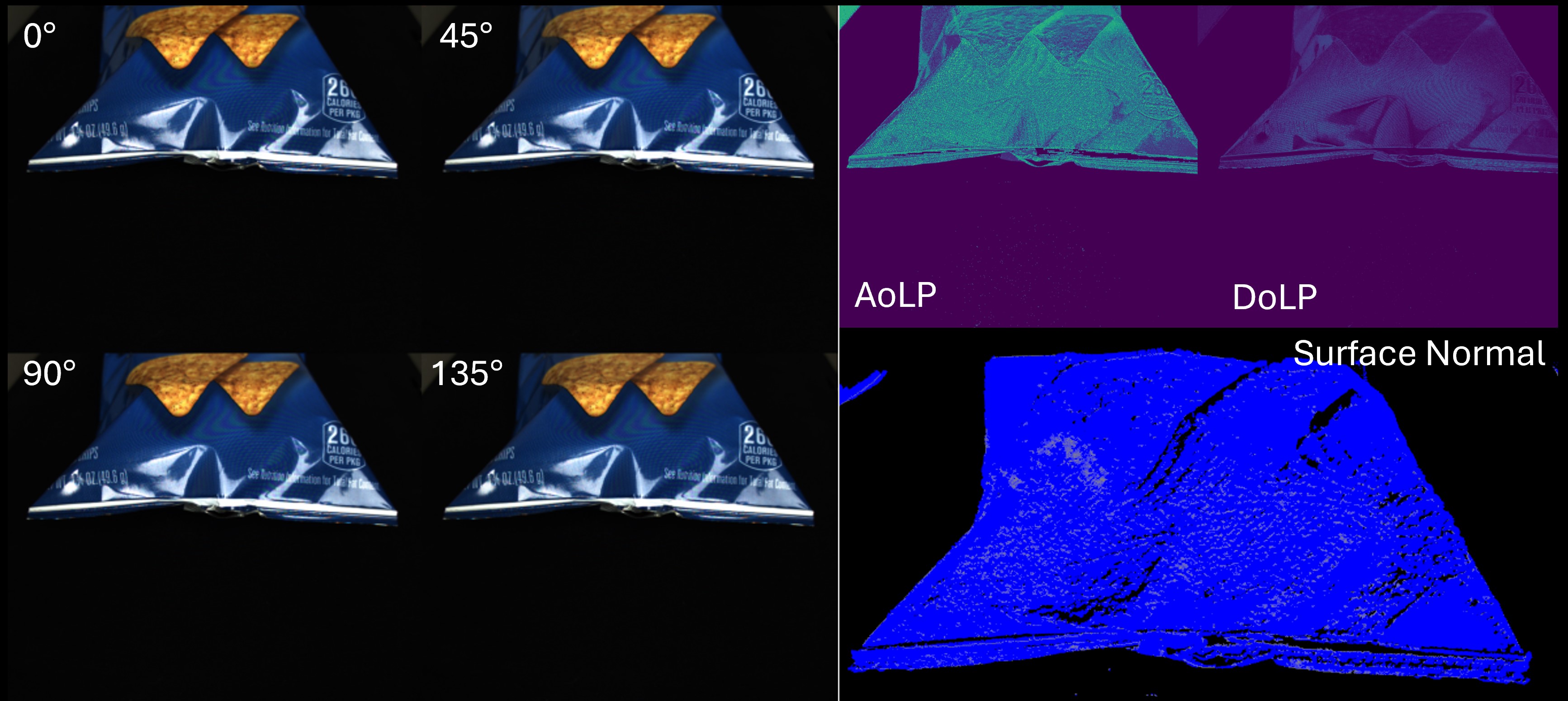

Figure 1: Polarization images with extracted features.

Approach

This research applied a micro-polarizing imager with the EfficientNet deep neural network to train a system to detect package seal defects. The micro-polarizing imager generated a unique set of pixel level features that included the degree of linear polarization (DoLP), angle of linear polarization (AoLP) and estimated surface normals. These features used model surface reflections, increased edges, and include pixel level depth information. An EfficientNet convolutional neural network was optimized to categorize a polarized image as containing a package with a seal defect or not. This model was trained to recognize disparities in the seal surface structure and discern correlations in intensity variations between good and defective seals.

Accomplishments

The goal was to detect package defects using split-pixel polarization features to enhance detection accuracy to improve the quality control in the production process. The team evaluated images of various types of defects that included tears and openings captured via the micro-polarizing imager. The team developed a software package to capture data, to analyze the polarization features, and to evaluate the detection performance. The detection system achieved greater than 96% accuracy for detecting polarized images with defective seals. In addition, the system can generate a geometric surface profile to provide richer data while minimizing reflections from the packaging material.